Clad modified layered cathode material of lithium-ion battery and preparation method of layered cathode material

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of low cost, easy process control, and maintaining electrochemical inertness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Lithium nitrate (LiNO 3 ), tetrabutyl titanate (C 16 h 36 o 4 Ti), citric acid (C 6 h 8 o 7 ) as the raw material. First, an appropriate amount of tetrabutyl titanate is dissolved in ethanol solution, the volume ratio of titanium source to ethanol is 1-5, and an appropriate amount of ethylene glycol is dropped into the solution (to promote the formation of a more stable gel), and at the same time Lithium nitrate and complexing agent citric acid were dissolved in deionized water. Then, the prepared two solutions were mixed slowly under constant stirring, so that the molar ratio of the complexing agent to (Li+Ti) was 1:2, and the molar ratio of the complexing agent to ethylene glycol was 1:1. Using NH 3 ·H 2 O to adjust the pH of the solution to 5, and stir to form a suspension.

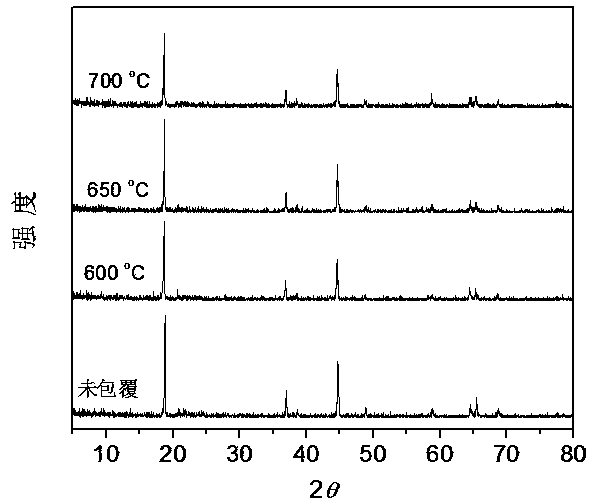

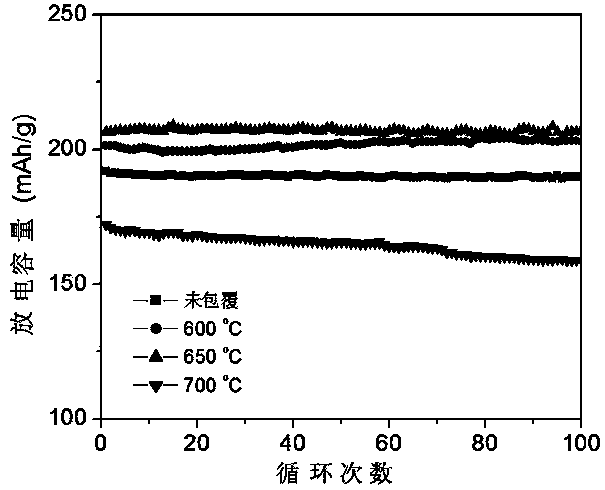

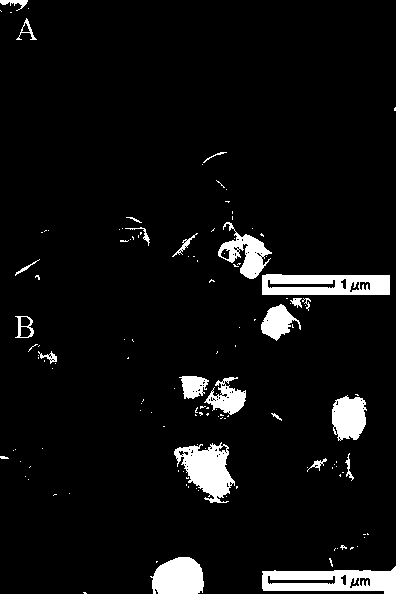

[0027] Will Li 1.2 [Mn 0.51 Ni 0.19 co 0.1 ]O 2 Add the positive electrode material into the above solution, heat and stir at 60° C., and obtain a sol with the evaporation of the ...

Embodiment 2

[0032] Lithium hydroxide (LiOH), titanium isopropoxide (Ti[OCH(CH 3 ) 2 ] 4 ), PVP (M.W.30000) as raw materials. First, an appropriate amount of titanium isopropoxide is dissolved in ethanol solution, the volume ratio of titanium source to ethanol is 1-10, and an appropriate amount of ethylene glycol is dropped into the solution, and lithium hydroxide and complexing agent PVP are dissolved in deionized water. Then the prepared two solutions were mixed slowly under constant stirring, the molar ratio of complexing agent to (Li+Ti) was 1:0.5, and the molar ratio of complexing agent to ethylene glycol was 1:2. Then adjust the pH value of the solution to 6 with acetic acid solution, and stir to form a suspension.

[0033] Will Li[Ni 0.5 co 0.2 mn 0.3 ]O 2 Add the positive electrode material into the above solution, heat and stir at 50° C., and obtain a sol with the evaporation of the solvent. Place in a blast drying oven and dry at 90°C for 24 hours to obtain the coated pr...

Embodiment 3

[0035] Lithium carbonate (Li 2 CO 3 ), titanium tetrachloride (TiCl 4 ), PEG2000 are raw materials. First, dissolve an appropriate amount of titanium tetrachloride in ethanol solution, the volume ratio of titanium source and ethanol is 1-6, and drop an appropriate amount of ethylene glycol into the solution, and dissolve lithium carbonate and complexing agent PEG2000 in the solution at the same time. ionized water. Then, the prepared two solutions were mixed slowly under constant stirring, so that the molar ratio of the complexing agent to (Li+Ti) was 1:1, and the molar ratio of the complexing agent to ethylene glycol was 1:1.5. Adjust the pH value of the solution to 7 with acetic acid solution, and stir to form a suspension.

[0036] LiCoO 2 The cathode material was added to the above solution, heated and stirred at 80° C., and a sol was obtained as the solvent evaporated. Place in a vacuum oven and dry at 120° C. for 12 hours to obtain the coated precursor. The precur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com