A kind of high temperature resistant renewable carbon-based solid acid catalyst and preparation method thereof

A technology of solid acid catalyst and carbon-based solid acid, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the unfavorable industrial production of biodiesel and increase production Cost, long cycle and other issues, to achieve the effect of excellent thermal stability, high degree of bonding, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

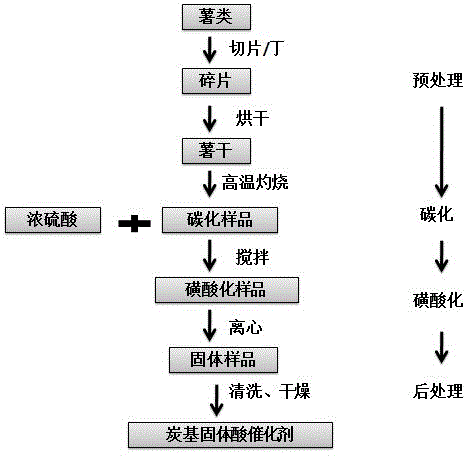

Method used

Image

Examples

Embodiment 1

[0024] (1) Take fresh sweet potatoes, wash them, remove sediment impurities, slice them (thickness 1mm), and dry them in a blast drying oven at 75°C for 2 hours to obtain dried sweet potatoes;

[0025] (2) Transfer the dried sweet potato obtained in step (1) to a muffle furnace at 400°C for 25 minutes at high temperature, and then grind the carbonized black lumps into granular substances with a mortar to obtain a carbonized sample;

[0026] (3) Add concentrated sulfuric acid with a concentration of 98% to the carbonized sample obtained in step (2) according to the ratio of solid powder to concentrated sulfuric acid of 1g:10ml (w / v), and carry out sulfonation reaction under the condition of constant mechanical stirring , the stirring speed is 800rpm, the water bath is heated, the temperature is controlled at 100°C, the reaction time is 3h, and the sulfonated sample is obtained;

[0027] (4) Filter the sulfonated sample obtained in step (3), collect the solid sample, and wash it...

Embodiment 2

[0030] (1) Wash fresh taro, remove sediment impurities, slice (thickness 10mm), and dry in a hot air drying oven at 40°C for 4 hours to obtain dried taro;

[0031] (2) Dry transfer the taro obtained in step (1) to a muffle furnace at 200°C for 2.5 hours at high temperature, and then grind the carbonized black lumps into granular substances with a mortar to obtain carbonized samples;

[0032] (3) Add concentrated sulfuric acid with a concentration of 80% to the carbonized sample obtained in step (2) according to the ratio of solid powder to concentrated sulfuric acid of 1g:15ml (w / v), and carry out sulfonation reaction under the condition of continuous magnetic stirring , the stirring speed is 100rpm, the water bath is heated, the temperature is controlled at 200°C, the reaction time is 0.5h, and the sulfonated sample is obtained;

[0033] (4) Centrifuge the sulfonated sample obtained in step (3) at a centrifugation speed of 12000rpm, collect the solid sample, and wash it conti...

Embodiment 3

[0036] (1) Take fresh yam, wash it, remove sediment impurities, slice it (thickness 20mm), and dry it in a vacuum drying oven at 120°C for 0.5h to obtain dried yam;

[0037] (2) Dry transfer the yam obtained in step (1) to a muffle furnace at 450°C for 15 minutes at high temperature, and then grind the carbonized black lumps into granular substances with a mortar to obtain a carbonized sample;

[0038] (3) Add concentrated sulfuric acid to the carbonized sample obtained in step (2) according to the ratio of solid powder to 70% concentrated sulfuric acid at a ratio of 1g:20ml (w / v), and carry out sulfonation reaction under the condition of continuous rotation and stirring , the stirring speed is 1800rpm, the water bath is heated, the temperature is controlled at 70°C, the reaction time is 5h, and the sulfonated sample is obtained;

[0039] (4) Centrifuge the sulfonated sample obtained in step (3) at a speed of 3000rpm to collect the solid sample and wash it with clean water unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com