CoCrPt-oxide magnetic recording target, film and preparation method thereof

An oxide and magnetic recording technology, applied in the field of information storage, to achieve the effect of small and uniform grain size, small and uniform grain size, and low element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The CoCrPt-oxide target is prepared by two-way vacuum hot pressing, and the specific preparation method includes the following steps:

[0036] (1) Powder pretreatment: the original powder is ball milled and graded, the particle size of Co, Cr, Pt raw material powder is less than 5 μm, and the particle size of oxide is less than 1 μm;

[0037] (2) Powder mixing: the finely classified powder is mixed evenly by mechanical mixing;

[0038] (3) Powder filling: the uniformly mixed powder is loaded into the graphite mold through the powder filling device;

[0039] (4) Powder sintering: Send the mold with high-purity powder into a vacuum hot-pressing sintering furnace for two-way vacuum hot-pressing sintering with a vacuum degree of 10 -2 ~10 -4 Pa, the sintering temperature is 1000-1500°C, the sintering pressure is 30-60MPa, and the holding time is 1-5h.

[0040] (5) Hot isostatic pressing: the ingot needs to be processed by hot isostatic pressing at a temperature of 800-11...

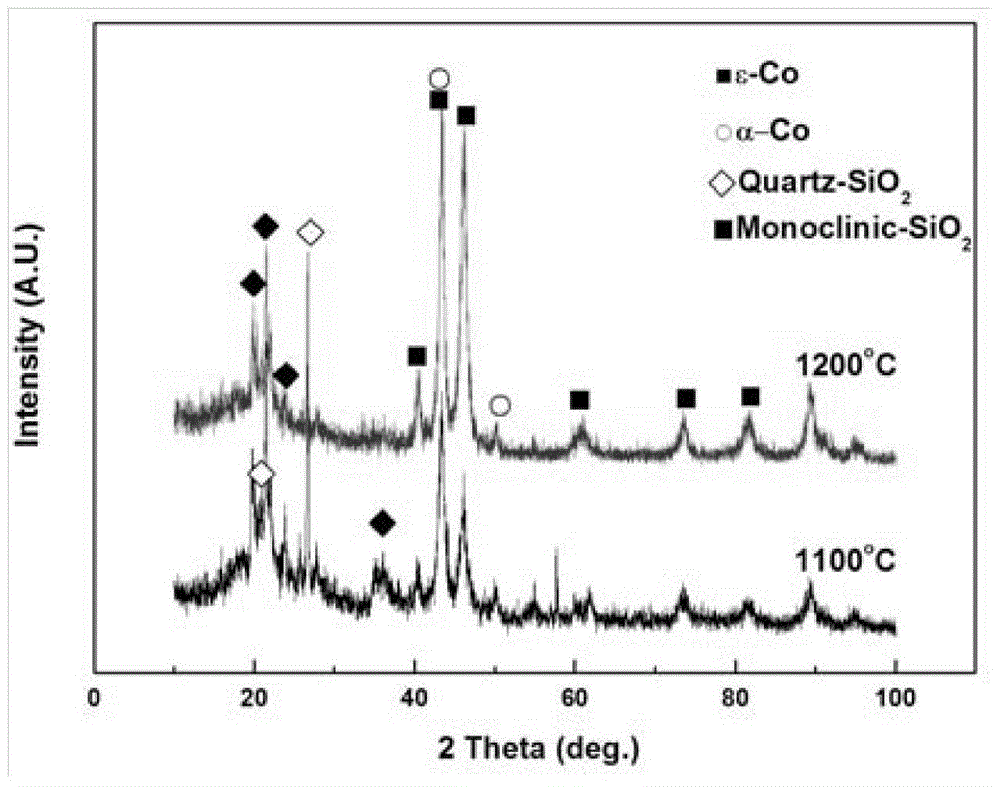

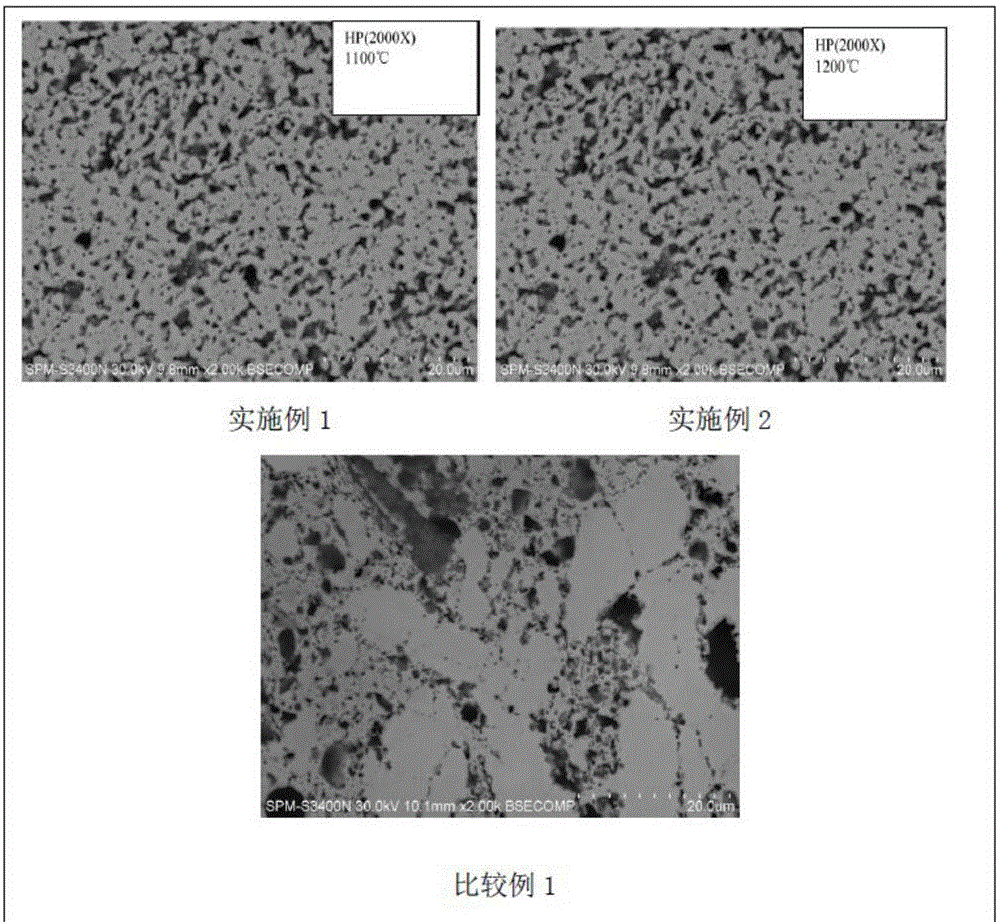

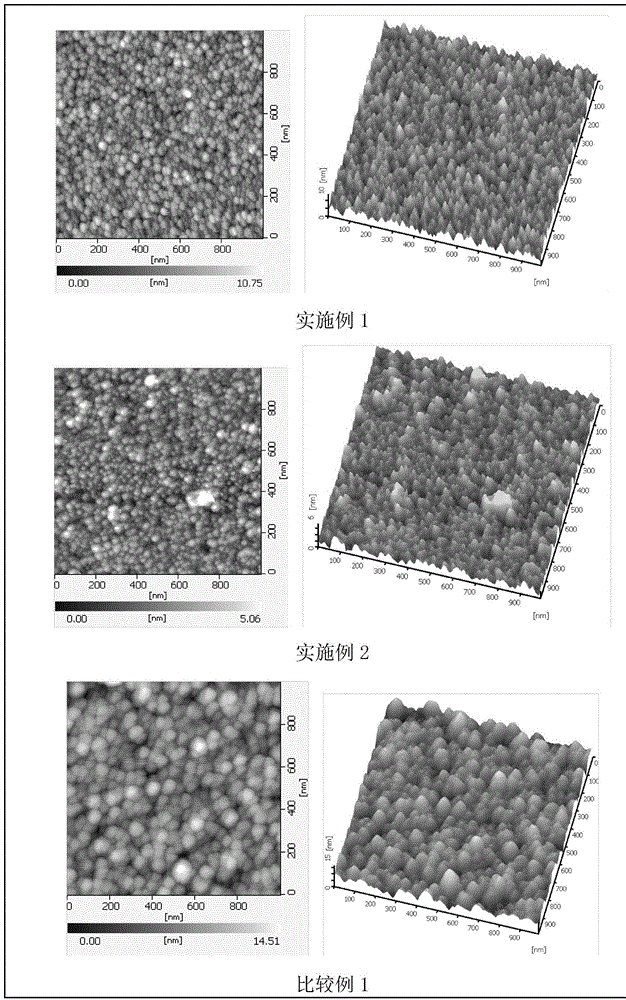

Embodiment 1

[0046] Co68Cr10Pt14-SiO of the present invention 2 The sputtering target is prepared by the following steps:

[0047] (1) Powder pretreatment: use Co, Cr, Pt and SiO above 3N5 2 As a raw material, the original powder is ball milled and classified, and the particle size of Co, Cr, and Pt raw material powders is less than 5 μm, and SiO 2 The particle size is less than 1 μm;

[0048] (2) Powder mixing: The powder after refinement and classification is based on the nominal composition Co68Cr10Pt14-SiO 2 For batching, use planetary ball mill mixing method to mix evenly;

[0049] (3) Powder filling: the uniformly mixed powder is loaded into the graphite mold through the powder loading device, and the surface of the graphite mold is sprayed with an oxide layer for treatment;

[0050] (4) Powder sintering: Send the mold with high-purity powder into a vacuum hot-pressing sintering furnace for two-way vacuum hot-pressing sintering with a vacuum degree of 10 -2 ~10 -4 Pa, the sinte...

Embodiment 2

[0055] The difference from Example 1 is that the CoCrPt-SiO 2 The alloy target is Co60Cr10Pt18-SiO 2 . The vacuum hot pressing temperature of the alloy ingot is 1200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com