Rotating motor controls and electric power steering equipment

A technology for rotating electrical machines and control devices, applied in motor control, power steering mechanism, electric steering mechanism, etc., can solve the problems of error margin, excessive power supply current, insufficient output of rotating electrical machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

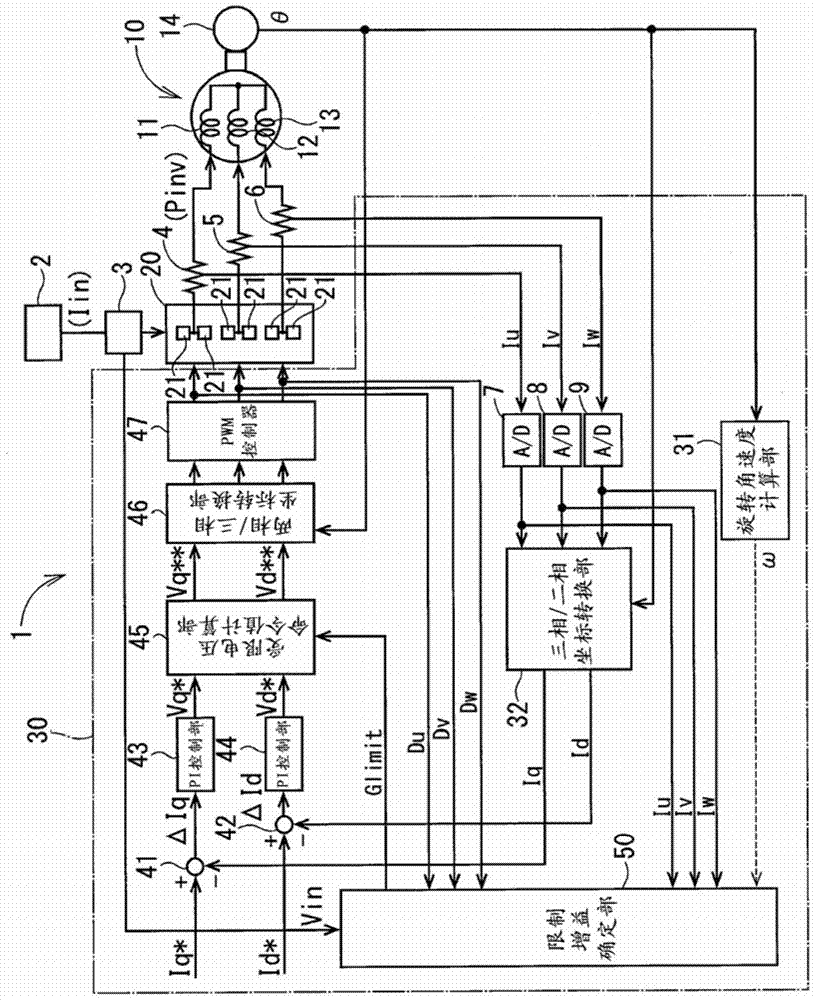

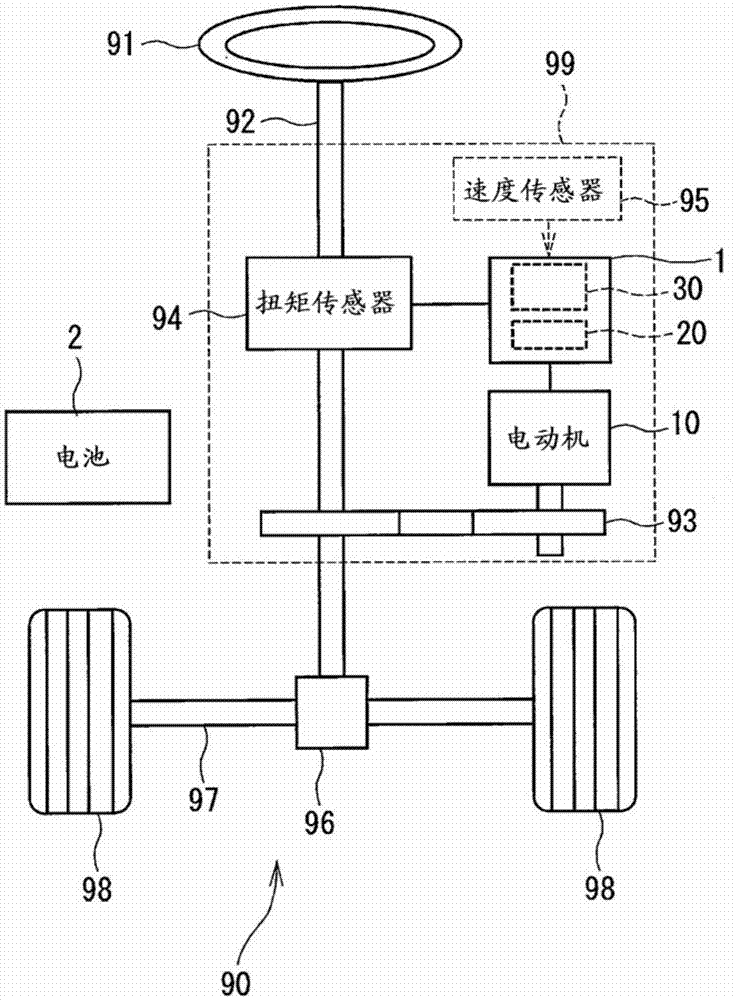

[0020] will refer to figure 1 The rotating electric machine control device 1 according to the first embodiment of the present disclosure will be described. The rotary electric machine control device 1 controls the driving of an electric motor 10 as a rotary electric machine. The rotary electric machine control device 1 can be used, for example, in an electric power steering apparatus that assists a steering operation of a vehicle.

[0021] figure 2 is a diagram showing a steering system 90 including an electric power steering device 99 . The electric power steering device 99 includes a torque sensor 94 . A torque sensor 94 is attached to a steering shaft 92 connected to a steering wheel 91 . The torque sensor 94 detects the steering torque input by the driver to the steering shaft 92 via the steering wheel 91 .

[0022] Attached to one end of the steering shaft 92 is a pinion gear 96 . The pinion gear 96 meshes with the rack shaft 97 . At the end of the rack shaft 97,...

no. 2 approach

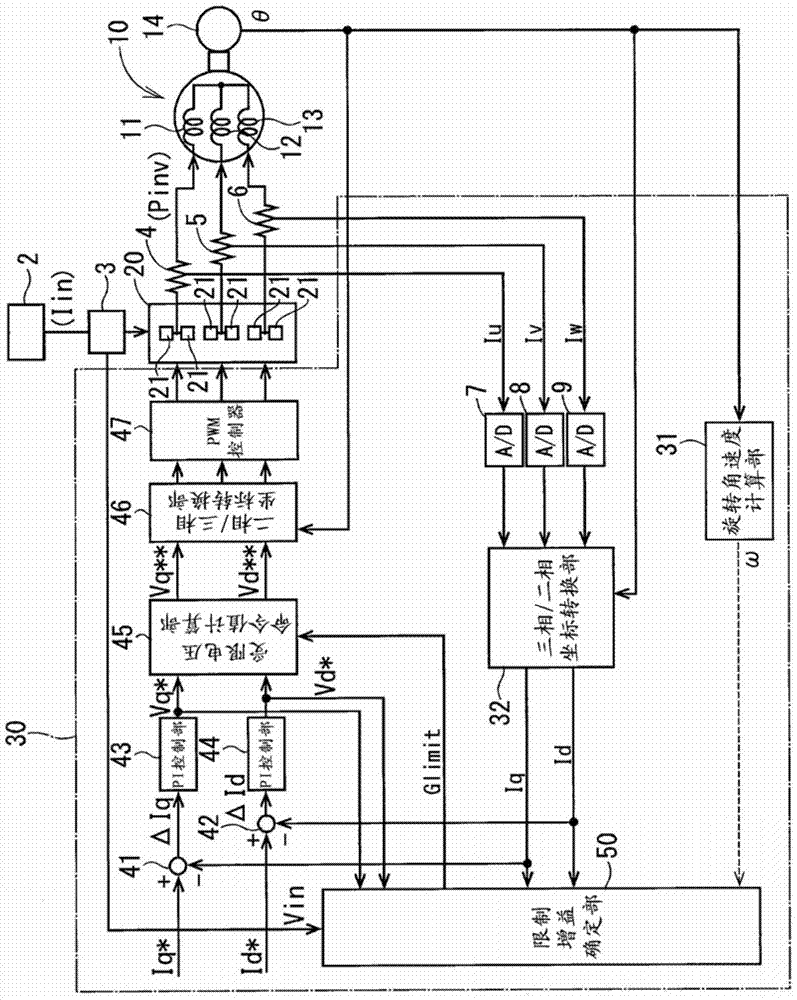

[0060] will refer to image 3 A rotating electric machine control device according to a second embodiment of the present disclosure will be described. The rotating electric machine control device according to the present embodiment has a physical configuration similar to that of the rotating electric machine control device according to the first embodiment. However, the limit gain determination section 50 according to the present embodiment determines the limit gain Glimit in a manner different from that of the first embodiment.

[0061] In the present embodiment, the limit gain determination section 50 determines the limit gain Glimit through a series of first to fourth steps described below. In the present embodiment as well, the limit gain determination section 50 repeats the series of first to fourth steps at a predetermined cycle and determines the limit gain Glimit each time.

[0062] In the first step, the limit gain determination section 50 is based on the U-phase cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com