Aqueous coating composition and preparation method thereof

A mixture and modification technology, applied in the direction of coating, etc., can solve the problems of light coating color, affecting coating performance, affecting the storage stability of additive-dispersed coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

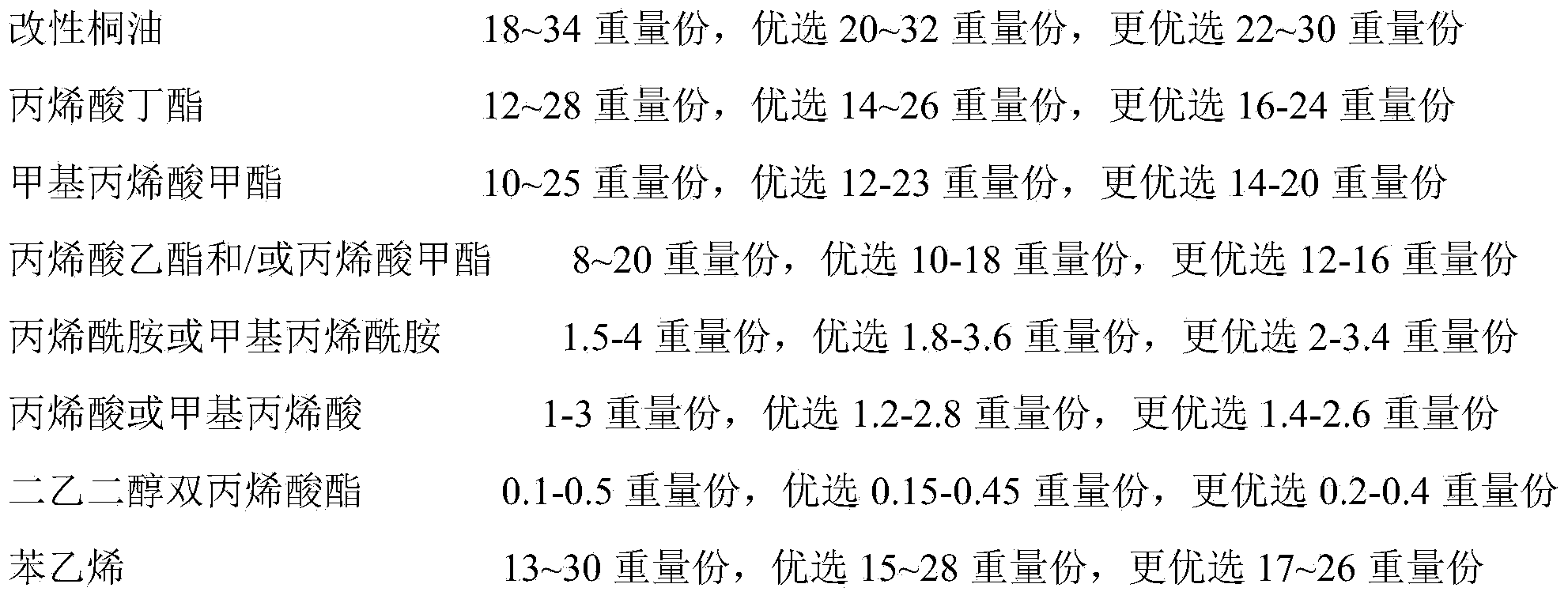

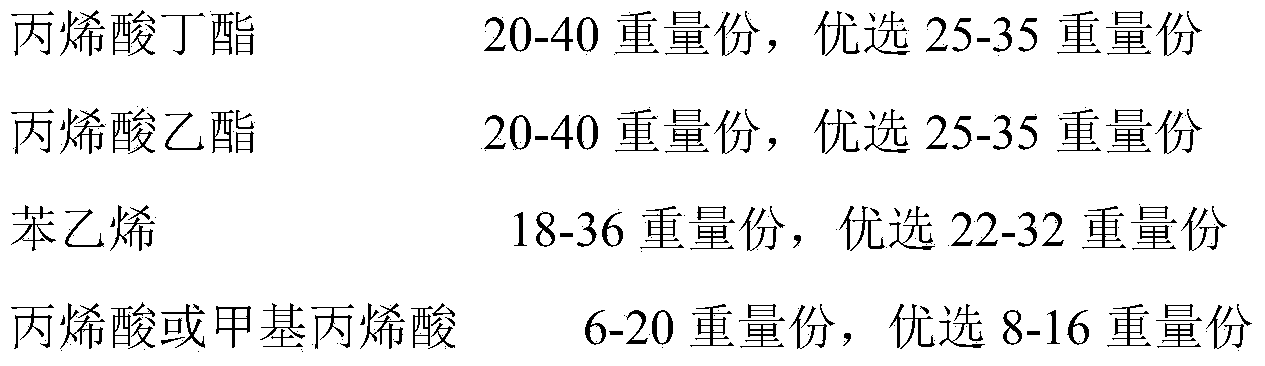

Method used

Image

Examples

preparation example 1-

[0079] Preparation Example 1 - Preparation of Modified Tung Oil 1:

[0080] Refined tung oil (glyceride content 71wt%) and sodium maleic anhydride derivative sulfonate (sodium maleic anhydride derivative sulfonate, product name M12) were reacted at 140°C for 2 hours under nitrogen protection in a weight ratio of 100:70 to obtain addition Reaction product - modified tung oil 1.

preparation example 2-

[0081] Preparation Example 2 - Preparation of Modified Tung Oil 2:

[0082] Refine tung oil and 2-methyl-2-propene-1-sodium sulfonate (sodium2-methyl-2-propene-1-sulfonate (SMS)) according to the weight ratio of 100:80 under nitrogen protection at 150 ° C for 1.5 hours , to obtain the addition reaction product-modified tung oil 2.

preparation example 3-

[0083] Preparation Example 3 - Preparation of Modified Tung Oil 3:

[0084] Refined tung oil reacted with sodium allyl hydroxyalkyl sulfonate (SAHS) at a weight ratio of 100:80 at 140°C for 2 hours under nitrogen protection to obtain the addition reaction product - modified tung oil 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com