Light-duty high-strength corrosion-resisting on-site bus cable

A field bus, high-strength technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of miniaturization, light weight, high reliability, easy cracking and aging of insulation, and thick wire insulation extrusion for mobile equipment. Achieve the effects of superior crack resistance, excellent crack resistance and ultra-thin insulation thickness

Inactive Publication Date: 2014-09-24

YANGZHOU YAGUANG CABLE

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the transmission lines for 1553B bus systems of mobile equipment such as aerospace, tanks, and armored vehicles mainly use F46, F40, and F26 insulated wires. The wires have thick insulation, large volume, and heavy weight. The insulation is easy to crack and age, and the safety and reliability performance is poor

With the technological innovation and development of aerospace, tanks, armored vehicles and other equipment, the requirements for the safety performance, radiation resistance, insulation performance and volume weight of the cable wiring system are getting higher and higher. The current F46, F40, F26 insulated wires It has been difficult to meet the requirements of miniaturization, light weight and high reliability of mobile devices

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

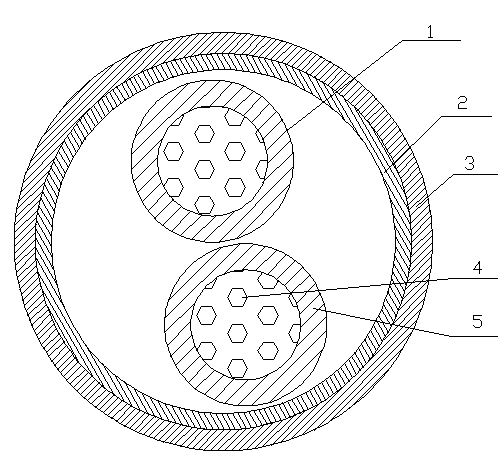

[0007] like figure 1 As shown, the present invention includes two groups of insulated wire cores 1, and a braided shielding layer 2 and a sheath layer 3 are sequentially arranged outside the insulated wire cores 1, and each group of insulated wire cores 1 includes concentrically twisted multi-strand flexible wires 4, respectively. The outer side of the concentrically twisted multi-strand flexible wire 4 is wrapped with an insulating layer 5 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Disclosed is a light-duty high-strength corrosion-resisting on-site bus cable which relates to the technical field of cable manufacturing. The cable includes two groups of insulating wire cores. A braided shielding layer and a sheath layer are arranged sequentially outside the insulating wire cores. Each group of insulating wire core includes a plurality of strands of flexible wires which are twisted concentrically. The plurality of strands of flexible wires which are twisted concentrically are externally wrapped with insulating layers. The light-duty high-strength corrosion-resisting on-site bus cable is simple and reasonable in structure and has the characteristics of being high in strength, capable of resisting corrosion of oil products and solvents, small in volume, light in weight, radiation resistant and high in reliability and the like.

Description

technical field [0001] The invention relates to the technical field of cable manufacture. Background technique [0002] At present, the transmission lines for 1553B bus systems of aerospace, tanks, armored vehicles and other mobile equipment mainly use F46, F40, and F26 insulated wires. The wires have thick insulation, large volume, and heavy weight. The insulation is easy to crack and age, and the safety and reliability performance is poor. With the technological innovation and development of aerospace, tanks, armored vehicles and other equipment, the requirements for the safety performance, radiation resistance, insulation performance and volume weight of the cable wiring system are getting higher and higher. The current F46, F40, F26 insulated wires It has been difficult to meet the requirements of miniaturization, light weight and high reliability of mobile devices. Contents of the invention [0003] The object of the present invention is to provide a lightweight hig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B7/00H01B7/17

Inventor 曾廷环鲁永林李忠诚陈小龙鲁学军邵玉和

Owner YANGZHOU YAGUANG CABLE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com