Method for manufacturing bamboo particleboards through modification of hickory nut epicarp

A technology for bamboo particleboard and exocarp, which is applied in the field of manufacturing bamboo particleboard, can solve the problem that bamboo particleboard has not been reported in literature, etc., and achieves the effects of promoting industrial development, excellent product performance, and improving comprehensive utilization rate of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Pre-treatment of the hickory exocarp: collect the hickory exocarp, dry it to a moisture content below 3%, crush it, and screen the powder with a particle size of less than 40 mesh;

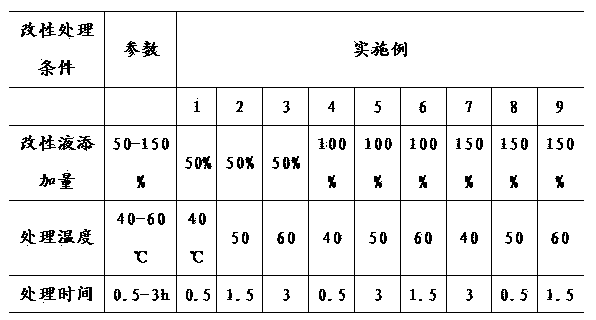

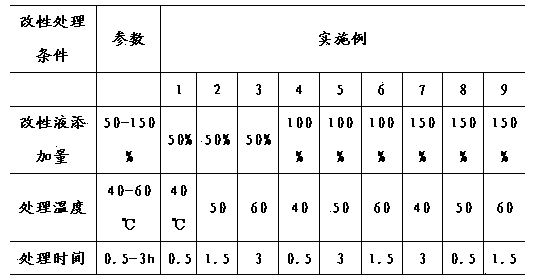

[0030] (2) Preparation of modified liquid: Mix the raw materials and content of Example 1 in Table 1 to form modified liquid; or make the content according to the amount of increase or decrease of the content shown by each raw material, such as a thousand times to a liter ( L) or kilograms (kg) is used as the content to prepare the modified liquid;

[0031] (3) Modification of the pecan exocarp powder: according to the process factors and parameters of Example 1 in Table 2, the pecan exocarp powder obtained in step (1) is modified, and the hickory exocarp powder is used The modified solution of 50% of the dry weight of the material is sprayed with a side-rolling tube. After the powder is sprayed evenly with the modified solution, it is placed in a 40°C constant temperature room fo...

Embodiment 2

[0037] The steps are the same as the method and Example 1, except that the parameters such as the amount of addition in the following steps are slightly changed: in step (2), each raw material and its content are mixed into a modified liquid according to the raw materials and content of Example 2 in Table 1; In step (3), the treatment temperature is 50°C, and the treatment time is 1.5h; in step (5), the modified hickory exocarp powder is added according to 25% of the absolute dry mass of bamboo shavings; in step (6), Add water repellent and additives according to 0.8% of the absolute dry mass of bamboo shavings.

Embodiment 3

[0039] The steps are the same as the method and Example 1, with a slight change: in step (2), each raw material and its content are mixed into a modified liquid according to the raw materials and content of Example 3 in Table 1; in the step (3), the treatment temperature is 60°C, the treatment time is 3h; in step (5), add the modified pecan exocarp powder according to the quality of 30% of the absolute dry weight of bamboo shavings; in step (6), press 0.8% of the absolute dry weight of bamboo shavings Add water repellent and additives.

[0040] All the other examples 4-9 are all mixed into modified liquid by the raw materials and contents shown in corresponding examples 4-9 in table 1 respectively and modified by the modification treatment conditions shown in corresponding examples 4-9 in table 2. sexual processing.

[0041] Among the nine examples, example 6 is preferred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com