Micro large-speed-ratio speed reducer and needle gear positioning flange mounting method thereof

A technology for positioning flanges and reducers, which is applied to gear transmissions, mechanical equipment, transmissions, etc., and can solve the problems of small size of reducer and large transmission ratio of reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

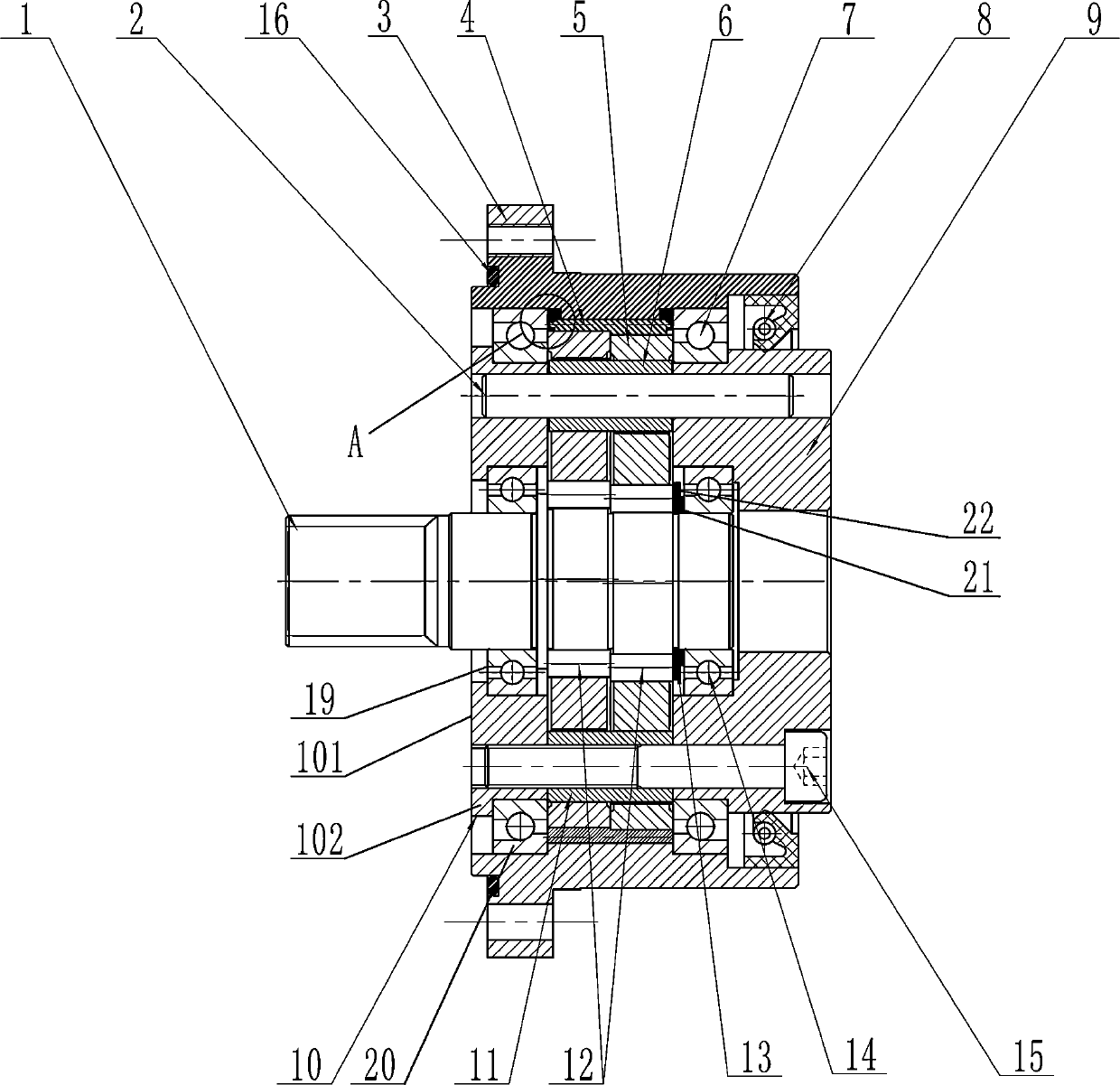

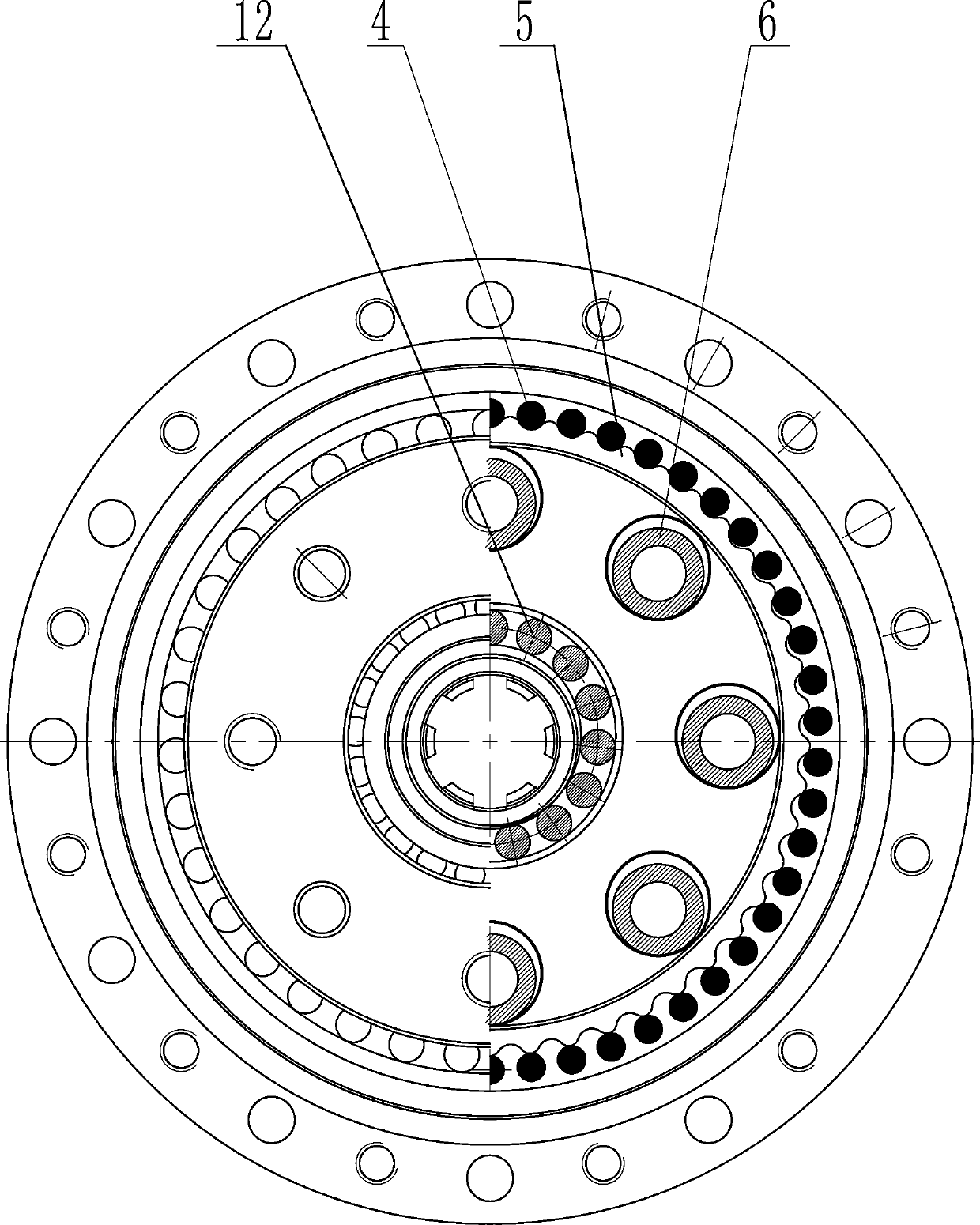

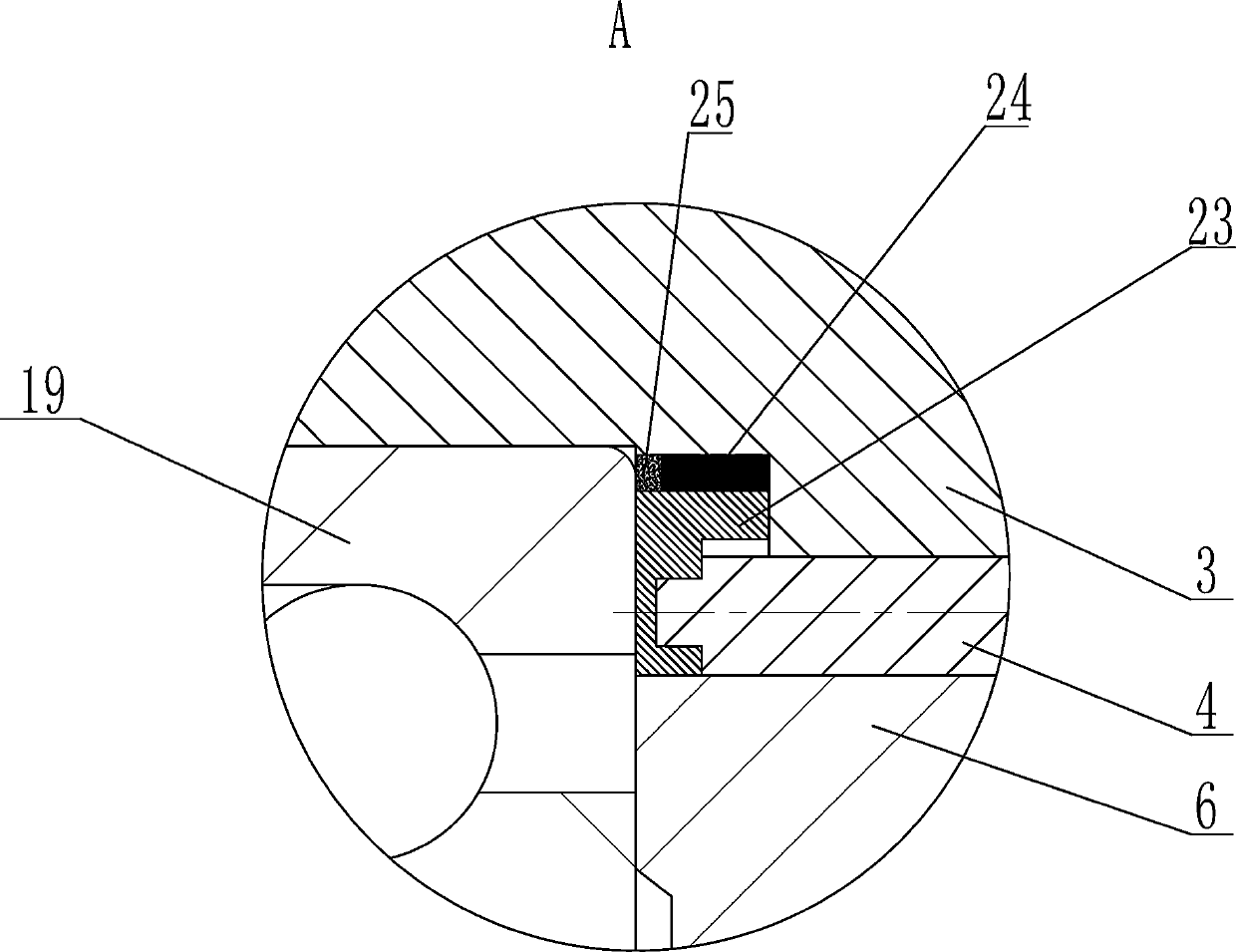

[0036] like Figure 1~9 As shown, a miniature high-speed ratio reducer includes a casing 3, an output seat 9 and an input shaft 1. The input shaft 1 is fixed with two eccentric wheels with a phase difference of 180°, and the two eccentric wheels pass through the crank bearing 12 respectively. Connected with a cycloidal wheel 5, a plurality of needle-toothed pins 4 are arranged along the circumference on the inner wall of the casing 3, and the needle-toothed pins 4 are intermittently meshed with two cycloidal wheels 5, and the inside of the casing 3 is provided with a needle-toothed positioning flange 23, A plurality of pin tooth pin positioning holes 232 are provided on the surface of the inner ring of the pin tooth positioning flange 23, the pin tooth positioning flange 23 is located at both ends of the pin tooth pin 4, and the two ends of the pin tooth pin 4 are provided with positioning cylinders 41 , the positioning cylinder 41 is placed in the pin tooth pin positioning ho...

Embodiment 2

[0048] A miniature high-speed-ratio reducer and its pin-tooth positioning flange installation method, the method comprising:

[0049] 1) After finishing the pin tooth positioning flange 23, knurling is performed on its surface, and knurling is processed after finishing. The knurling plays a better role in stability in the interference fit, and also prevents the flat surface from collapsing after the fit. loose phenomenon;

[0050] 2) Install one of the needle-tooth positioning flanges 23, install the positioning pin 24 on the positioning groove 31 inside the housing 3, and align the flange positioning groove 231 of the needle-tooth positioning flange 23 with the positioning pin 24 on the positioning groove 31. Cooperate to position the pin-tooth positioning flange 23, which plays the role of positioning and also plays the role of anti-rotation;

[0051] 3) After positioning, cold fit the pin tooth positioning flange 23. After the installation is completed, install the pin too...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com