A kind of preparation method of flexible ultra-thin glass

An ultra-thin glass and flexible technology, applied in glass manufacturing equipment, glass molding, glass production, etc., can solve problems that affect product processing performance, micro-waviness warping, point defects, etc., and achieve strong application potential, The effect of strong flexibility and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

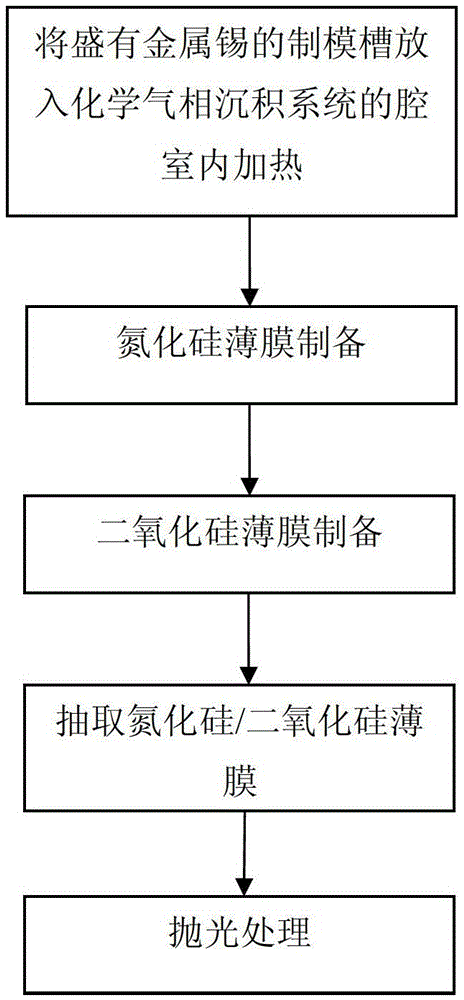

[0036] according to figure 1 The process flow of the chemical vapor deposition technology shown in the preparation of ultra-thin glass, the specific steps are as follows:

[0037] 1. Put the tin nugget into the molding slot.

[0038] 2. Put the molding tank into the reaction chamber of the chemical vapor deposition system, and adjust the temperature of the chamber to 300°C;

[0039] 3. Turn on the mechanical pump in turn to pump the low vacuum of the reaction chamber to about 1Pa;

[0040] 4. Introduce argon gas, the flow rate is 45sccm, adjust the chamber pressure to 30Pa; turn on the radio frequency power supply, set the radio frequency power to 200W;

[0041] 5. Introduce ammonia gas with a flow rate of 40 sccm; after the pressure stabilizes, inject silane with a total flow rate of 20 sccm; finally readjust the reaction pressure to 30 Pa;

[0042] 6. Control the growth time for 60 minutes to prepare silicon nitride film;

[0043] 7. Stop feeding ammonia gas.

[0044] 8...

Embodiment 2

[0051] according to figure 1 The process flow of the chemical vapor deposition technology shown in the preparation of ultra-thin glass, the specific steps are as follows:

[0052] 1. Put the tin nugget into the molding slot.

[0053] 2. Put the molding tank into the reaction chamber of the chemical vapor deposition system, and adjust the temperature of the chamber to 500°C;

[0054] 3. Turn on the mechanical pump in turn to pump the low vacuum of the reaction chamber to about 1Pa;

[0055] 4. Introduce argon gas, the flow rate is 45sccm, adjust the chamber pressure to 200Pa; turn on the radio frequency power supply, set the radio frequency power to 200W;

[0056] 5. Introduce ammonia gas with a flow rate of 40 sccm; after the pressure stabilizes, inject silane with a total flow rate of 20 sccm; finally readjust the reaction pressure to 200 Pa;

[0057] 6. Control the growth time for 120 minutes to prepare silicon nitride film;

[0058] 7. Stop feeding ammonia gas.

[0059...

Embodiment 3

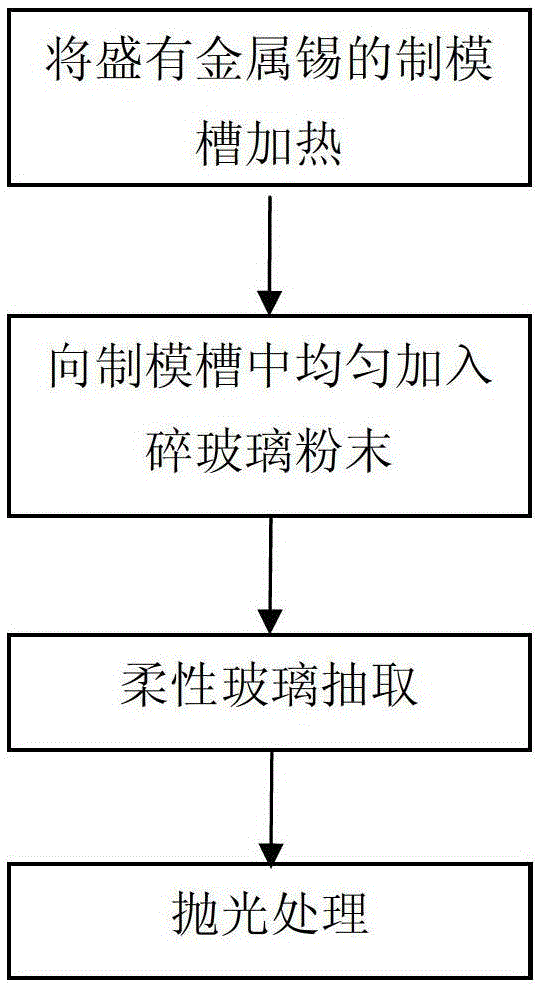

[0066] according to figure 2 The shown cullet fusing method process is used to prepare ultra-thin glass, and the specific steps are as follows:

[0067] 1. Put the tin block into the molding tank and heat the molding tank to 950°C.

[0068] 2. Sprinkle the broken glass powder with a particle size of 10μm evenly on the surface of the molten tin and melt it immediately.

[0069] 3. Cool the temperature of the molding tank and control it at 280°C.

[0070] 4. Remove the glass after the molten glass on the surface solidifies.

[0071] 5. Use a polishing machine for polishing.

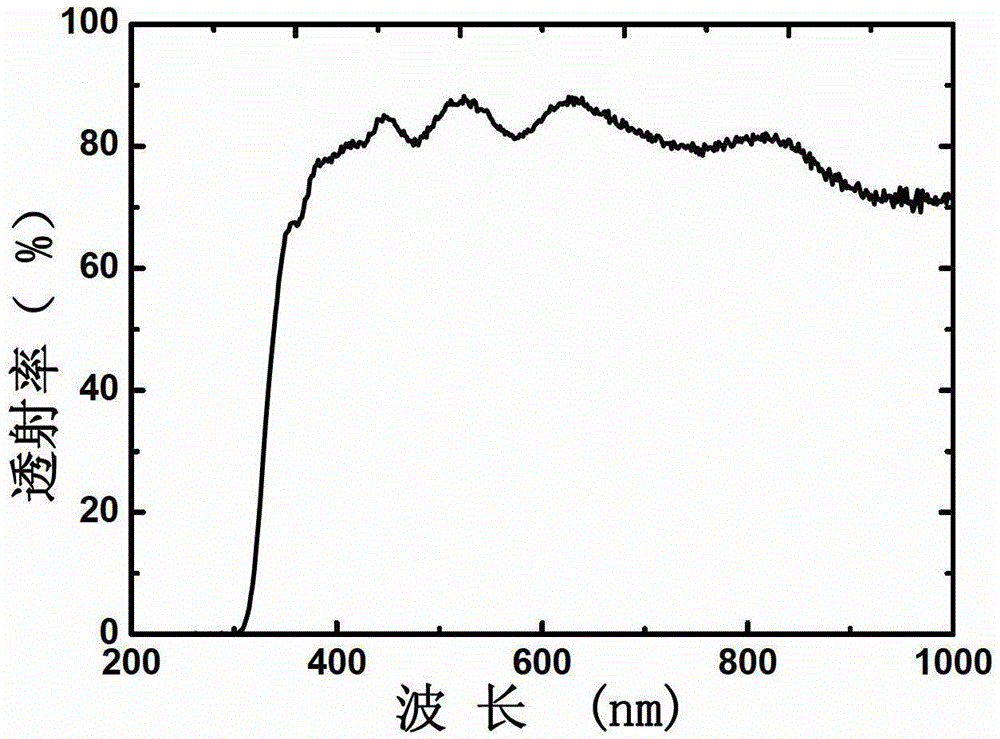

[0072] The SEM image of the flexible ultra-thin glass obtained through the above process and the graph of the variation of transmittance with wavelength are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com