Weaving method of high-temperature-resistant composite material container pre-woven body

A composite material, high temperature resistant technology, applied in the field of three-dimensional weaving, can solve the problems of uneven density, difficult weaving, poor mechanical properties, etc., to achieve high versatility, good mechanical properties, and ensure the effect of structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

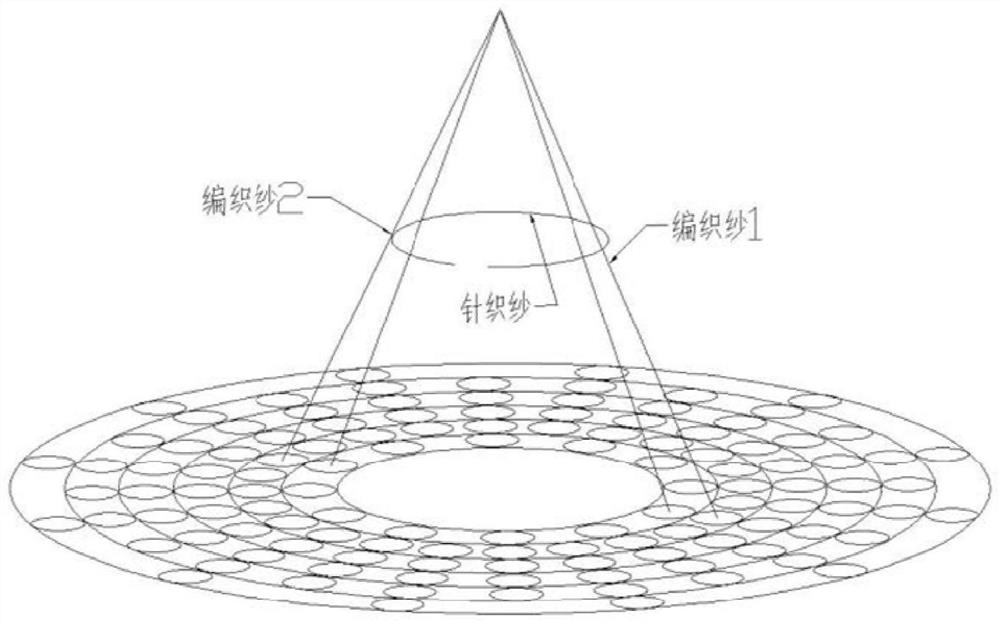

[0024] In this embodiment 1, based on figure 1 Explains how to hang yarn and where to knit yarn.

[0025] Such as figure 1 As shown, the two knitting yarns are U-shaped and crossed to hook each other, and the two ends of the knitting yarn 1 are respectively hung on the innermost ring on the same side and the yarn carrier of the adjacent ring, and the knitting yarn 2 is connected with the knitting yarn. Yarn 1 is hung symmetrically at the other end, and all weaving yarns can be hung in groups of two in this way. The gaps between the yarns are where the knitting yarns are added.

Embodiment 2

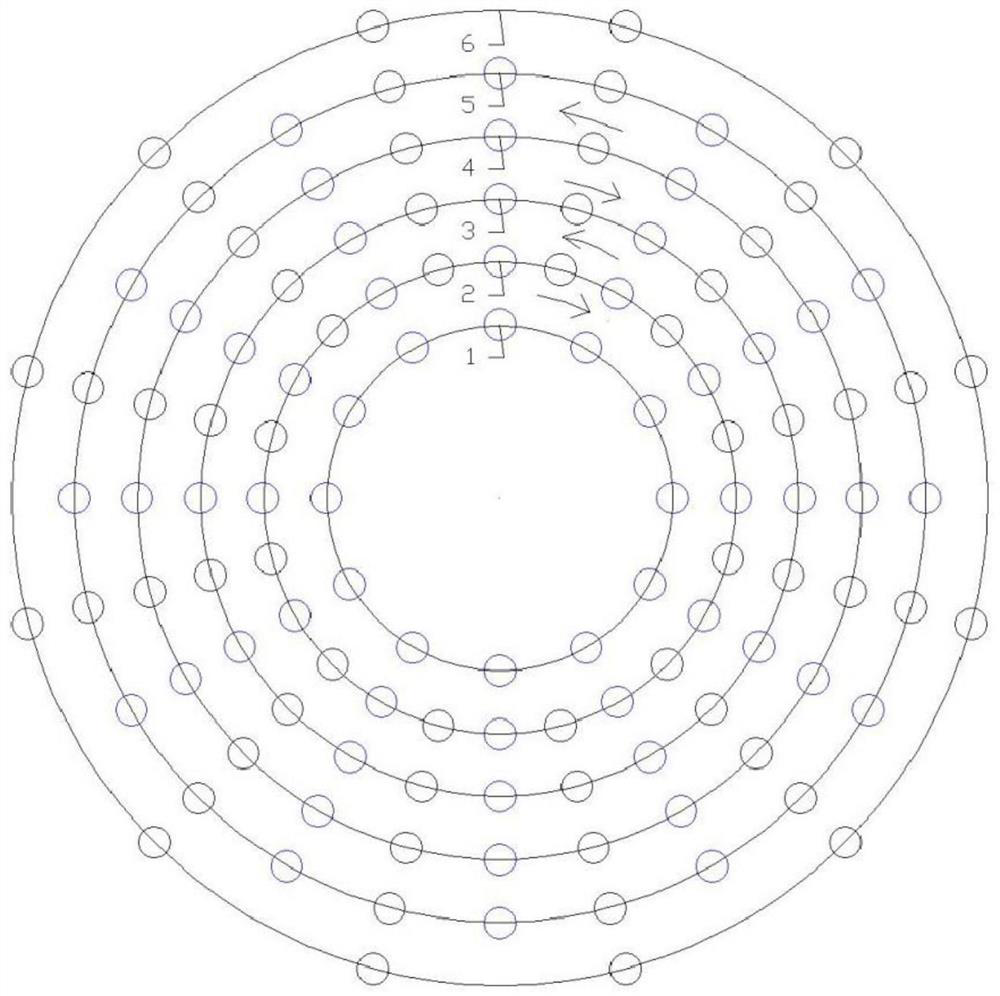

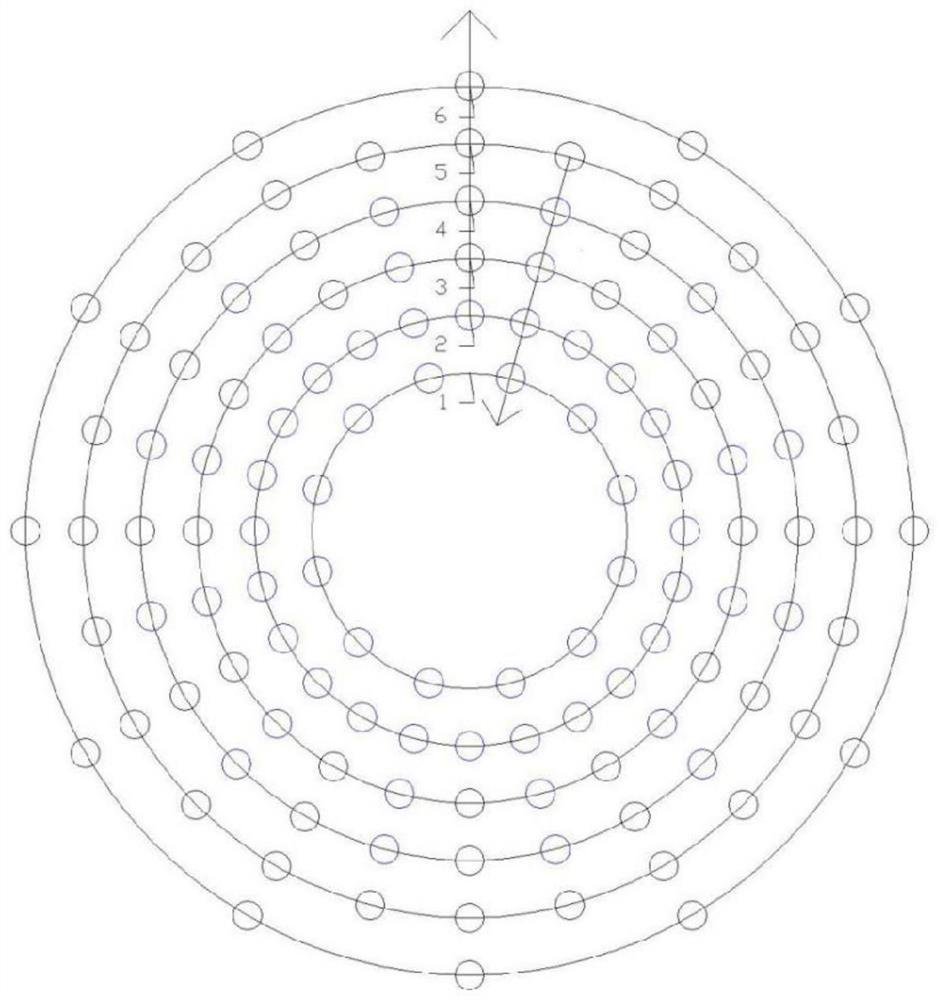

[0027] In this second embodiment, based on Figure 2-6 A knitting cycle process of knitting + three-dimensional knitting is illustrated.

[0028] figure 2 Shown is the first step of circular 3D knitting: turn 2 and 4 turns clockwise, 3 and 5 turns counterclockwise.

[0029] image 3 Shown is the second step of circular 3D knitting: Alternating radial movements of the yarn.

[0030] Figure 4 Shown is the third step of circular three-dimensional knitting: turn 2 and 4 turns counterclockwise, and turn 3 and 5 turns clockwise.

[0031] Figure 5 Shown is the fourth step of circular three-dimensional knitting: press figure 1 Add knitting yarn at the position shown, press Figure 5 The method shown starts with the first round of knitting from the gap between the 1st and 2nd rounds; then the needle exits from the needle entry position, and then knits the gaps of the 2nd and 3rd rounds and knits for a round; proceed alternately in this way until the 5th and 6th rounds Slit k...

Embodiment 3

[0034] In Embodiment 3, based on Figure 7-10 Describe the change of yarn arrangement in knitting + three-dimensional knitting. Figure 7 Shown is a 5×24 yarn arrangement, wherein 5: there are 5 radial yarns, and 24: circumferential yarns are 24 rows. Figure 8 It is to change the yarn arrangement of 5×24 into the yarn arrangement of 4×30 under the premise that the total number of yarns remains unchanged. Figure 9 It is to change the yarn arrangement of 4×30 into the yarn arrangement of 3×40. Figure 10 It is to change the yarn arrangement of 3×40 into the yarn arrangement of 2×60. Wherein, cross-transformation is required when performing transformation, and the yarn arrangement of 5×24 is changed into 4×30 yarn arrangement as an example. Divide the 5×24 yarn arrangement into 6 groups, and each group has 4 rows, then change the 5×4 yarn arrangement of each group into 4×5 yarn arrangement, and realize the 5× The 24 yarn pattern becomes a 4x30 yarn pattern.

[0035] As lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com