Ferrochromium-based powder core wire and preparing method and application thereof

A technology of ferrochrome and core wire, which is applied in the direction of metal material coating process, coating, fusion spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

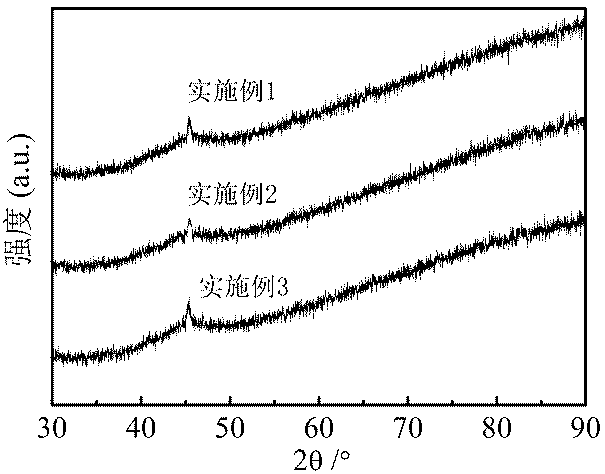

Embodiment 1

[0038] A ferrochrome-based powder core wire material, made of a stainless steel belt covering a powder core, the powder core composition is a mixture of seven element powders, and its weight percentage range is as follows: 45 % Cr, 12 % B, 4 % Si, 2 % W, 10 % Nb, the balance being Fe.

[0039] The stainless steel belt is made of 304L stainless steel belt, and the weight ratio of the powder core to the stainless steel belt is 0.43:1.

[0040] A method for preparing a ferrochrome-based powder core wire material, comprising the steps of:

[0041] (1) Mix the seven element powders of the powder core, add alcohol, and wet mix in a ball mill for 5 hours to obtain a mixture, in which the volume ratio of alcohol to powder is 0.4:1, and the weight ratio of stainless steel balls to the mixed powder in the ball mill 5:1, ball mill speed ≤150r / min;

[0042] (2) Place the mixture in a rotary evaporator, dry until the alcohol evaporates, then put the dried mixture in an oven at a temperat...

Embodiment 2

[0049] A chromium-iron-based powder core wire material, made of a stainless steel belt covering a powder core, the powder core composition is a mixture of seven element powders, and its weight percentage range is as follows: 40 % Cr, 15 % B, 5 % Si, 1 % W, 2 % Nb, and the balance is Fe.

[0050] The stainless steel belt is made of 304L stainless steel belt, and the weight ratio of the powder core to the stainless steel belt is 0.49:1.

[0051] A method for preparing a ferrochrome-based powder core wire material, comprising the steps of:

[0052] (1) Mix the seven element powders of the powder core, add alcohol, and wet mix in a ball mill for 6 hours to obtain a mixture, in which the volume ratio of alcohol to powder is 0.46:1, and the weight ratio of stainless steel balls to the mixed powder in the ball mill 6:1, ball mill speed ≤150r / min;

[0053] (2) Place the mixture in a rotary evaporator, dry until the alcohol volatilizes, then put the dried mixture in an oven at a temp...

Embodiment 3

[0060] A ferrochrome-based powder core wire material, made of a stainless steel belt covering a powder core, the powder core composition is a mixture of seven element powders, and its weight percentage range is as follows: 50 % Cr, 5 % B, 1 % Si, 3 % W, 10 % Nb, the balance being Fe.

[0061] The stainless steel belt is made of 304L stainless steel belt, and the weight ratio of the powder core to the stainless steel belt is 0.55:1.

[0062] A method for preparing a ferrochrome-based powder core wire material, comprising the steps of:

[0063] (1) Mix the seven element powders of the powder core, add alcohol, and wet mix in a ball mill for 7 hours to obtain a mixture, in which the volume ratio of alcohol to powder is 0.52:1, and the weight ratio of stainless steel balls to the mixed powder in the ball mill 7:1, ball mill speed ≤150r / min;

[0064] (2) Place the mixture in a rotary evaporator, dry until the alcohol volatilizes, then put the dried mixture in an oven at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

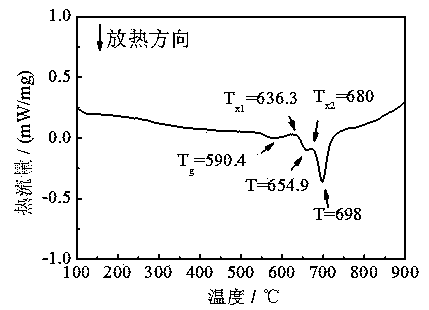

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com