Liquid crystal thin film and preparation method thereof, temperature response apparatus and circular polarizer

A technology of liquid crystal film and cholesteric liquid crystal, which is applied to liquid crystal materials, polarizing elements, chemical instruments and methods, etc., can solve the problems of optical performance influence, difficult process control, difficult electrode processing, etc., and achieves low cost and simple preparation process. , the effect of a wide reflection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

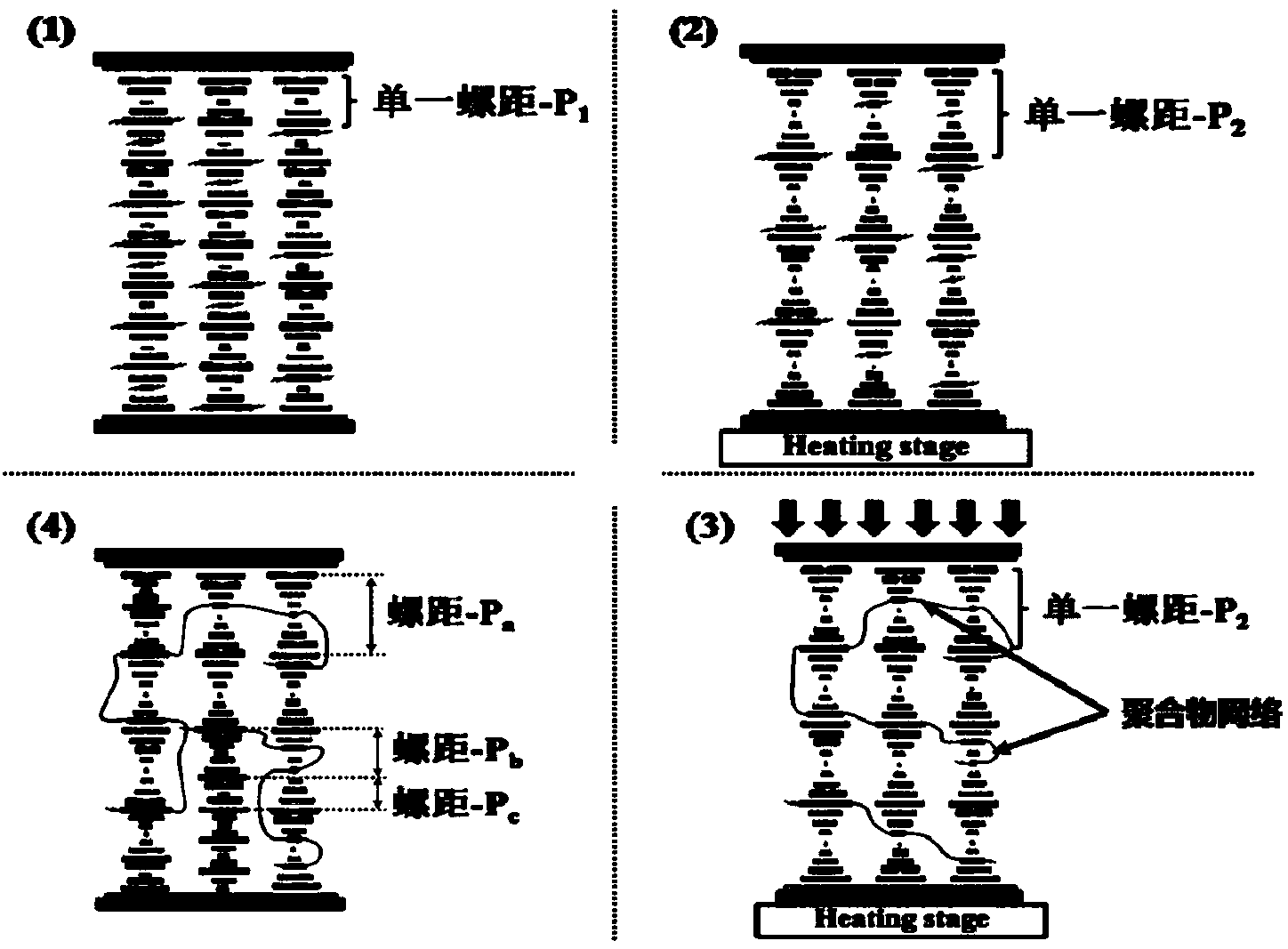

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of liquid crystal film with broadband reflection characteristics at room temperature

[0040] 1) Preparation of cholesteric liquid crystal: chiral liquid crystal polymerizable monomer Ch1 (0.0632g), small molecule nematic liquid crystal SLC1717 (0.1174g), chiral additive 5CBB (0.0296g), chiral additive ZLI- 4572 (0.012g) and photoinitiator Irg651 (Irgacure651) (0.001g) were thoroughly mixed and prepared by solvent evaporation method;

[0041] 2) Adding hydrogen bond acceptor CBS (0.01442g) and hydrogen bond donor CHG (0.02558g) to the cholesteric liquid crystal obtained in step 1) to form a complex system, which has a P1 pitch at room temperature;

[0042] Step 1), step 2) described components are as follows:

[0043]

[0044] 3) Perform variable temperature infrared tests on the composite system, such as figure 2 As shown, the hydrogen bond breaking temperature in the composite system is determined to be 220°C (T1); the composite system is t...

Embodiment 2

[0048] Example 2 Preparation of liquid crystal film with broadband reflection characteristics at room temperature

[0049] According to the method of Example 1, a liquid crystal film with broadband reflection characteristics at room temperature was prepared. The difference is that in step 1), the cholesteric liquid crystal is prepared from the following components: chiral liquid crystal polymerizable monomer Ch1 (0.0562g), small molecule nematic liquid crystal SLC1717 (0.1286g), chiral additive CB15 ( 0.005g), chiral additive ZLI-4571 (0.007g) and photoinitiator Irg651 (0.0015g).

[0050] In step 2), hydrogen bond acceptor CBS (0.01084g) and hydrogen bond donor YXG (0.00916g).

[0051] In step 3), the hydrogen bond breaking temperature is 200°C;

[0052] In step 4), the irradiation intensity is 365nm, 2mW / cm 2 ; The irradiation time is 25 minutes; the temperature of the liquid crystal cell is lowered to room temperature to obtain a liquid crystal film with a reflection wave...

Embodiment 3

[0053] Example 3 Preparation of liquid crystal film with broadband reflection characteristics at room temperature

[0054] According to the method of Example 1, a liquid crystal film with broadband reflection characteristics at room temperature was prepared. The difference is that in step 1), the cholesteric liquid crystal is prepared from the following components: chiral liquid crystal polymerizable monomer Ch1 (0.0362g), small molecule nematic liquid crystal SLC1717 (0.0592g), chiral additive 5CBB ( 0.0148g), chiral additive ZLI-4572 (0.006g) and photoinitiator Irg651 (0.0015g).

[0055] In step 2), hydrogen bond acceptor BTS (0.007874g) and hydrogen bond donor YXG (0.012126g).

[0056] In step 3), the hydrogen bond breaking temperature is 240°C;

[0057] In step 4), the irradiation intensity is 365nm, 3.3mW / cm 2 ; The irradiation time is 18 minutes; the temperature of the liquid crystal cell is lowered to room temperature to obtain a liquid crystal film with a reflection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com