Stone sound box making method

A manufacturing method and speaker technology, applied in imitation of natural patterns, decorative arts, special patterns, etc., can solve the problems of peeling paint, unstable positioning structure of large metal mesh covers, and slow manufacture of stone speakers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The novelty and other characteristics of the present invention will become clearer with the detailed description of the preferred embodiments in the accompanying drawings.

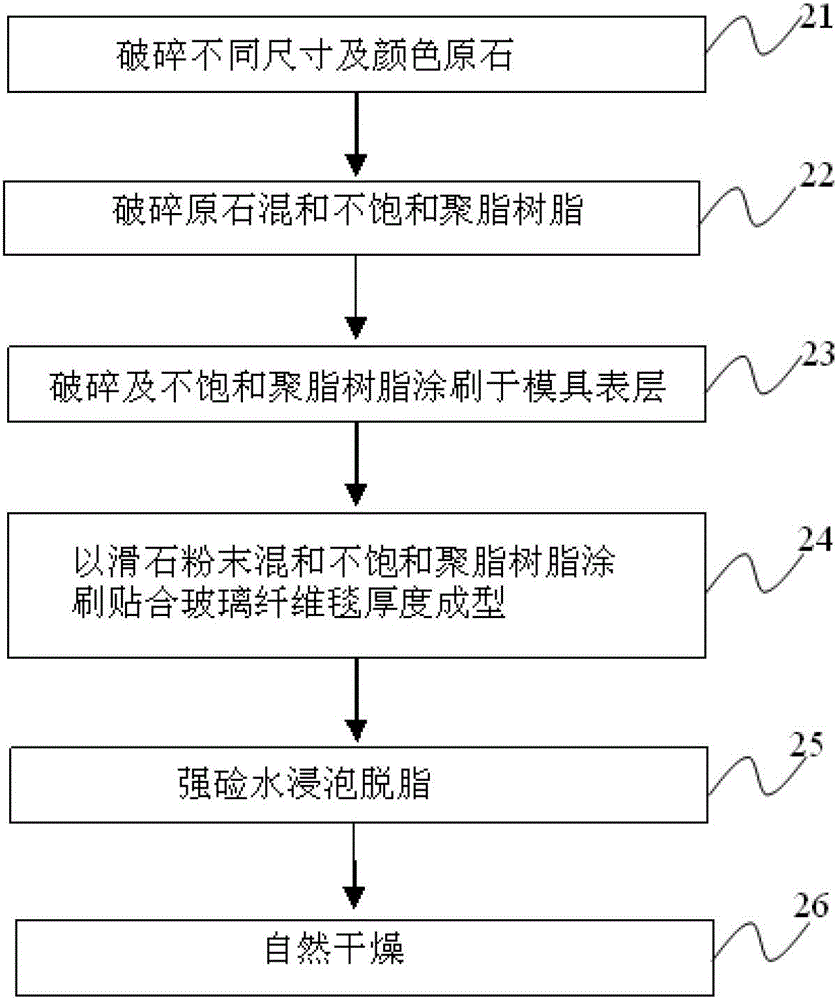

[0029] Such as figure 2 As shown, in the manufacturing process of the illustrated feasible embodiment, the present invention at least includes the following steps:

[0030] Select rough stones of different sizes and colors, and crush the raw stone materials (step 21);

[0031] mixing the crushed rough stone with unsaturated polyester resin (step 22);

[0032] Applying the crushed raw stone and unsaturated polyester resin to the mold surface (step 23);

[0033] Mix talc powder and unsaturated polyester resin to paint and fit the thickness of the glass fiber blanket to form a stone speaker (step 24);

[0034] Degrease by soaking in strong alkaline water (step 25); and

[0035] Let dry naturally (step 26).

[0036] The stone speaker made by the above manufacturing method itself has the appearance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com