high density fabric

A high-density, fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of poor weaving, different densities, air permeability, less defects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

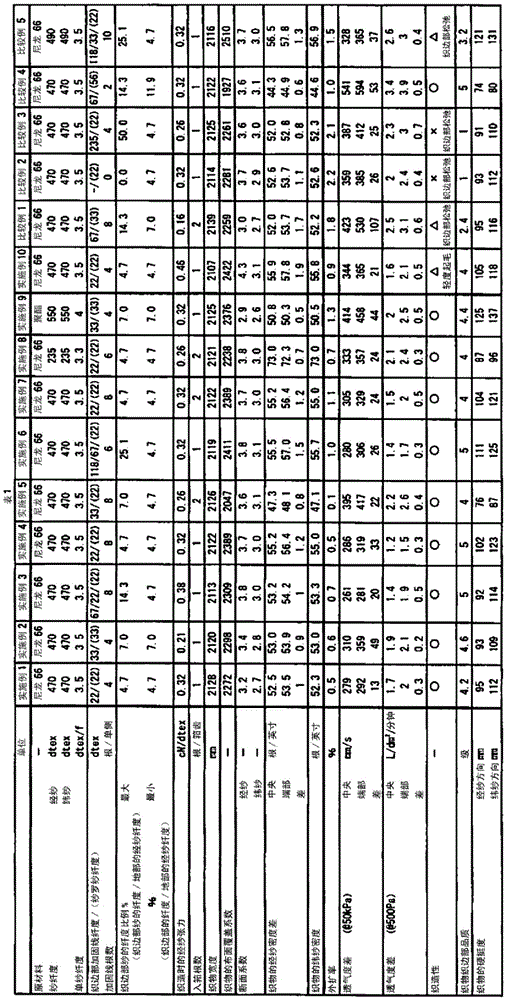

Examples

Embodiment 1

[0089] Fibers having a strength of 8 cN / dtex obtained by melt-spinning and thermally drawing polyhexamethylene adipamide resin were used as warp and weft of the fabric. The fiber had a fineness of 470 dtex, 136 single yarns, a boiling water shrinkage rate of 7.0%, and an interlacing number of 10 / m by the water immersion method. The warp yarns are warped without twisting or sticking, and a warp beam with 4382 warp yarns is produced. The number of reinforcing threads at the selvedge part is 4 on one side and 8 on both sides, and the fineness of the reinforcing threads is 22dtex. In addition, a full-width temple made of nylon resin is used, and a convex spindle with a diameter of 0.5 mm is uniformly and densely attached to the surface.

[0090] A water-jet loom was used as the loom, and the warp tension was set to 0.32cN / dtex. The loom rotation speed was 700rpm, and the weft was woven using the same yarn as the warp. Next, the gray cloth obtained is washed with water, passed co...

Embodiment 2

[0093] Gray fabrics were obtained in the same manner as in Example 1, except that the warp tension on the loom was 0.21 cN / dtex and the fineness of the reinforcing threads was 33 dtex. After the woven fabric was washed with water and passed through a drying cylinder, it was treated in the same manner as in Example 1 except that it was heat-set without passing through the heat calendering process, to obtain a woven fabric.

[0094] The evaluation results of the obtained fabrics are shown in Table 1. The spread rate was good at 0.6, the warp density difference of the fabric was as small as 0.9 yarns / 2.54cm, the air permeability and air permeability difference between 50kPa and 500Pa were also good, and the weavability was also good. It should be noted that the airbag produced from the obtained high-density fabric also showed good results in internal pressure maintaining performance and airbag folding performance.

Embodiment 3

[0096] The warp tension on the loom is set to 0.38cN / dtex, and the fineness of the reinforcing thread is 4 threads of 67dtex and 4 threads of 22dtex from the center toward the end at the selvage portion on one side, and 4 threads of 22dtex at the selvage portion on the other side. Gray fabrics were obtained in the same manner as in Example 1 except that 8 pieces of 22dtex were used. The woven gray cloth is washed with water and passed through a drying cylinder to obtain a fabric.

[0097] The evaluation results of the obtained fabrics are shown in Table 1. The spread rate was good at 0.7, the warp density difference of the fabric was as small as 1.0 yarns / 2.54cm, the air permeability and air permeability difference between the fabric at 50kPa and 500Pa were also good, and the weavability was also good. It should be noted that the airbag produced from the obtained high-density fabric also showed good results in internal pressure maintaining performance and airbag folding perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com