A kind of honeycomb sandwich composite structure material and preparation method thereof

A composite structure and honeycomb technology, applied in the field of materials, can solve the problems of difficult to meet the needs of materials, narrow effective damping temperature range, low strength and stiffness, etc., and achieve long service life, high damping loss factor, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, the aramid paper honeycomb sandwich composite damping material filled with PMMA / [EMIM][TFSI] solution

[0055] 1. Preparation of PMMA / [EMIM][TFSI] solution

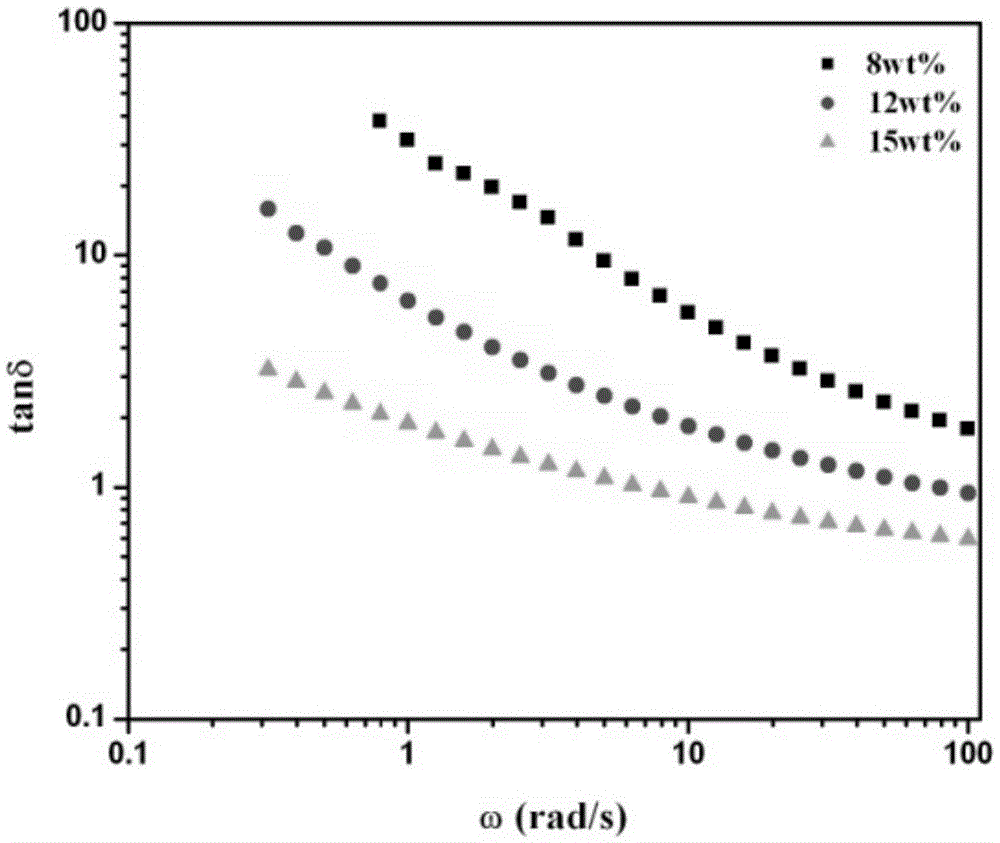

[0056] Dissolve PMMA in dichloromethane, then add [EMIM][TFSI] ionic liquid, stir evenly, let stand at room temperature, let the dichloromethane basically volatilize, then dry under reduced pressure at 70°C to constant weight . A colorless, clear and transparent viscous solution was obtained. The ionic liquid solutions with PMMA mass fractions of 8wt%, 12wt% and 15wt% were prepared respectively. The PMMA / [EMIM][TFSI] solutions of different mass fractions were used for dynamic shear tests, and the results were as follows: figure 2 As shown, it can be seen that the PMMA / [EMIM][TFSI] solution exhibits a high damping loss factor.

[0057] 2. Preparation of honeycomb materials filled with ionic liquid polymers

[0058] Coat a layer of uncured DowCorning186 liquid silicone rubber on a flat PTFE board,...

Embodiment 2

[0062] Embodiment 2, aramid paper honeycomb sandwich composite damping material filled with liquid polyisobutylene (PIB)

[0063] According to the steps of Example 1, only the 8wt% PMMA / [EMIM][TFSI] solution was replaced with liquid polyisobutylene (PIB), and the composite damping material with a sandwich sandwich structure provided by the present invention was obtained.

[0064] The honeycomb sandwich composite structure material is composed of a honeycomb matrix material, a filling material and a sealing layer; wherein, the filling material liquid polyisobutylene (PIB) is embedded in the honeycomb matrix material; the sealing layer silicone rubber film is located on the upper and lower surfaces of the honeycomb matrix material .

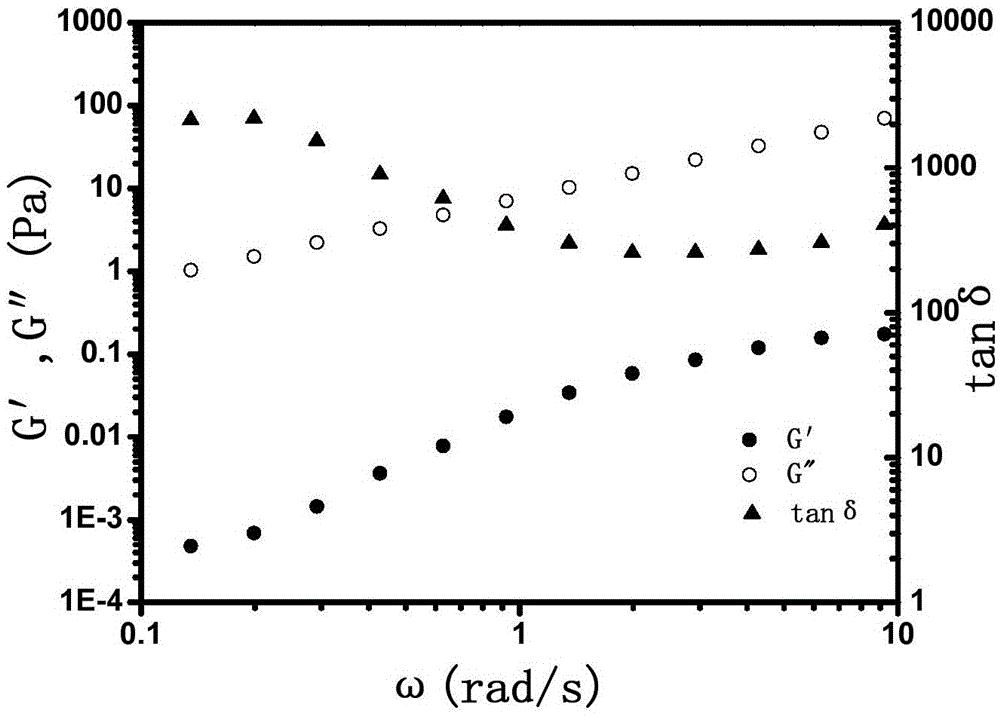

[0065] image 3 Be storage modulus G ' of PIB in this embodiment, loss modulus G " and loss factor tan δ change curve (25 ℃) with angular frequency ω. As can be seen from the figure, PIB is in the frequency range 0.1-10rad / s of test All have high...

Embodiment 3

[0066] Embodiment 3, aramid paper honeycomb sandwich composite damping material filled with liquid polybutadiene (PB)

[0067] In this example, liquid PB was selected as the filling material to prepare the honeycomb sandwich composite structure.

[0068] Do a dynamic shear test on PB, the results are as follows Figure 4 As shown, it can be seen that the liquid PB has a high damping loss factor in the whole frequency range.

[0069] Coat a layer of uncured DowCorning186 liquid silicone rubber on a flat PTFE board, gently place the cut aramid paper honeycomb core on it, and cure at 60°C for 3 hours, the lower part of the honeycomb core is glued by the silicone rubber film Then seal.

[0070] Use a syringe to fill the PB into the holes of the honeycomb, vacuumize for 0.5h, until the vacuum degree is 200mbar, after completely eliminating the air bubbles inside, mix with 4%wt crosslinking agent trimethylolpropane tris(3-mercaptopropane) Ester) PB solution coated on the upper pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com