Environment-friendly sizing agent assistant, and preparation method and application of assistant

A technology of additives and slurry, which is applied in the field of environmentally friendly slurry additives and its preparation, can solve problems such as environmental burden, unclean desizing, and secondary hairiness, so as to reduce energy consumption, benefit environmental protection, and reduce warp breakage The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

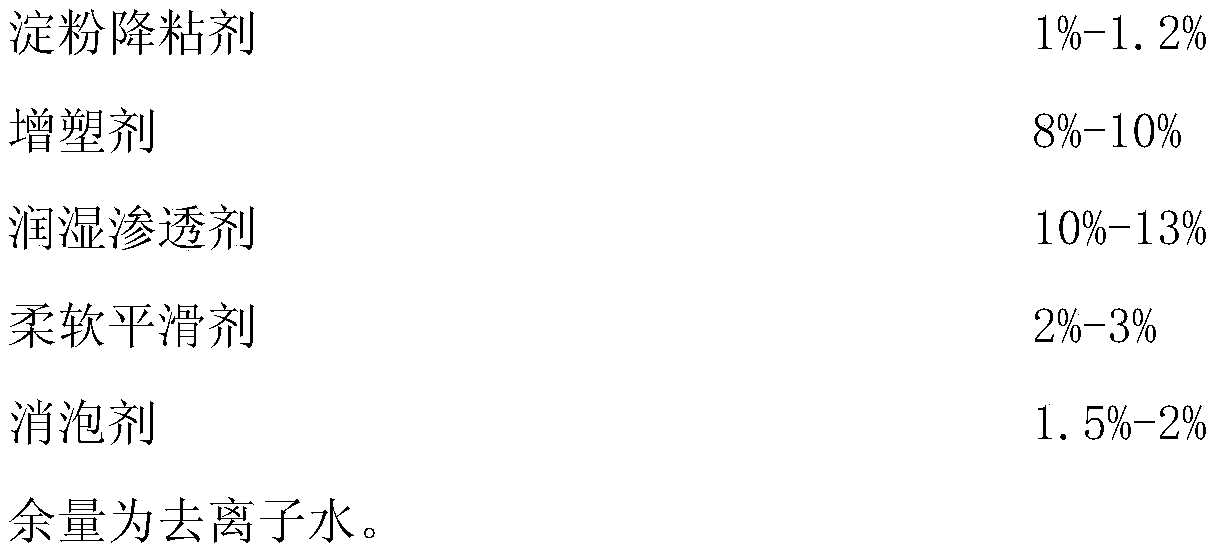

[0040] An environmentally friendly slurry additive, prepared from the following raw materials in mass percentage:

[0041]

[0042] Preparation of environmentally friendly slurry additives:

[0043] (1) Add a certain amount of deionized water into a three-necked flask with a stirrer and a condensing device, turn on the reaction device, and set the temperature of the water bath within the range of 45°C-55°C;

[0044] (2) In the range of 45°C-55°C, add a certain amount of viscosity reducer, wetting and penetrating agent and softening and smoothing agent into a three-necked flask, stir for 30 minutes, and then transfer to a beaker for use;

[0045] (3) transfer the emulsion to be used in step 2 into a high-speed emulsifier for emulsification for 30 minutes, then add a certain amount of plasticizer and defoamer to the emulsifier and blend for 20 minutes to obtain a translucent milky white emulsion;

[0046] (4) Finally, add a small amount of ammonia water to adjust the pH valu...

Embodiment 2

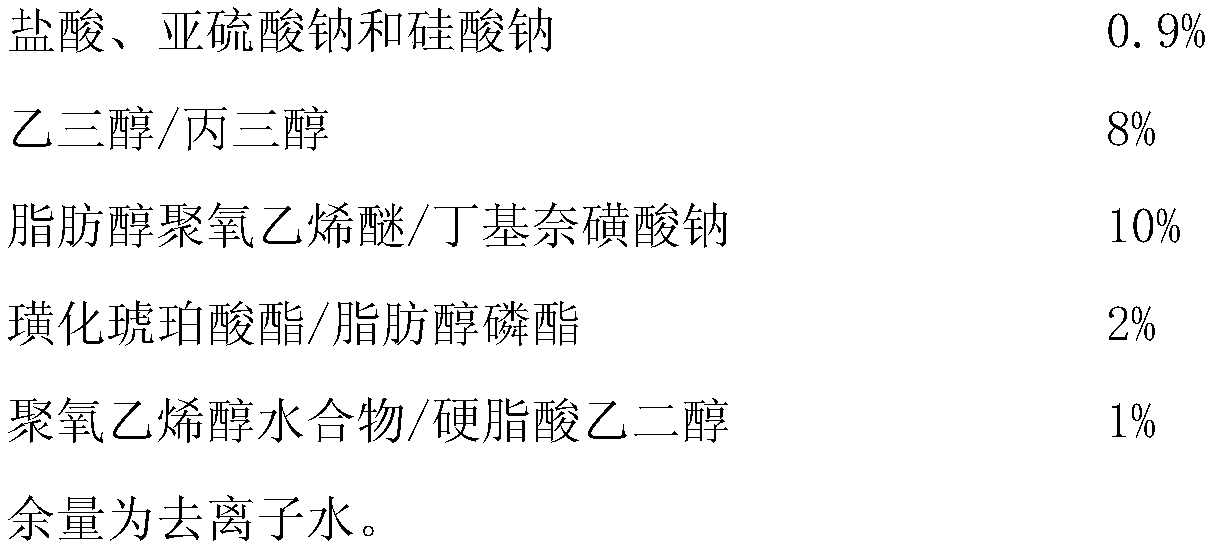

[0063] An environment-friendly size auxiliary agent, including a main material and an auxiliary agent, wherein the main material is refined corn starch, and the auxiliary agent is made from the following raw materials in mass percentage:

[0064]

[0065]

[0066] Preparation of environmentally friendly slurry additives:

[0067] The preparation method of the environmentally friendly slurry additive is the same as in Example 1.

[0068] Prepare slurry:

[0069] The method for preparing the slurry in this embodiment is the same as that in Embodiment 1.

[0070] Apply the slurry prepared in this embodiment to the weaving process of polyester-cotton products:

[0071] The polyester-cotton yarn is wound onto the warp beam through the warping machine (the warping speed is 300-400m / min), and the yarn on the warp beam passes through the sizing tank. The temperature of the slurry is 90°C, and the sizing pressure is 23KN. The speed is 75m / min. When drying by the drying cylinde...

Embodiment 3

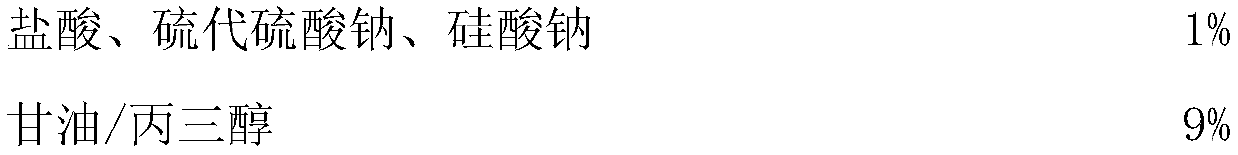

[0076] An environmentally friendly slurry additive, including a main ingredient and an auxiliary agent, wherein the main ingredient is refined corn starch, and the auxiliary agent is made from the following raw materials in mass percentage

[0077]

[0078]

[0079] Preparation of environmentally friendly slurry additives:

[0080] The preparation method of the environmentally friendly slurry additive is the same as in Example 1.

[0081] Prepare slurry:

[0082] The method for preparing the slurry in this embodiment is the same as that in Embodiment 2.

[0083] Apply the slurry prepared in this embodiment to the weaving process of polyester-cotton products:

[0084] The polyester-cotton yarn is wound onto the warp beam through the warping machine (the warping speed is 300-400m / min), and the yarn on the warp beam passes through the sizing tank. The temperature of the slurry is 95°C, and the sizing pressure is 25KN. The speed is 80m / min. When drying by the drying cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com