Wire-cut electric discharge machine wire transport mechanism capable of realizing accurate closed-loop control on tension of electrode wire

A technology of closed-loop control and electric discharge wire, which is applied in the direction of electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve the problem of inaccurate real-time dynamic control of tension, and achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

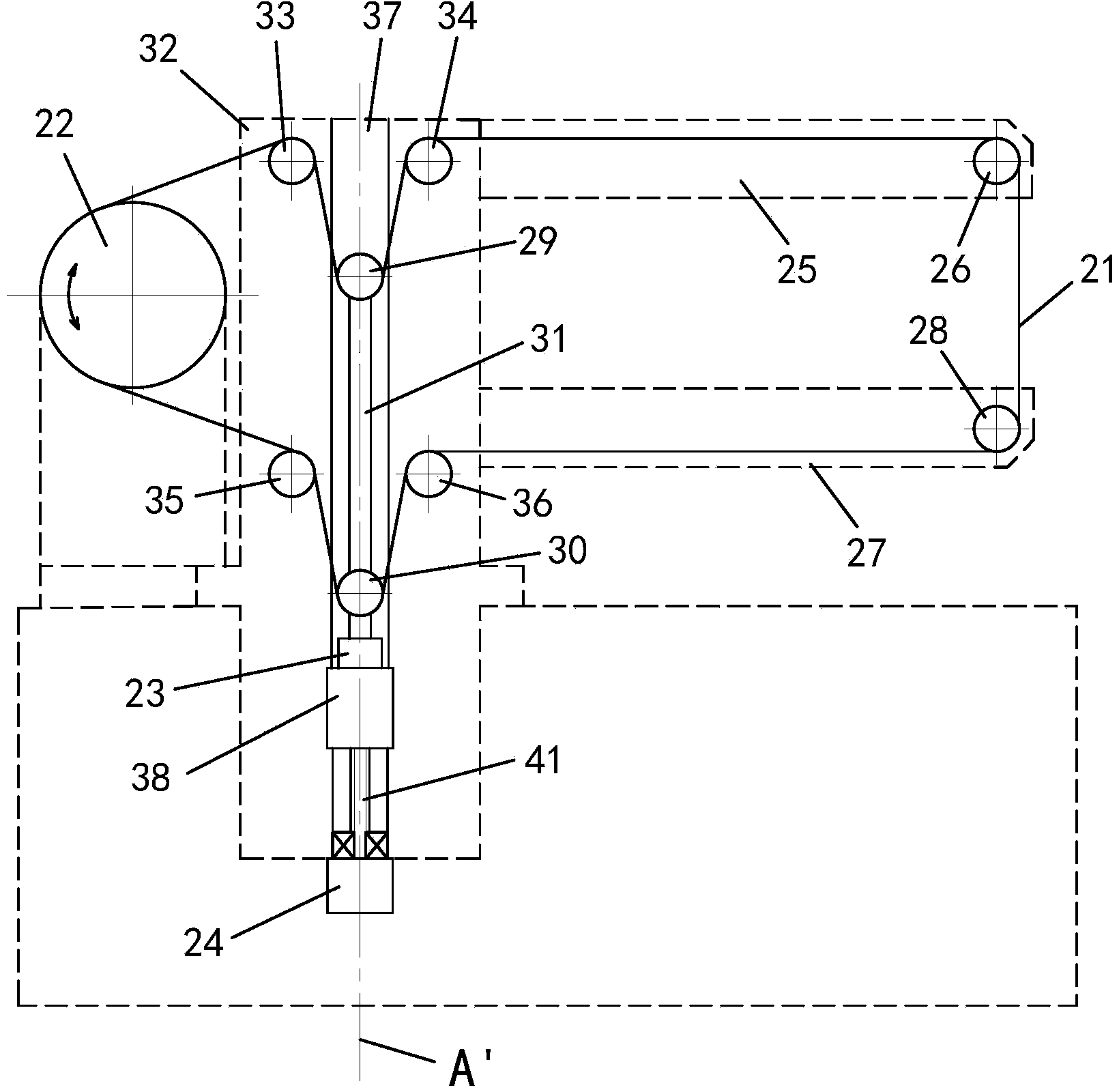

[0036] Embodiment one: see figure 2 , Figure 5 -6 shows:

[0037] A wire feeding mechanism of a wire electric discharge machine for precise closed-loop control of electrode wire tension, see figure 2 As shown, it includes an annular closed electrode wire 21, a wire storage tube 22, several reversing wheels, a load cell 23, a driving device 24, an upper tension wheel 29 and a lower tension wheel 30, which are located at the end of the upper wire frame 25 of the wire cutting machine. The upper guide wheel 26 and the lower guide wheel 28 located at the end of the lower wire frame 27 of the wire cutting machine.

[0038] see figure 2 As shown, the upper tension wheel 29 and the lower tension wheel 30 are arranged vertically apart from each other, and the two are connected by a connecting plate 31 . The upper tensioning wheel 29, the lower tensioning wheel 30 and the connecting plate 31 form a tensioning part; the tensioning part is slidably connected to the column 32 of th...

Embodiment 2

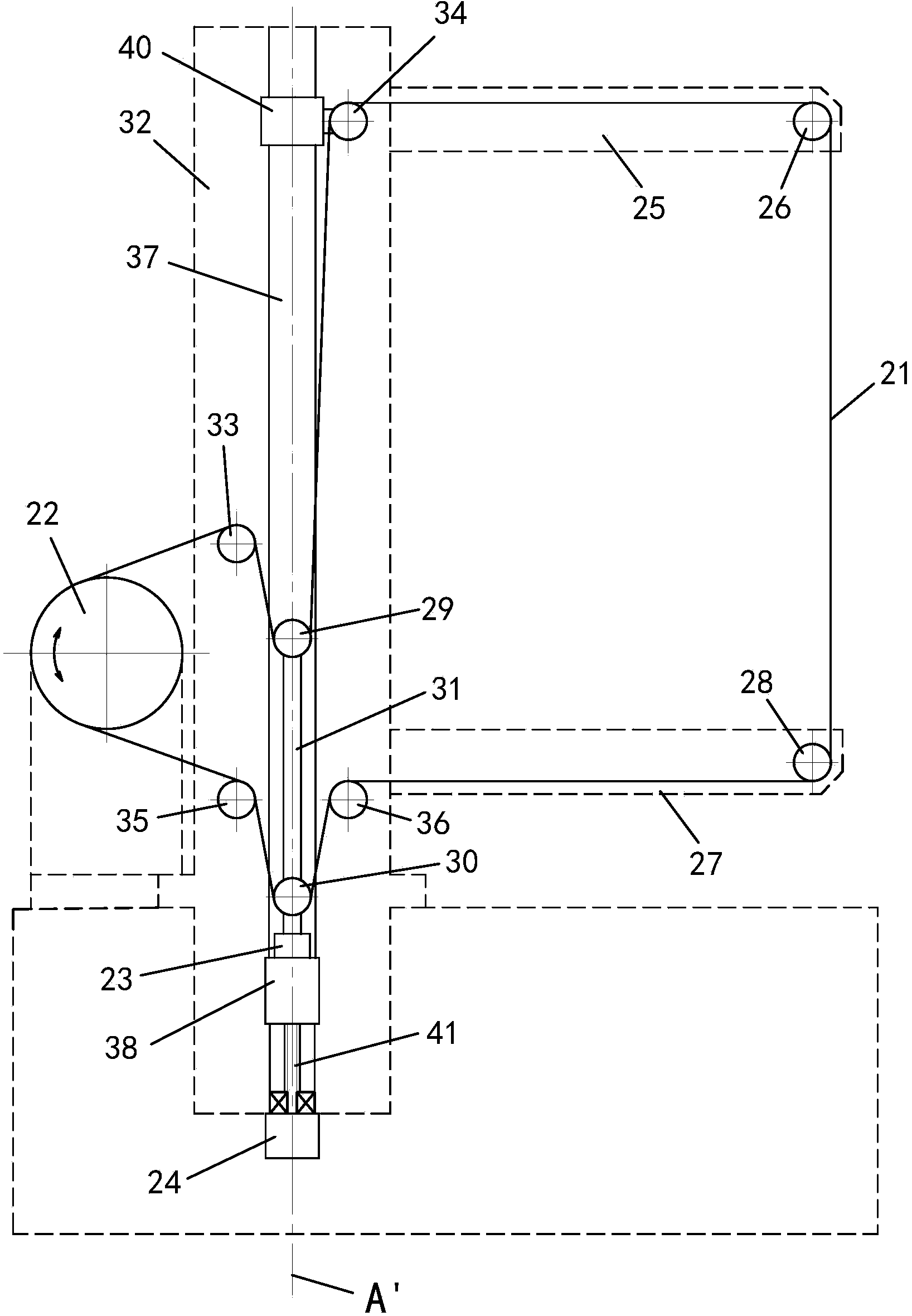

[0045] Embodiment two: see image 3 Shown:

[0046] A wire feeding mechanism of a wire electric discharge machine for precise closed-loop control of electrode wire tension. The difference from Embodiment 1 is that there is a third slider 40 on the linear slide rail 37, and the upper right reversing wheel 34 It is fixed on the third slider 40 so that the upper right reversing wheel 34 can move up and down to follow the upper guide wheel 26 for position adjustment. In this way, while the upper guide wheel 26 is adjusted to meet the requirements for cutting and processing workpieces of different heights, the upper right reversing wheel 34 is moved synchronously to realize the situation that the upper and lower halves of the ring-shaped closed electrode wire 21 are all in a horizontal state. unchanged, so that the state that the upper tension wheel 29 detects the wire tension of twice the upper half remains unchanged. Upper left reversing wheel 33 and two lower reversing wheels ...

Embodiment 3

[0049] Embodiment three: see Figure 4 Shown:

[0050] A wire feeding mechanism of a wire electric discharge machine for precise closed-loop control of electrode wire tension. The difference from Embodiment 1 is that there is a second slider 39 on the linear slide rail 37, and the connecting plate 31 is fixedly connected to on the second slider 39 . The addition of the second slide block 39 increases the stability of the movement of the tensioning member.

[0051] Others are the same as those in Embodiment 1, and will not be repeated here.

[0052] The above-mentioned embodiments are only examples for illustration, and in practice, the following detailed variation schemes can also be adopted:

[0053] 1. The driving device 24 can use a linear servo motor, and the mover of the linear servo motor is fixedly connected to the end of the load cell 23, so that parts such as the screw 41, the nut and the first slider 38 are omitted.

[0054] 2. The linear slide rail 37 adopts lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com