Three-dimensional terry flannelette fabric and manufacturing method thereof

A technology of three-dimensional plush flannelette and fabric, which is applied in liquid/gas/steam textile material treatment, fabric surface trimming, and textile material treatment, etc. Poor ball performance and other problems, to avoid fluffing, improve anti-pilling performance, and increase bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

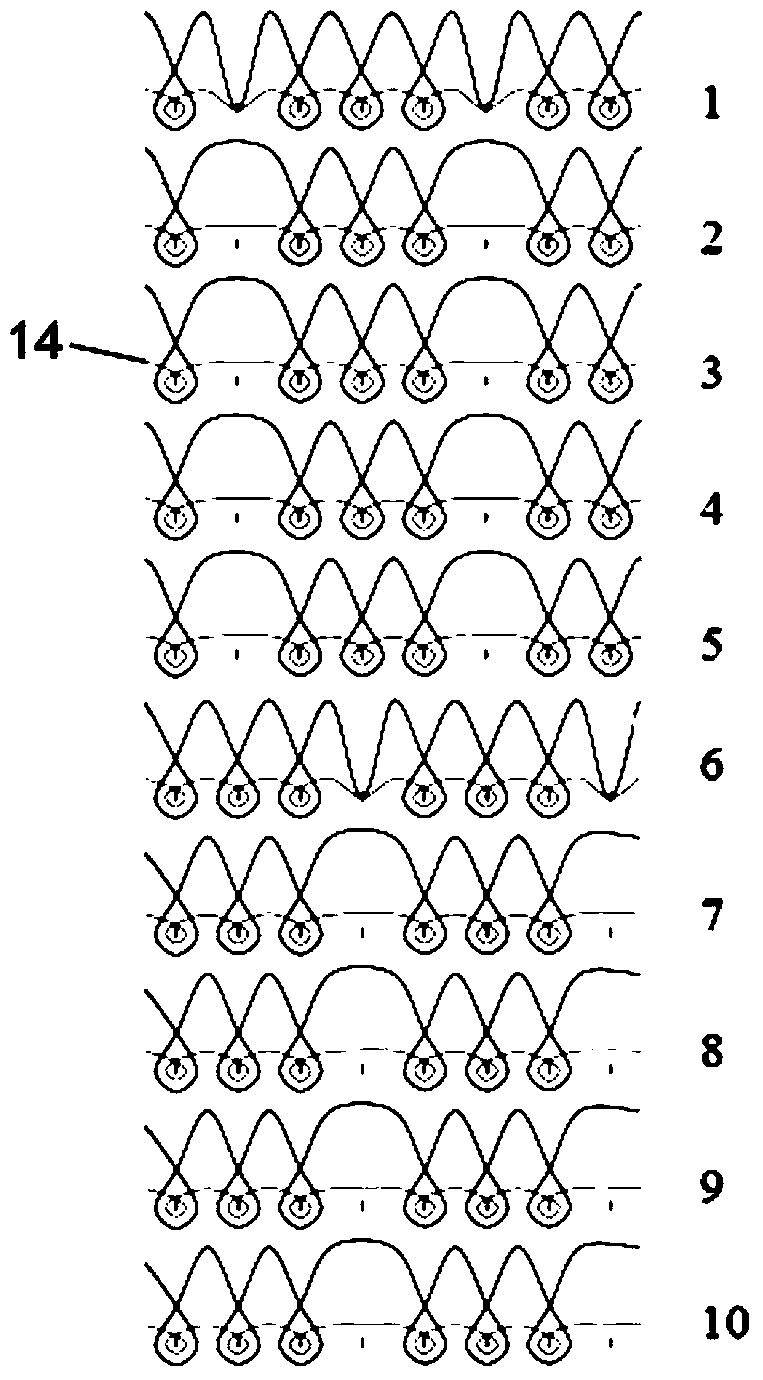

[0047] Weaving process:

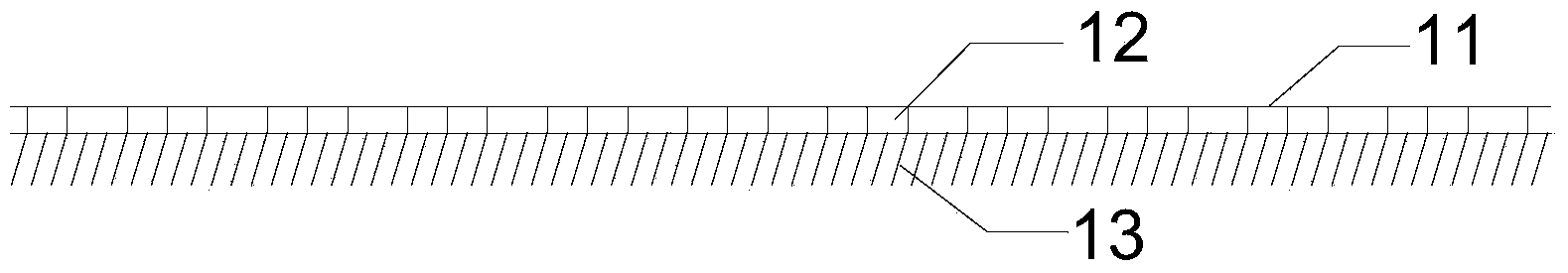

[0048] Select FDY polyester yarn of 150D / 96F, DTY polyester yarn of 75D / 36F and 200D / 96F, and adopt ABAC knitting needle arrangement for interweaving and weaving. The first way adopts AC plating to form loops, and B plating tuck process; the second, Routes 3, 4 and 5 adopt AC plating to form loops and B floating thread technology; No. 6 adopts AB plating to form loops and C plating tuck technology; No. 7, 8, 9 and 10 adopt AB plating to form loops , C Plating Floating Line Process; After the above 10 ways of feeding yarn, a blank with a honeycomb structure on both sides is formed. On a 14G weft knitting single-sided multi-needle track circular machine with 75D / 36F: 15cm loop length weaving grammage 350g / m 2 rough.

[0049] Handling rough process:

[0050] Firstly, under the conditions of 180°C and 20% overfeed, preform the blank at a speed of 20m / min. Then at 80°C, add 0.04g / L silicone defoamer and 3g / L degreaser at a bath ratio of 1:12 for pre-dy...

Embodiment 2

[0052] Weaving process:

[0053] Select FDY polyester yarn of 150D / 96F, DTY polyester yarn of 75D / 36F and 200D / 96F, and adopt ABAC knitting needle arrangement for interweaving and weaving. The first way adopts AC plating to form loops, and B plating tuck process; the second, Routes 3, 4 and 5 adopt AC plating to form loops and B floating thread technology; No. 6 adopts AB plating to form loops and C plating tuck technology; No. 7, 8, 9 and 10 adopt AB plating to form loops , C Plating Floating Thread Process; Through the above 10 ways of feeding yarn to form a blank with a honeycomb structure on both sides, weaving a grammage of 390g / m on a 18G weft knitting single-sided multi-needle track circular machine with a loop length of 75D / 36F: 10cm 2 rough.

[0054] Handling rough process:

[0055] First pre-form blanks at 180°C, 45% overfeed, and 35m / min speed. Then at 100°C, with a bath ratio of 1:10, add 0.1g / L silicone defoamer and 1g / L degreasing agent for pre-dyeing treatmen...

Embodiment 3

[0057] Weaving process:

[0058] Select FDY polyester yarn of 150D / 96F, DTY polyester yarn of 75D / 36F and 200D / 96F, and adopt ABAC knitting needle arrangement for interweaving and weaving. The first way adopts AC plating to form loops, and B plating tuck process; the second, Routes 3, 4 and 5 adopt AC plating to form loops and B floating thread technology; No. 6 adopts AB plating to form loops and C plating tuck technology; No. 7, 8, 9 and 10 adopt AB plating to form loops , C Plating Floating Thread Process; Through the above 10 ways of feeding yarn to form a blank with a honeycomb structure on both sides, weaving it on a 20G weft knitting single-sided multi-needle track circular machine with a loop length of 75D / 36F: 20cm and a grammage of 370g / m 2 rough.

[0059] Handling rough process:

[0060] First pre-form blanks at 180°C, 30% overfeed, and 25m / min vehicle speed. Then at 90°C, add 0.07g / L silicone defoamer and 2g / L degreaser at a bath ratio of 1:15 for pre-dyeing tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com