Polymer cement mortar for slab ballastless track of high-speed railway

A slab-type ballastless track and cement mortar technology, which is applied in the field of rail transit engineering materials, can solve the problems of large shrinkage deformation, insufficient early strength and high cost, achieve low shrinkage and micro-expansion characteristics, and achieve the effects of setting time and high early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

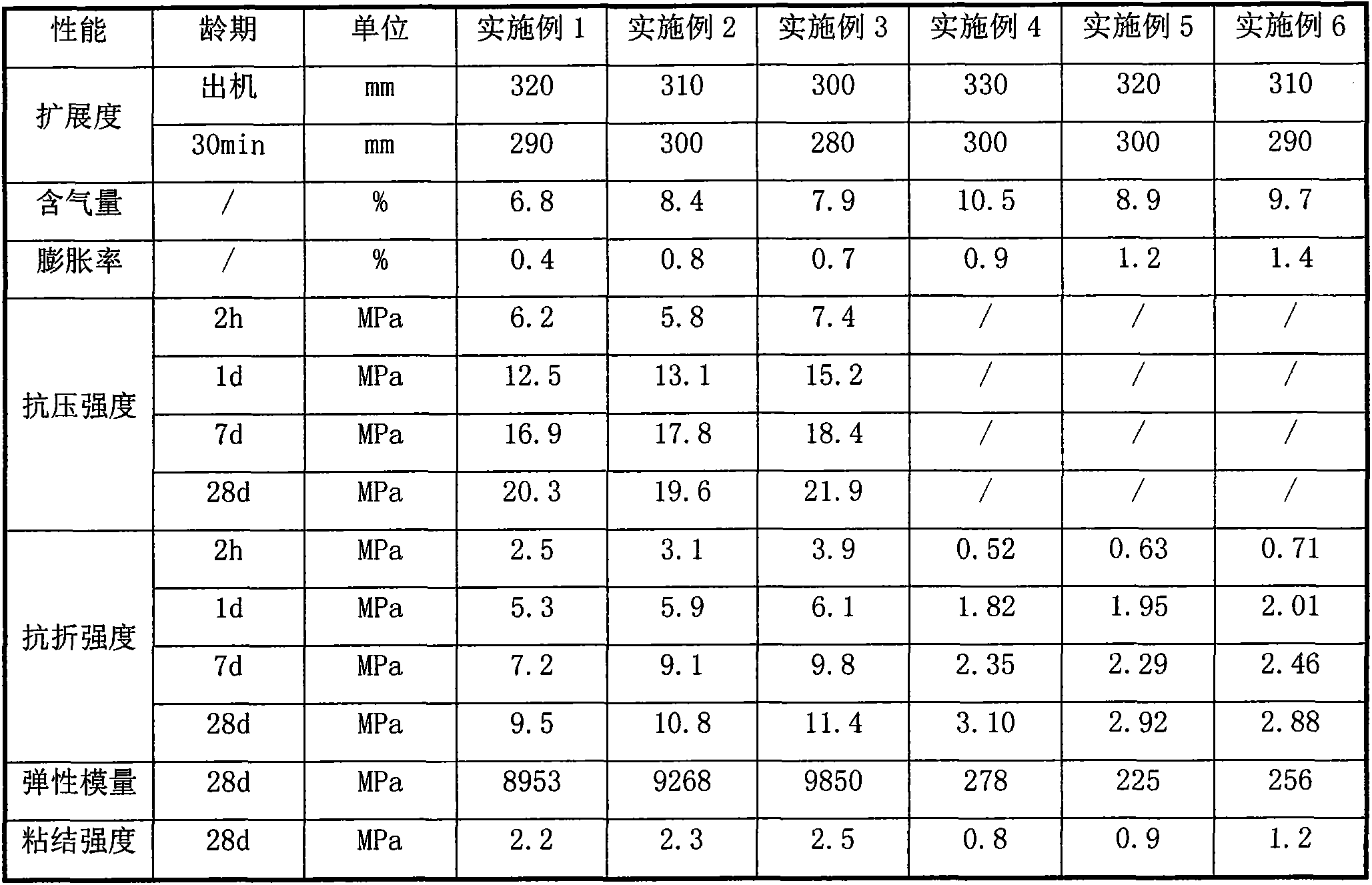

Examples

Embodiment 1

[0046] Composition of polymer cement mortar:

[0047] Solid material is made up of the raw material of following weight fraction:

[0048] Cementitious material components: 50 parts of ordinary portland cement, 10 parts of sulphoaluminate cement, 30 parts of fly ash, 10 parts of limestone powder;

[0049] Elasticity adjustment component: 1 part of sulfonated asphalt powder;

[0050] Expansion components: 0.02 parts of aluminum powder, 10 parts of magnesium oxide expansion agent;

[0051] Internal maintenance components: 0.01 parts of starch-based water-absorbing resin;

[0052] Aggregate component: 130 parts of river sand;

[0053] Coagulation regulating components: 0.002 part of lithium carbonate, 0.008 part of tartaric acid.

[0054] Liquid material is made up of the raw material of following weight fraction:

[0055] 100 parts of styrene-butadiene latex;

[0056] 1 part of melamine water reducer, 1 part of naphthalene water reducer;

[0057] 1 part polyether defoamer...

Embodiment 2

[0064] Composition of polymer cement mortar:

[0065] Solid material is made up of the raw material of following weight fraction:

[0066] Cementitious material components: 56 parts of sulfoaluminate cement, 20 parts of fly ash, 5 parts of silica fume, 19 parts of mineral powder;

[0067] Elasticity adjustment component: 5 parts of sulfonated asphalt powder;

[0068] Expansion components: 0.03 parts of aluminum powder, 9 parts of calcium sulfoaluminate expansion agent;

[0069] Internal maintenance components: 0.06 parts of acrylamide water-absorbing resin 0.04 parts of starch water-absorbing resin;

[0070] Aggregate component: 118 parts of quartz sand;

[0071] Coagulation regulating components: 0.2 part of lithium carbonate, 0.5 part of citric acid.

[0072] Liquid material is made up of the raw material of following weight fraction:

[0073] 62 parts of styrene-acrylic emulsion, 38 parts of styrene-butadiene latex;

[0074] 1.2 parts of polycarboxylate superplasticiz...

Embodiment 3

[0082] Composition of polymer cement mortar:

[0083] Solid material is made up of the raw material of following weight fraction:

[0084] Cementitious material components: 68 parts of sulphoaluminate cement, 15 parts of metakaolin, 17 parts of phosphorus slag powder;

[0085] Elasticity adjustment component: 4 parts of vitrified microbeads;

[0086] Expansion components: 0.1 parts of aluminum powder, 14.9 parts of calcium sulfoaluminate expansion agent;

[0087] Internal maintenance components: 0.1 parts of acrylamide water-absorbing resin;

[0088] Aggregate component: 98 parts of machine-made sand;

[0089] Coagulation regulating components: 0.1 part of lithium oxalate, 0.3 part of triethanolamine, 0.2 part of calcium sugar, and 0.05 part of gluconate.

[0090] Liquid material is made up of the raw material of following weight fraction:

[0091] 90 parts of polyacrylate emulsion, 10 parts of neoprene emulsion;

[0092] 0.8 parts of polycarboxylate water reducer;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com