Packaging structure for integrating VCO and waveguide antenna

A packaging structure, waveguide antenna technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of restricting PCB circuit design and application, difficult to achieve impedance matching, increase design investment, etc., to achieve convenient Large-scale production and application, easy miniaturization design, and the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

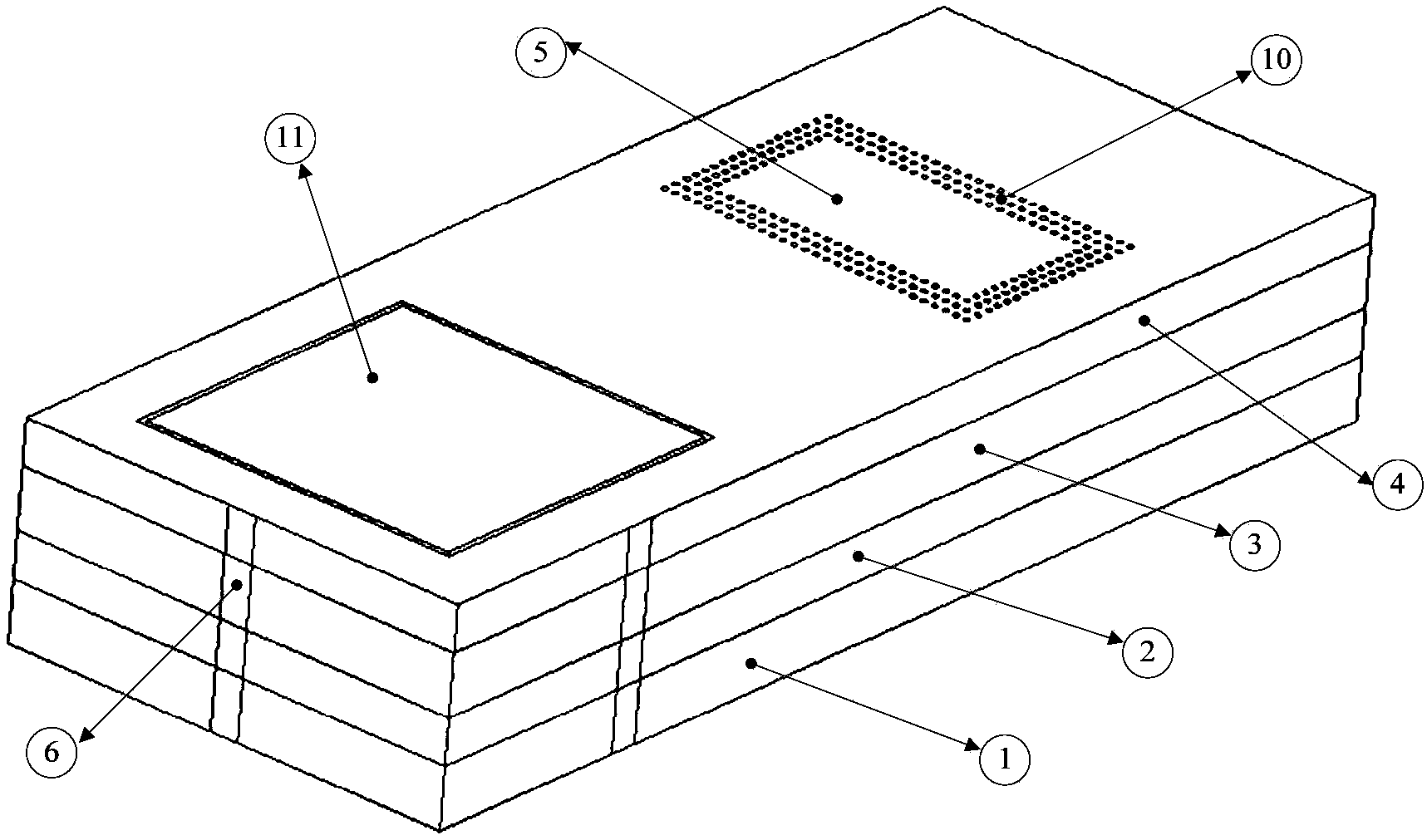

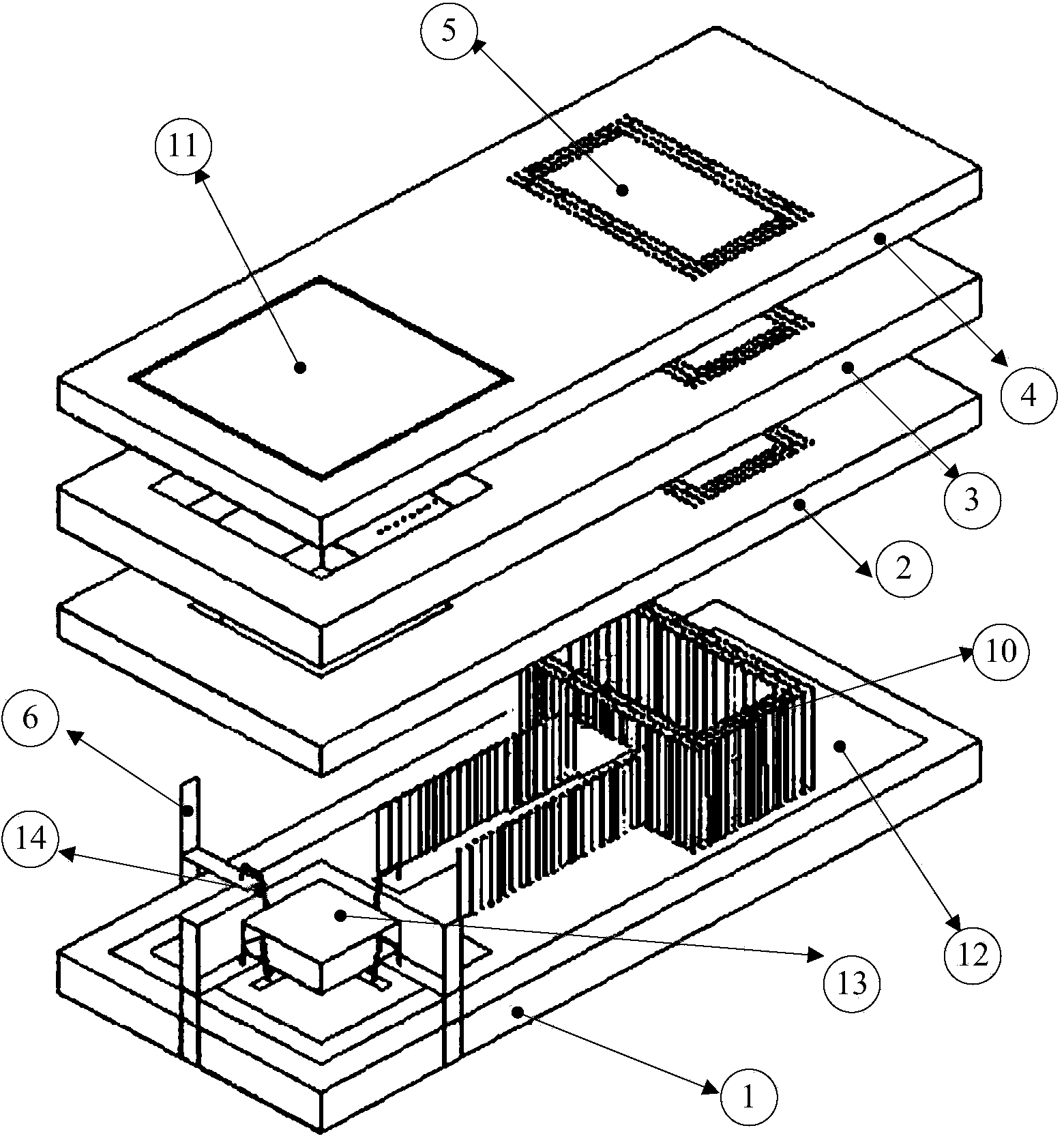

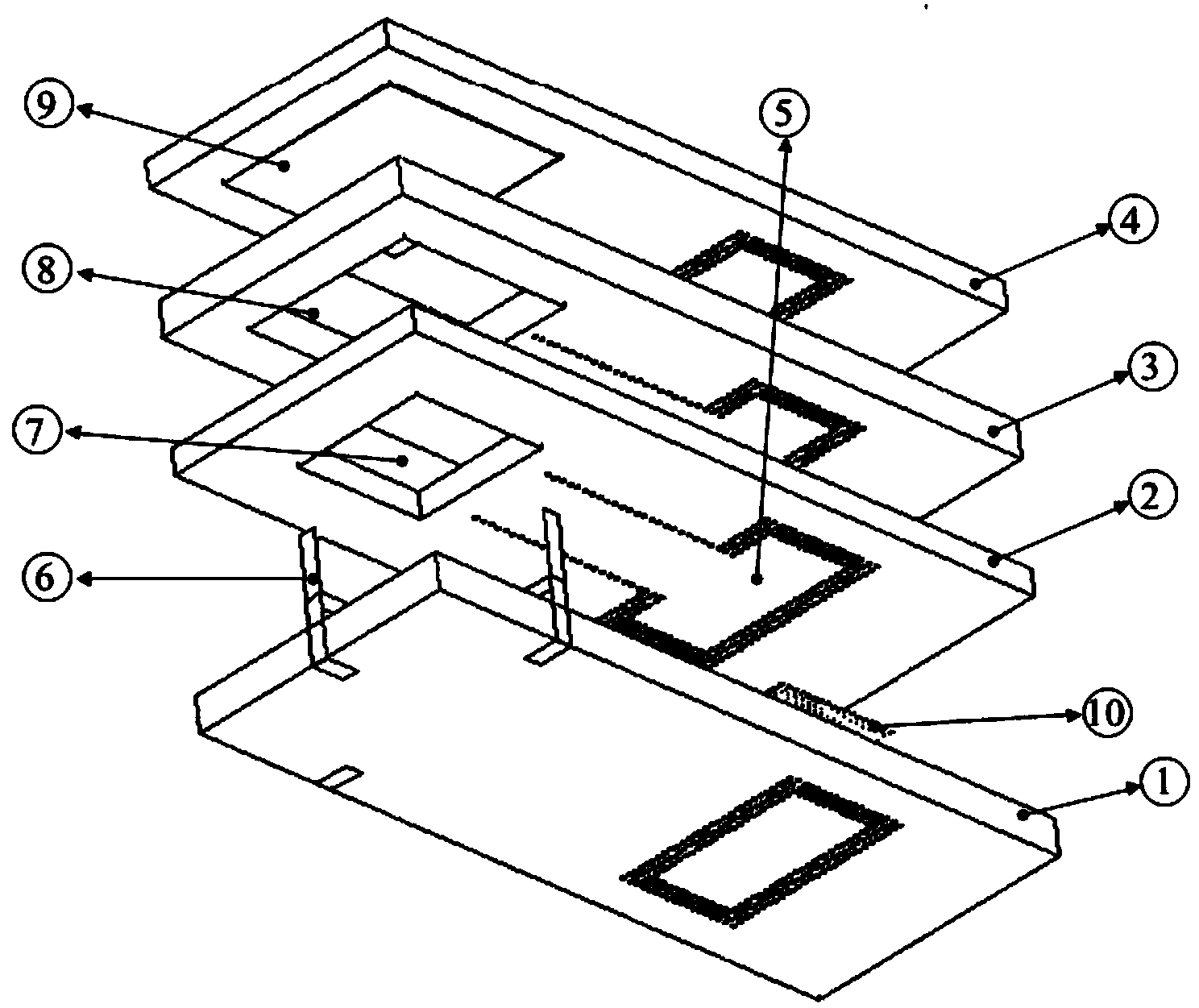

[0037] see Figure 1 ~ Figure 4 , a packaging structure integrating a VCO and a waveguide antenna, including an LTCC package composed of a bottom dielectric substrate layer, several intermediate dielectric substrate layers, and a top dielectric substrate layer. One end of the LTCC package is packaged with a VCO chip, and the other end is packaged with a waveguide reflection cavity. and microstrip coupled probes;

[0038] The VCO chip is arranged at one end of the bottom dielectric substrate layer, and the other end of the dielectric substrate layer is provided with a through hole matching the VCO chip, and the top dielectric substrate layer is also provided with a metal cover for sealing the through hole. The substrate layer is provided with a GND metal grid reflective surface that provides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com