Rare-earth-free low-cost high-strength heat-conducting magnesium alloy and preparation method thereof

A magnesium alloy, low-cost technology, applied in the field of metal materials and metal material processing, can solve the problems of reduced thermal conductivity, low cost density, and high alloy density, and achieve high thermal conductivity and strength, low alloy cost, and low alloy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

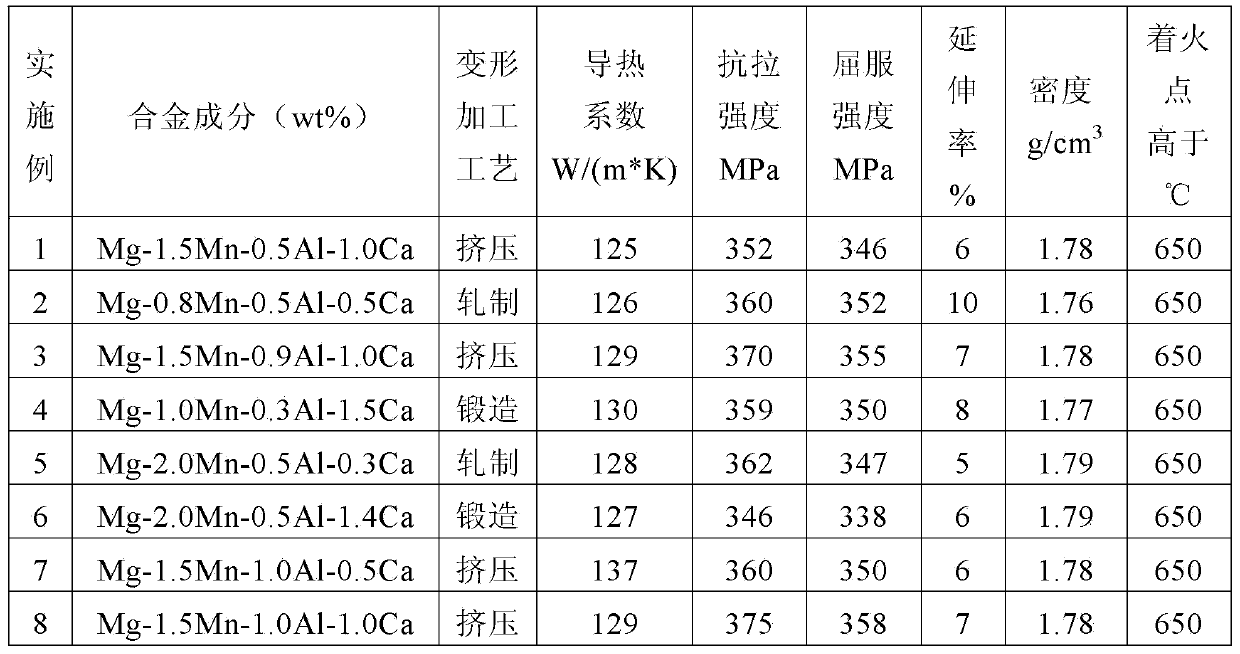

[0048] The design selects the Mg-1.5Mn-0.5Al-1.0Ca (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method of its rare earth-free low-cost high-strength heat-conducting magnesium alloy is as follows:

[0049] 1) With pure Mg ingot, pure Al ingot, pure Ca particles and Mg-5Mn master alloy (that is, the composition content of the master alloy is: 5wt% Mn, the rest is Mg) raw materials, according to the weight percentage of the above-mentioned magnesium alloy composition Ingredients;

[0050] 2) After the crucible is cleaned and preheated, put all the pure magnesium ingots and the Mg-5Mn master alloy into the crucible of the smelting furnace. 2 and SF 6 Heating under the protection of mixed protective gas, the heating rate is 20 ~ 40 ℃ / min, CO 2 and SF 6 The flow ratio is 50, and the temperature of the melt after complete melting is controlled at 710-760°C;

[0051] 3) Heat the pure Al ingot in a preheating furnace to 250-310°C, add the preheated...

Embodiment 2

[0055] The design selects Mg-0.8Mn-0.5Al-0.5Ca (wt%) chemical composition ratio to form a magnesium alloy, and the preparation method of its rare earth-free low-cost high-strength heat-conducting magnesium alloy material is as follows:

[0056] 1) With pure Mg ingot, pure Al ingot, Mg-30Ca and Mg-5Mn master alloy as raw material, carry out batching according to the weight percentage of above-mentioned magnesium alloy composition;

[0057] 2) After the crucible is cleaned and preheated, put all the pure magnesium ingots and the Mg-5Mn master alloy into the crucible of the smelting furnace. 2 and SF 6 Heating under the protection of mixed protective gas, the heating rate is 20 ~ 40 ℃ / min, CO 2 and SF 6 The flow ratio is 50, and the temperature of the melt after complete melting is controlled at 710-760°C;

[0058] 3) Put the pure Al ingot in the preheating furnace and heat it to 250-310°C, add the preheated Al ingot and the Mg-Ca master alloy into the magnesium melt success...

Embodiment 3

[0062] The design selects the Mg-1.5Mn-0.9Al-1.0Ca (wt%) alloy composition ratio to form a thermally conductive magnesium alloy, and the extrusion profile preparation method is as follows:

[0063] 1) Proportioning alloy raw materials and smelting and pouring into ingot according to the method described in embodiment 1;

[0064]2) Cut the heat-conducting magnesium alloy ingot prepared above directly into corresponding extrusion billets, and then directly adopt the extrusion process to deform the billets into forming materials after preheating at 350°C. The extrusion speed is 3m / min, and the extrusion ratio 25, the extruded material is cooled by air cooling, that is, a rare earth-free, low-cost, high-strength, heat-conducting magnesium alloy can be obtained.

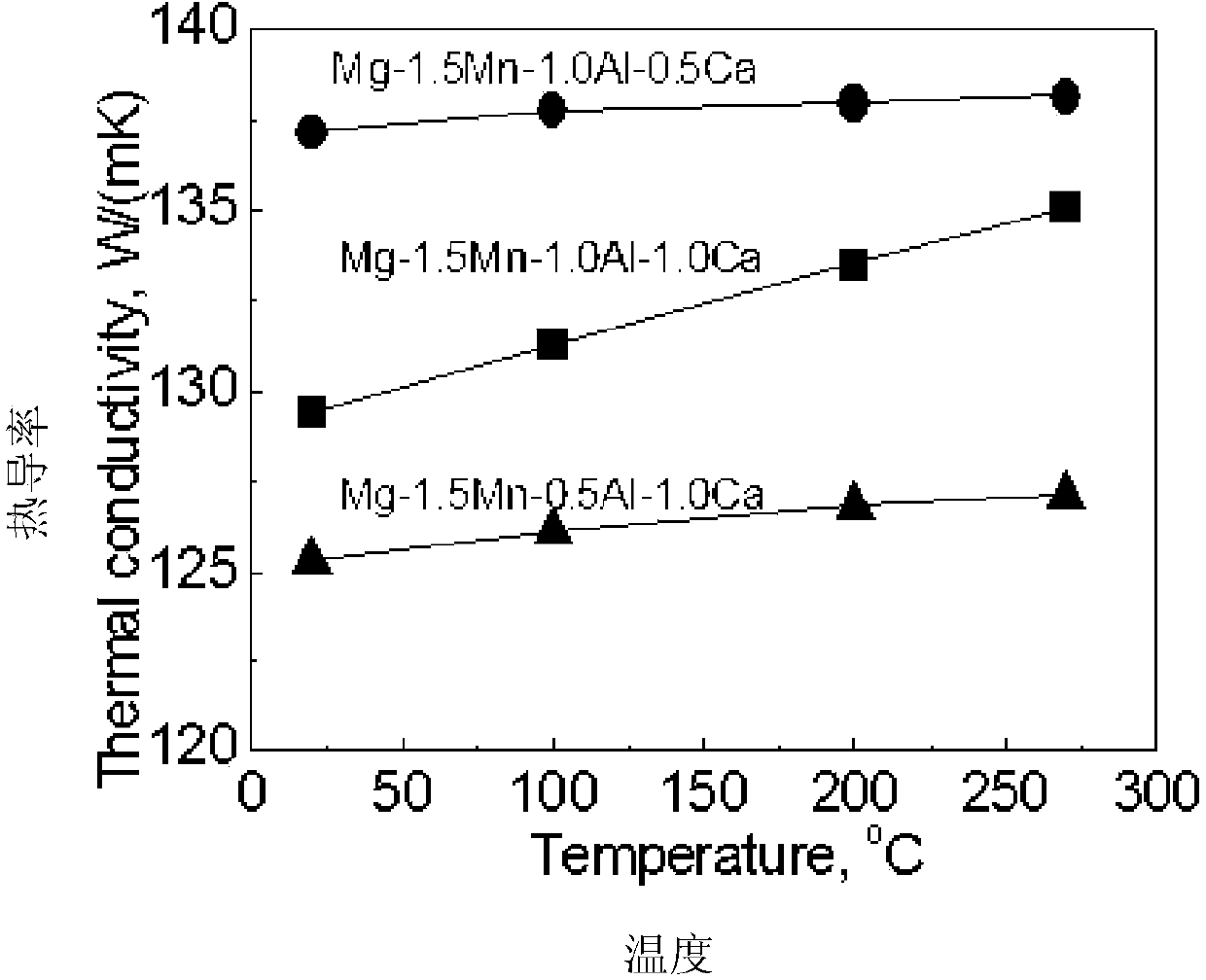

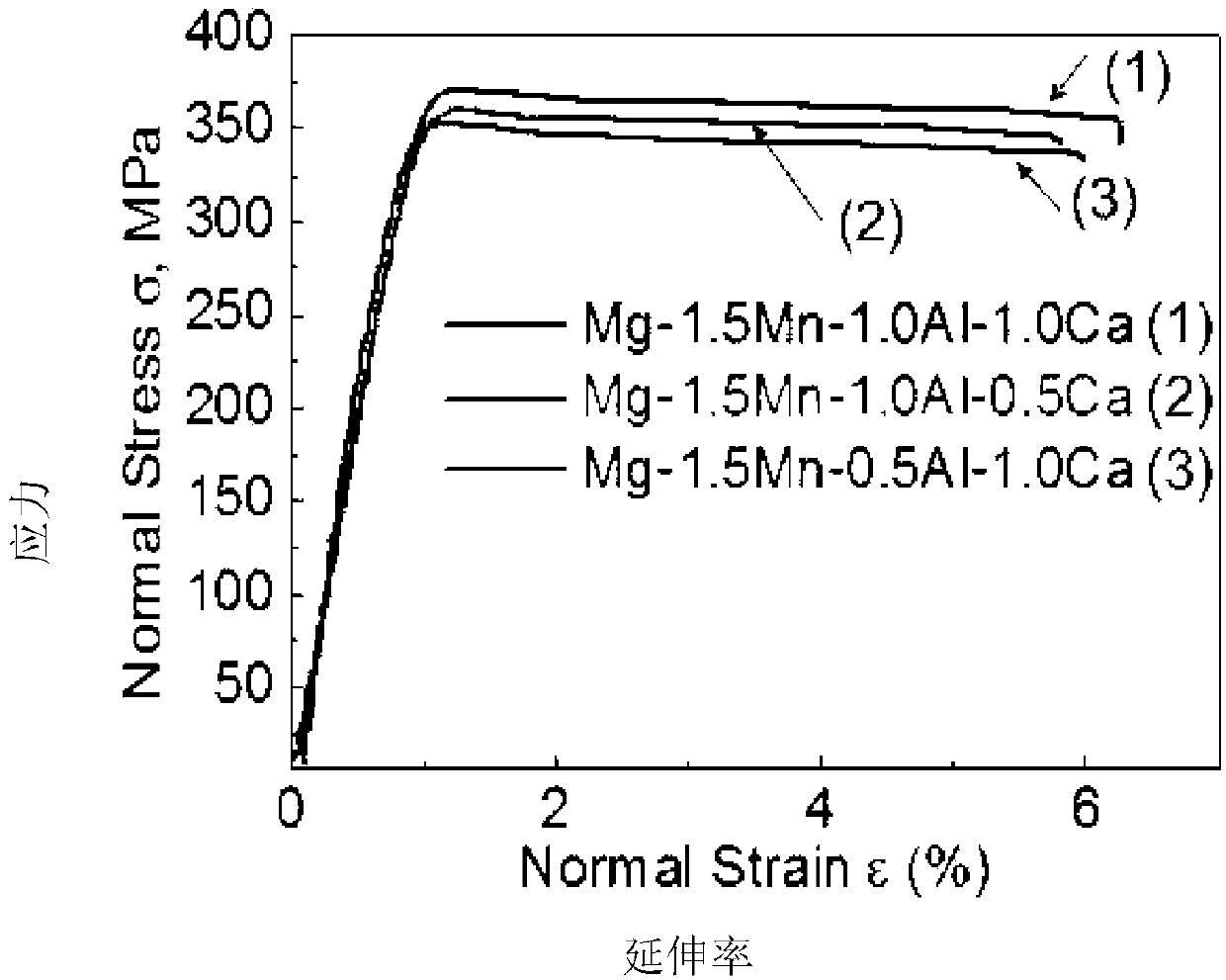

[0065] The prepared rare earth-free low-cost high-strength thermally conductive magnesium alloy has a thermal conductivity of 129W / (m*K) at 20°C, a room temperature (25°C) tensile strength of 370MPa, a tensile yield stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com