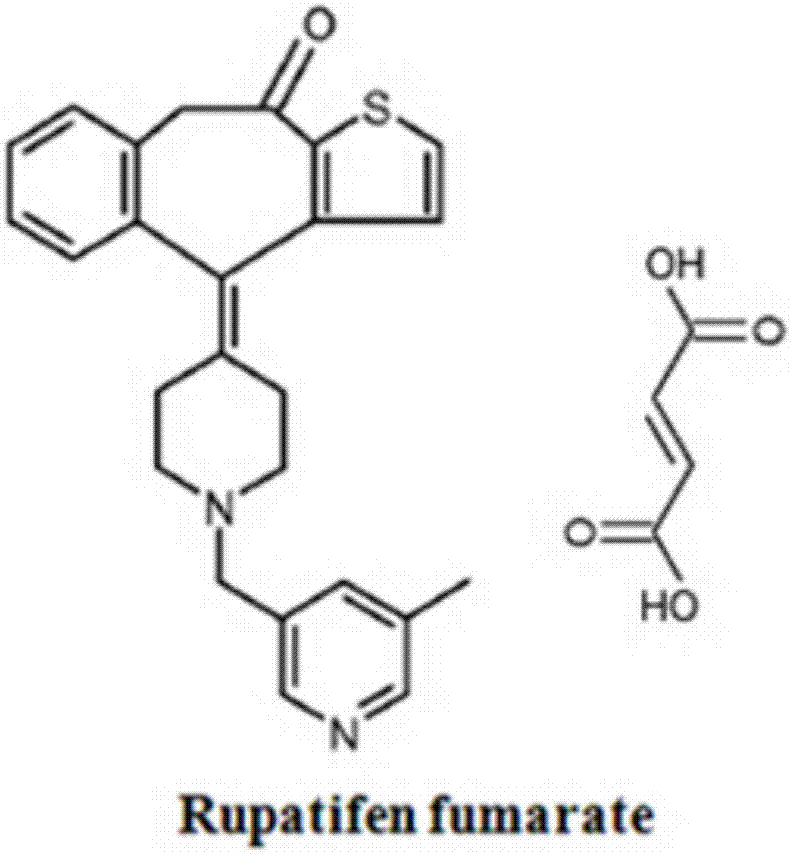

A kind of rupatifene fumarate mixed crystal and preparation method thereof

A fumaric acid, mixed crystal technology, applied in organic chemistry and other directions, to achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

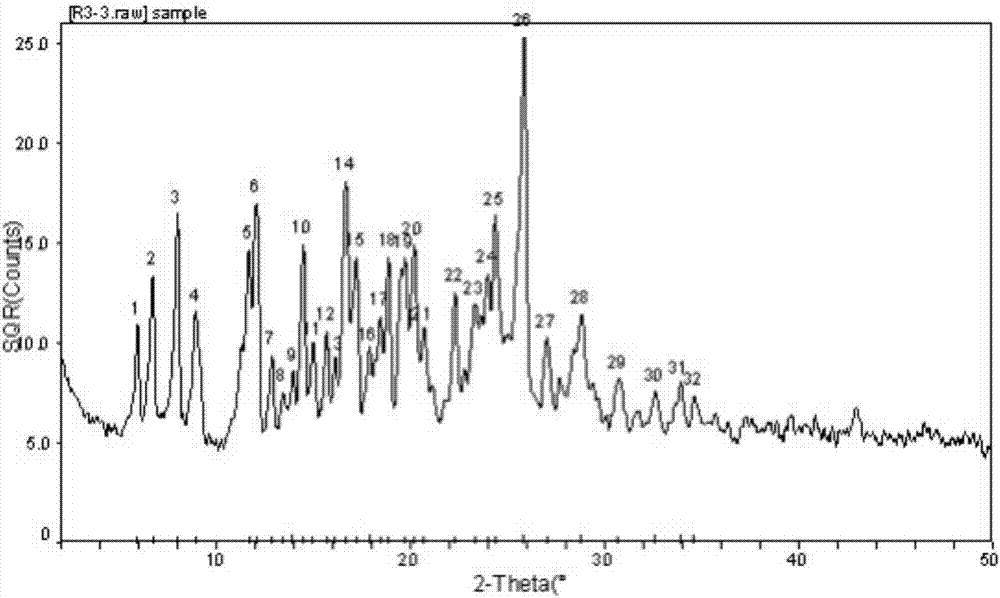

Image

Examples

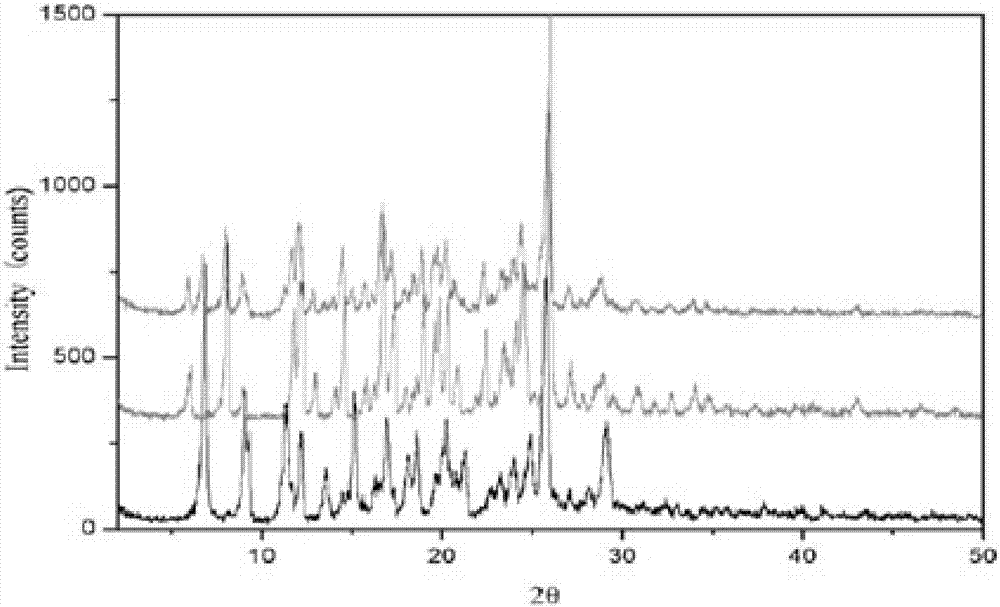

Embodiment 1

[0020] Dissolve 1.0g rupatifene free base and 1.0g fumaric acid in an appropriate amount of 20ml 95% ethanol solution, stir and react at room temperature for 1hr, concentrate under reduced pressure to 25-30% volume, and cool the solution naturally to room temperature, then in Static crystallization at 2-8°C, rod-shaped crystals precipitated, filtered, washed with 95% ethanol solution at 2-8°C, dried under reduced pressure at 45°C, and obtained.

Embodiment 2

[0022] Weigh 2.0g rupatifene free base and 0.5g fumaric acid and dissolve in an appropriate amount of 50ml 95% ethanol solution, stir and react at room temperature for 2hr, concentrate under reduced pressure to 25-30% volume, and cool the solution naturally to room temperature, then Static crystallization at 2-8°C, rod-shaped crystals precipitated, filtered, washed with 95% ethanol solution at 2-8°C, dried under reduced pressure at 45°C, and obtained.

Embodiment 3

[0024] Dissolve 1.0g rupatifene free base and 2.0g fumaric acid in an appropriate amount of 20ml 95% ethanol solution, stir and react at room temperature for 1hr, concentrate under reduced pressure to 25-30% volume, and cool the solution naturally to room temperature, then Static crystallization at 2-8°C, rod-shaped crystals precipitated, filtered, washed with 95% ethanol solution at 2-8°C, dried under reduced pressure at 45°C, and obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com