Preparation method and use of catalyst for preparation of cyclopentanone through hydrogenation of water phase furfural

A technology for preparing cyclopentanone and catalyst, which is applied to the preparation of heterocyclic compounds, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of cumbersome preparation process of carbon aerogel, collapse of molecular sieve shares, and difficult removal of carriers, etc. The operating conditions are easy to control, the industrial prospect is good, and the catalytic effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method for a catalyst for the hydrogenation of furfural in aqueous phase to cyclopentanone, comprising the steps of:

[0032] Step 1. Press Na 2 O: Al 2 o 3 : SiO 2 :H 2 O molar ratio is 10~16:1:10~16:180~370, mix sodium metaaluminate, sodium hydroxide, water glass and deionized water evenly, stir for 0.5h, and age for 24~72h to obtain Y-type molecular sieve Directing agent; in the calculation of molar ratio, Na 2 The quality of O refers to the Na in the three substances of sodium hydroxide, sodium metaaluminate and water glass. 2 Sum of O, Al 2 o 3 The quality refers to the Al in sodium metaaluminate 2 o 3 mass of SiO 2 The mass refers to SiO in water glass 2 mass, H 2 The mass of O refers to the H in water glass and deionized water 2 The sum of O; wherein, the molar weight of Al in sodium metaaluminate is expressed as Al 2 o 3 In terms of, the molar amount of Na is expressed as Na 2 In terms of O; the molar weight of Na in sodium hydroxid...

Embodiment 1

[0041] (1) Mix 0.68g of sodium metaaluminate, 3.68g of sodium hydroxide, 14.86g of water glass and 18mL of deionized water evenly, stir for 0.5h and then age at room temperature for 24h to obtain a Y-type molecular sieve directing agent.

[0042] (2) Dissolve 3.11g of sodium metaaluminate in 58mL of deionized water, add 1.94g of sodium hydroxide, then slowly add 32.51g of water glass dropwise, then add 0.9g of 3-aminopropyltriethoxysilane and 9.31g of step (1) The prepared Y-type molecular sieve directing agent was stirred at room temperature for 3 hours to obtain an aluminosilicate gel.

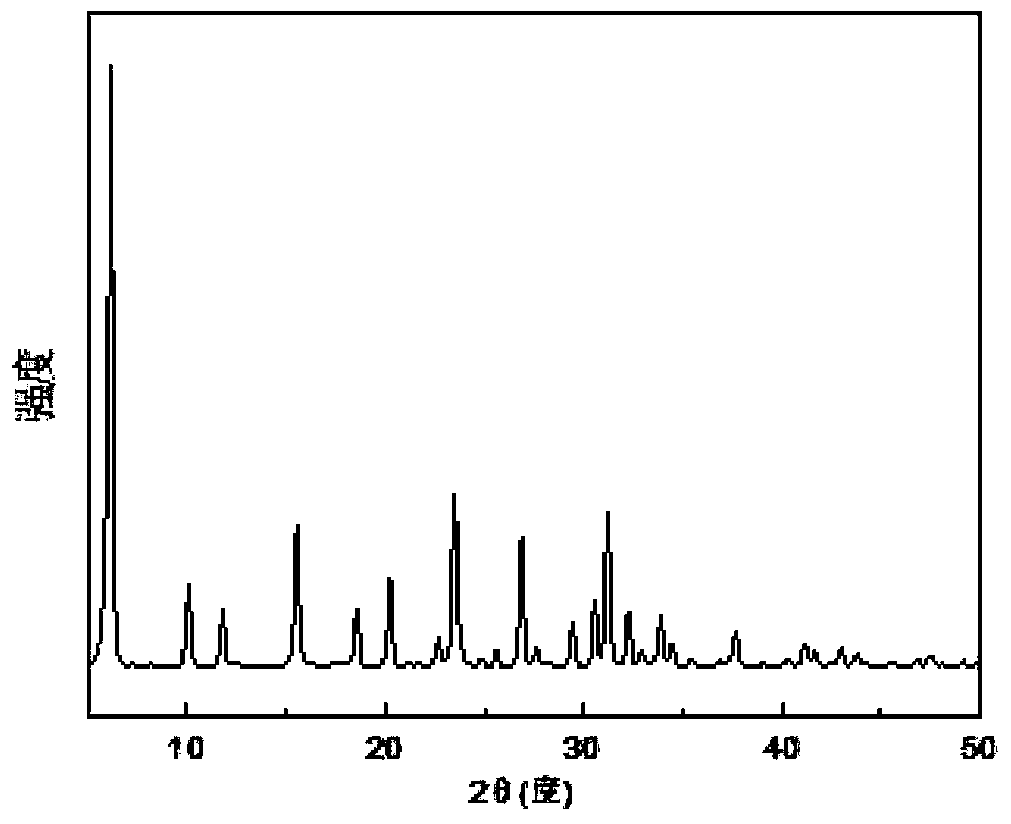

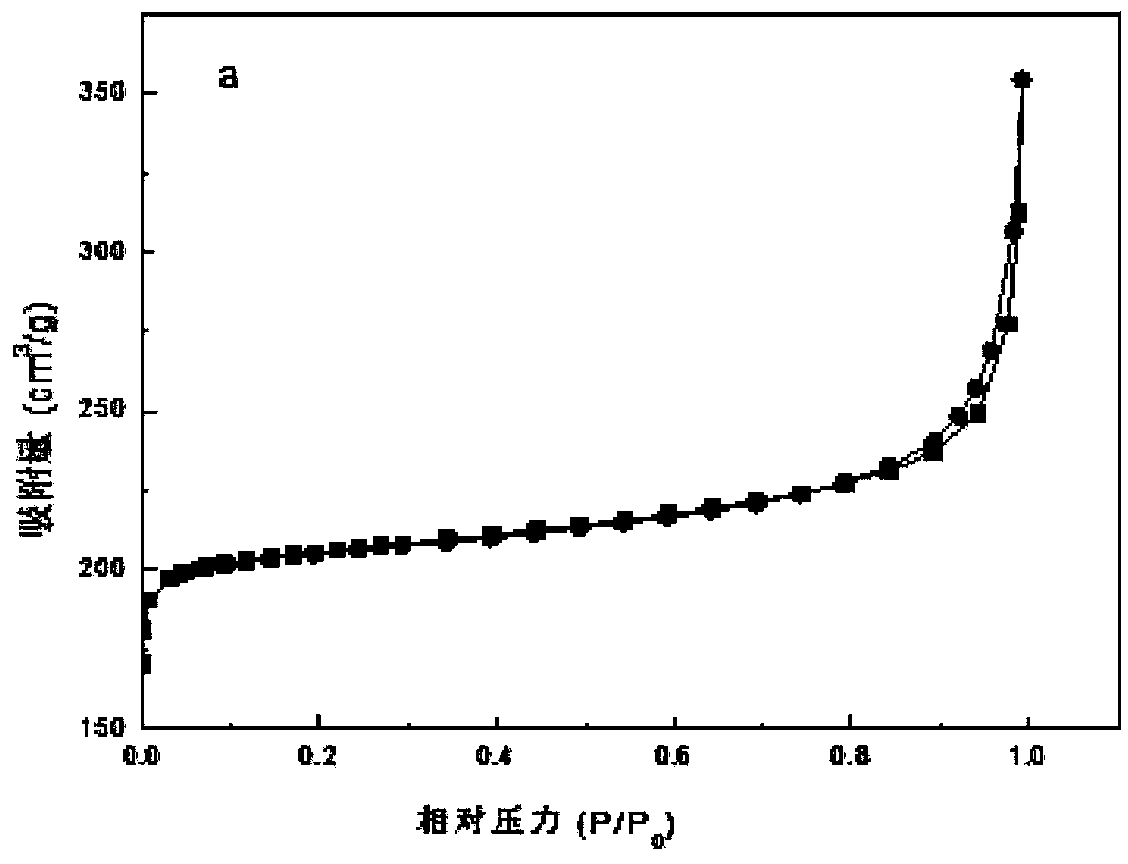

[0043] (3) Put the obtained aluminosilicate gel into a hydrothermal kettle for crystallization at 90° C. for 15 hours. After the crystallization, the solid product was suction filtered, washed and dried, and then calcined in a muffle furnace at 550° C. for 5 hours to remove the mesoporous template agent to obtain a multi-stage Y-type molecular sieve.

[0044] (4) the obtained multi-stage po...

Embodiment 2

[0047] (1) Mix 0.89g of sodium metaaluminate, 2.65g of sodium hydroxide, 18.22g of water glass and 15mL of deionized water evenly, stir for 0.5h and then age at room temperature for 36h to obtain a Y-type molecular sieve directing agent.

[0048] (2) Dissolve 1.46g of sodium metaaluminate in 34mL of deionized water, add 1.528g of sodium hydroxide, then slowly add 18.99g of water glass dropwise, then add 1.6g of sodium alginate and 7.35g of sodium alginate prepared in step (1) Y-type molecular sieve guide agent, stirred at room temperature for 3 hours to obtain aluminosilicate gel.

[0049] (3) Put the obtained aluminosilicate gel into a hydrothermal kettle for crystallization at 110° C. for 20 h. After the crystallization, the solid product was suction filtered, washed and dried, and then calcined in a muffle furnace at 550° C. for 5 hours to remove the mesoporous template agent to obtain a hierarchically porous Y molecular sieve.

[0050] (4) the obtained multi-stage porous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com