Fishing net braiding machine

A weaving machine and fishing net technology, which is applied in the field of fishing net weaving machines, can solve the problems of weft gap, uneven density, low efficiency, etc., and achieve the effect of improving quality, improving weaving efficiency, and uniform weaving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

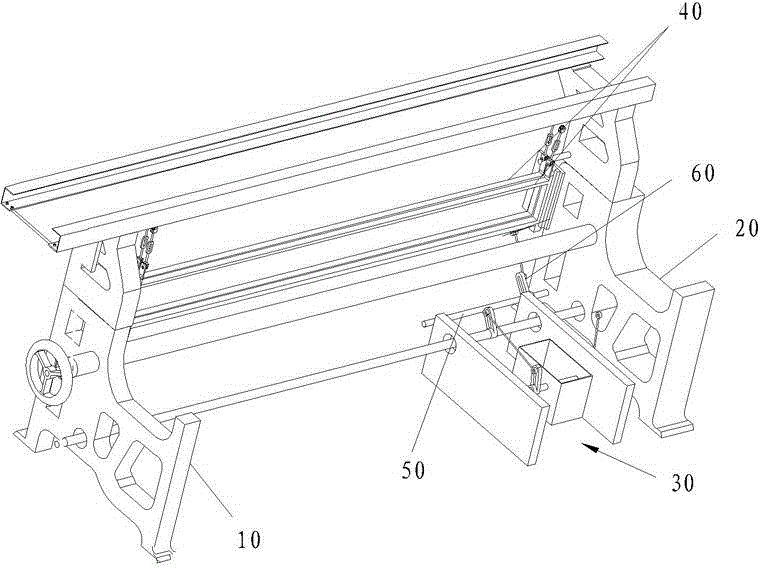

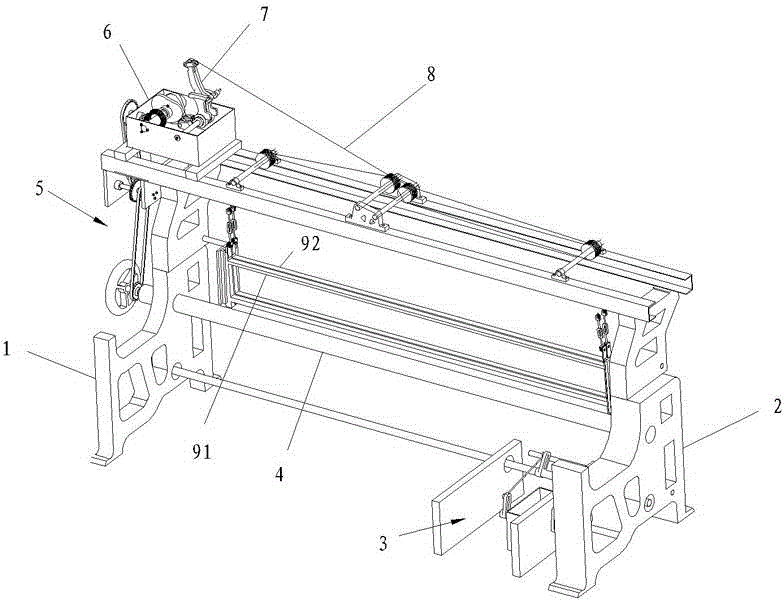

[0027] A fishing net weaving machine, comprising a left frame 1, a right frame 2, a beating power drive device 3, a main machine bent shaft 4, a transmission assembly 5, a gear box 6, a knife device 7, a steel wire rope 8, and two heald frames 91 , 92.

[0028] The beating-up power driving device 3 provides the guiding weft shuttle beating-up power, which is the same as the existing fishing net weaving machine, without structural changes, so it will not be repeated here.

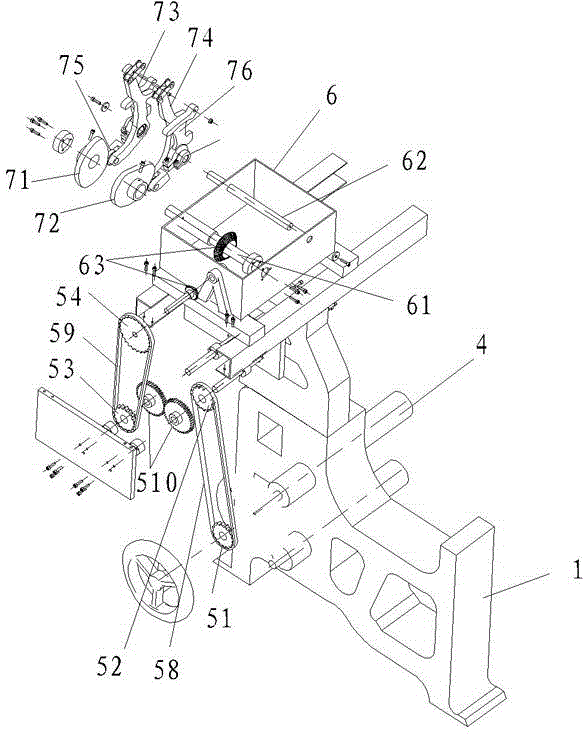

[0029] The bent shaft 4 of the main engine is supported between the left frame 1 and the right frame 2, and is connected with external power components. The bending shaft 4 of the main engine transmits the power to the knife beating device 7 in the gear box 6 through the transmission assembly 5 .

[0030] In the present embodiment, transmission assembly 5 mainly inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com