A plasticizing machine for the production of halogen-free cross-linking lines

A technology of cross-linking line and plasticizing machine is applied in the mechanical field of motor connecting line production and processing, which can solve the problems of inability to meet modern industrial production and low heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

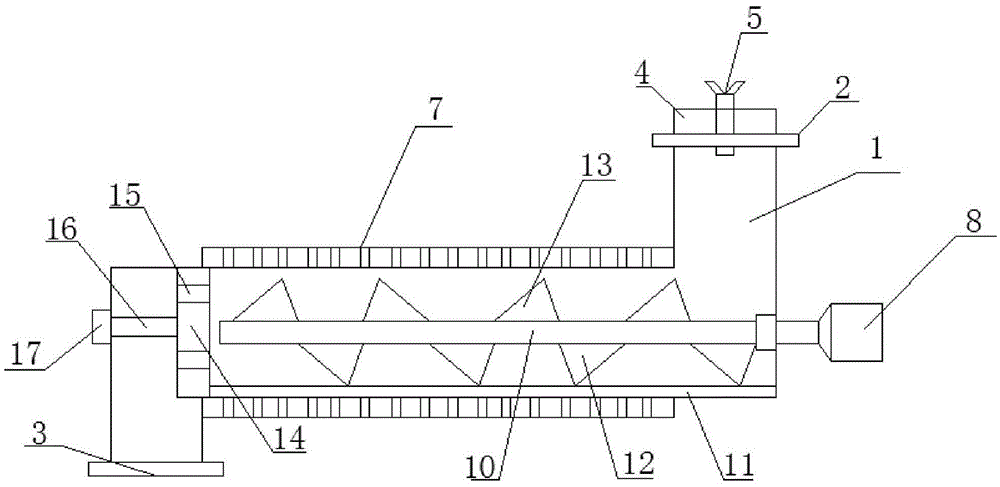

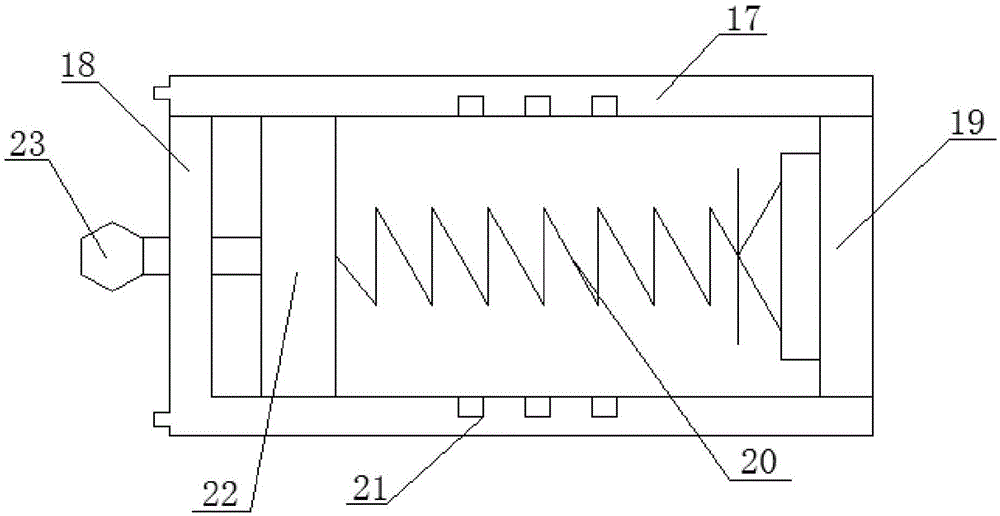

[0015] Such as figure 1 A plasticizing machine for the production of halogen-free cross-linking line shown in , includes a plasticizing machine body 1, the upper and lower sides of the plasticizing machine body 1 are respectively provided with a material inlet 2 and a material outlet 3, and the plasticizing machine body 1 The outer ring is provided with a coil 7, and the screw stirring and conveying device is connected inside the plasticizing body 1. A pneumatic cylinder 17 is provided on the side wall of the plasticizing body 1. The pneumatic cylinder 17 is connected with the piston 14 through the piston rod 16, and the piston 14 is slidingly connected. In the plasticizing body 1 , a pressure protection device 15 is provided on the piston 14 , the sealing end cap 4 is connected above the feeding port 2 , and the pressure valve 5 is connected inside the plasticizing body 1 through the sealing end cap 4 . When working, pour a sufficient amount of insulating material into the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com