Hot stamp molded article and method for producing same

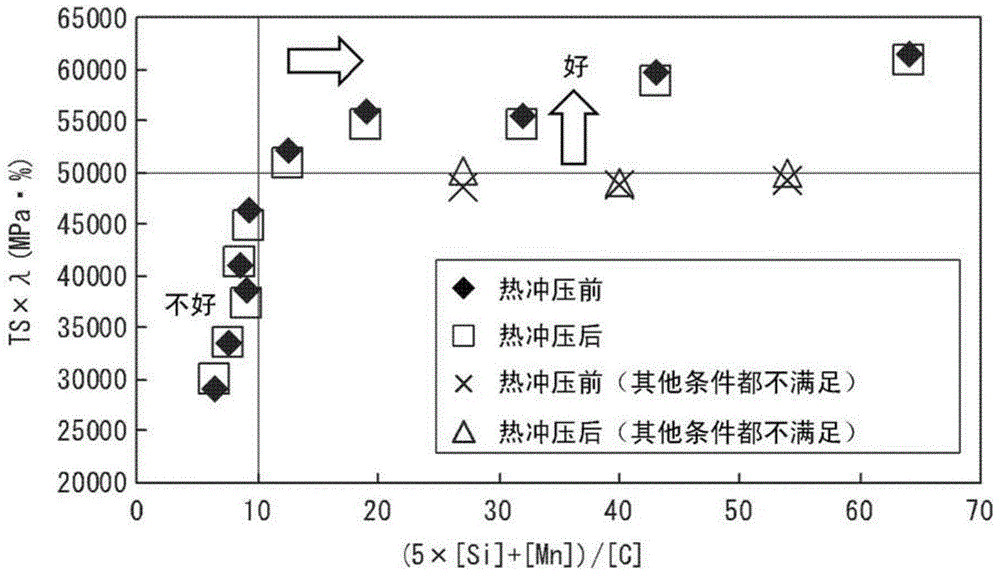

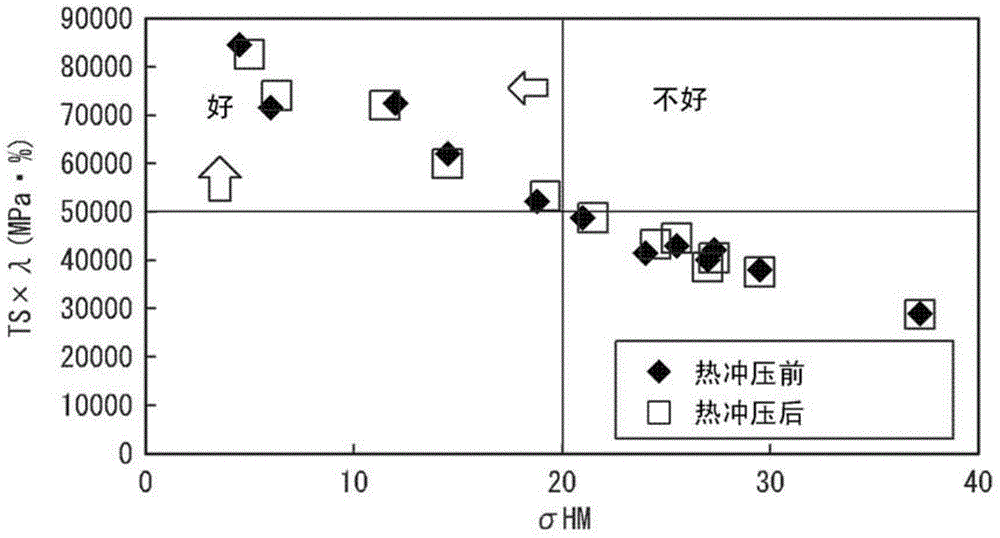

A technology of hot stamping and manufacturing methods, which is applied in the direction of manufacturing tools, furnace types, heat treatment furnaces, etc., can solve problems such as processing performance such as complicate shapes of parts, hole expandability, etc., and achieve good hole expandability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0132] After continuous casting of the steel with the composition shown in Table 1 at a casting speed of 1.0 m / min to 2.5 m / min, it is directly or temporarily cooled, and then the slab is heated in a heating furnace according to the conditions in Table 2 according to a conventional method, at a temperature of 910 to 2.5 m / min. Hot rolling was performed at a finish rolling temperature of 930° C. to produce a hot-rolled steel sheet. Then, this hot-rolled steel sheet was coiled at the coiling temperature CT shown in Table 2. Thereafter, pickling is performed to remove scale on the surface of the steel sheet, and the sheet is cold rolled to a thickness of 1.2 to 1.4 mm. At this time, cold rolling was performed so that the value of Formula e became the value shown in Table 2. After cold rolling, annealing was performed at the annealing temperatures shown in Table 3 and Table 4 in a continuous annealing furnace. Hot-dip galvanizing is further performed on a part of the steel sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com