Waterborne acrylic resin and packaging container coating and preparation method

A water-based acrylic and acrylic technology, applied in the chemical industry, can solve the problems of thick coating foaming and poor fullness, and achieve the effects of improving resin weather resistance, fullness and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

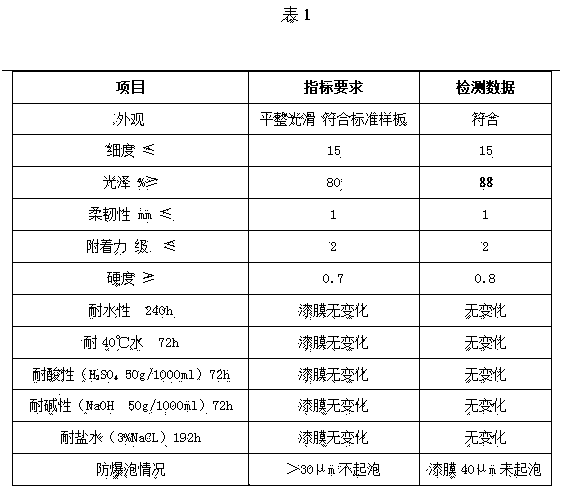

Examples

Embodiment 1

[0032] Embodiment 1, prepare waterborne acrylic resin

[0033] The amount of raw materials is as follows: butanol (Jiangsu Sanmu) 20kg; 1,1-dimethyl-1-heptyl carboxyglycidyl ester (Shell) 10kg; acrylic acid (Beijing Dongfang) 4kg; butyl acrylate (Beijing Dongfang) 15kg; Ethylene (PetroChina) 20kg; hydroxypropyl acrylate (Nanjing) 10kg; 2-ethylhexyl acrylate (Beijing Dongfang) 12kg; tert-butyl benzoyl peroxide (Lanzhou Auxiliary Factory) 1kg; 2-amino-2 - Methyl-1-propanol (Dow Chemical) 5 kg; make up the balance with deionized water.

[0034] Formulated from 1,1-dimethyl-1-heptylcarboxyglycidyl ester, acrylic acid, butyl acrylate, styrene, hydroxypropyl acrylate, 2-ethylhexyl acrylate, tert-butyl benzoyl peroxide The mixed solution formed; put butanol into the bottom of the reactor and raise the temperature to 125°C; gradually add the mixed solution dropwise and react for 180 minutes to make it fully polymerized. Lower the temperature below 60°C for neutralization, the ...

Embodiment 2

[0035] Embodiment 2, preparation waterborne acrylic resin

[0036] The amount of raw materials is as follows: butanol (Jiangsu Sanmu) 25kg; 1,1-dimethyl-1-heptyl carboxyglycidyl ester (Shell) 7kg; acrylic acid (Beijing Dongfang) 6kg; butyl acrylate (Beijing Dongfang) 9kg; Ethylene (PetroChina) 13kg; hydroxypropyl acrylate (Nanjing) 15kg; 2-ethylhexyl acrylate (Beijing Dongfang) 20kg; tert-butyl benzoyl peroxide (Lanzhou Auxiliary Factory) 1kg; 2-amino-2 - Methyl-1-propanol (Dow Chemical) 4 kg; make up the balance with deionized water.

[0037] Formulated from 1,1-dimethyl-1-heptylcarboxyglycidyl ester, acrylic acid, butyl acrylate, styrene, hydroxypropyl acrylate, 2-ethylhexyl acrylate, tert-butyl benzoyl peroxide The mixed solution formed; put butanol into the bottom of the reactor and raise the temperature to 125°C; gradually add the mixed solution dropwise and react for 180 minutes to make it fully polymerized. Lower the temperature below 60°C for neutralization, th...

Embodiment 3

[0038] Embodiment 3, prepare waterborne acrylic resin

[0039] The amount of raw materials is as follows: butanol (Jiangsu Sanmu) 30kg; 1,1-dimethyl-1-heptyl carboxyglycidyl ester (Shell) 5kg; acrylic acid (Beijing Dongfang) 10kg; butyl acrylate (Beijing Dongfang) 8kg; Ethylene (PetroChina) 10kg; hydroxypropyl acrylate (Nanjing) 9kg; 2-ethylhexyl acrylate (Beijing Dongfang) 10kg; tert-butyl benzoyl peroxide (Lanzhou Auxiliary Factory) 1kg; 2-amino-2 - Methyl-1-propanol (Dow Chemical) 5 kg; make up the balance with deionized water.

[0040] Formulated from 1,1-dimethyl-1-heptylcarboxyglycidyl ester, acrylic acid, butyl acrylate, styrene, hydroxypropyl acrylate, 2-ethylhexyl acrylate, tert-butyl benzoyl peroxide The mixed solution formed; put butanol into the bottom of the reactor and raise the temperature to 125°C; gradually add the mixed solution dropwise and react for 180 minutes to make it fully polymerized. Lower the temperature below 60°C for neutralization, the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com