Permanent electromagnetic radiation resistant fabric

An electromagnetic radiation protection and permanent technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of reduced shielding effect, reduced electromagnetic radiation shielding performance and service life, etc., achieving CIE value with little impact, good dyeing effect, The effect of clothing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, the preparation of nano metal particles

[0025] 1) Dissolve silver nitrate, copper nitrate, and PVPK-30 in deionized water at high temperature, and prepare solutions with concentrations of 1.6mmol / mL, 0.8mmol / mL, and 3.2mmol / mL, respectively, and stir at 400 rpm. The three solutions are mixed uniformly to obtain a mixed solution, and the mol ratio of silver nitrate, copper nitrate and PVPK-30 in the mixed solution is 2:1:4;

[0026] 2) According to the ratio of silver nitrate, copper nitrate and hydrazine hydrate molar ratio of 2:1:5, it is configured into an aqueous solution of hydrazine hydrate with a concentration of 3.6mmol / mL, stirred at 400 rpm, and the mixed liquid obtained in step 1) is mixed into droplets Add it to the aqueous solution of hydrazine hydrate, adjust the pH value to 6.7 with ammonia water, react at 65°C for 1.5h, then separate, wash, and dry at 50°C to obtain nanometer metal particles.

Embodiment 2

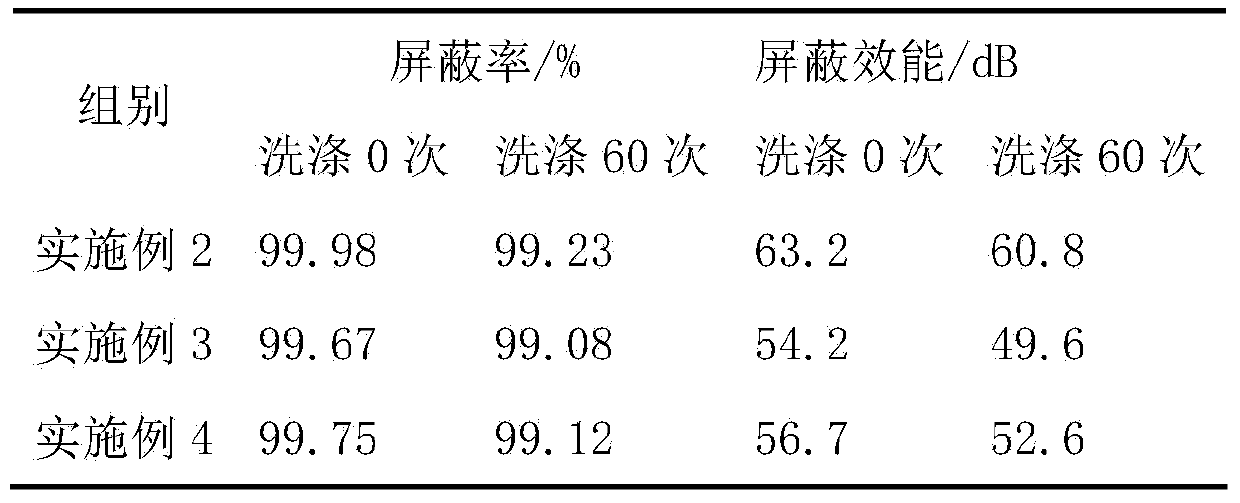

[0027] Embodiment 2, the preparation of permanent anti-electromagnetic radiation fabric

[0028] The anti-electromagnetic radiation coating is composed of the following raw materials in weight percentage: 5.2% polyvinyl alcohol, 2.1% polyvinyl acetate emulsion, 30% nano metal particles prepared in Example 1, and the balance is water.

[0029] According to the above formula, mix the raw materials and put them into the mixing heating pot to heat, make the temperature of each raw material reach 75 ℃, stir into a slurry; then pour the slurry into the grinder for 15 minutes, filter 200 mesh The finished anti-electromagnetic radiation coating is obtained by sieving, and coated on the surface of flexible fiber fabrics, the thickness is controlled at 150 μm, pre-baked at 110°C for 2 minutes, cured at 130°C for 12 minutes, and placed for 24 hours.

Embodiment 3

[0030] Embodiment 3, the preparation of permanent anti-electromagnetic radiation fabric

[0031] The anti-electromagnetic radiation coating is composed of the following raw materials in weight percentage: 1% polyvinyl alcohol, 0.1% polyvinyl acetate emulsion, 15% nano metal particles prepared in Example 1, and the balance is water.

[0032]According to the above formula, mix the raw materials and put them into the mixing heating pot to heat, make the temperature of each raw material reach 75 ℃, stir into a slurry; then pour the slurry into the grinder for 15 minutes, filter 200 mesh The finished anti-electromagnetic radiation coating is obtained by sieving, and coated on the surface of flexible fiber fabrics, the thickness is controlled at 150 μm, pre-baked at 110°C for 2 minutes, cured at 130°C for 12 minutes, and placed for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com