Touch substrate, manufacturing method thereof, and touch screen using the touch substrate

A substrate and touch technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problem of reduced conductivity of the grid-shaped conductive layer, achieve low resistivity, simplify the process, and improve The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The touch substrate, its manufacturing method, and the touch screen using the touch substrate will be further described below in conjunction with the accompanying drawings and specific embodiments.

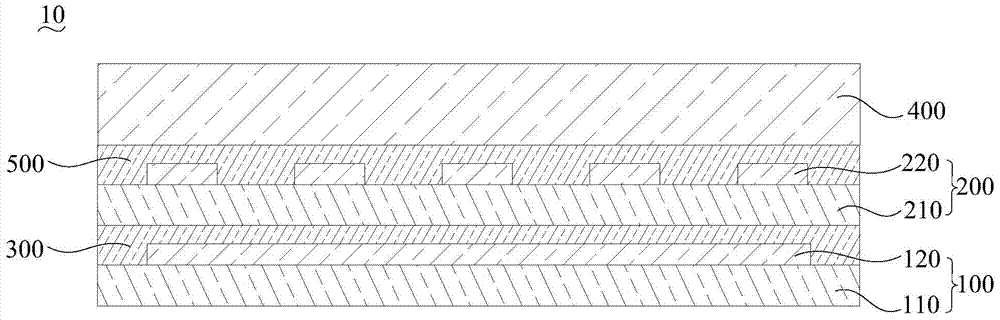

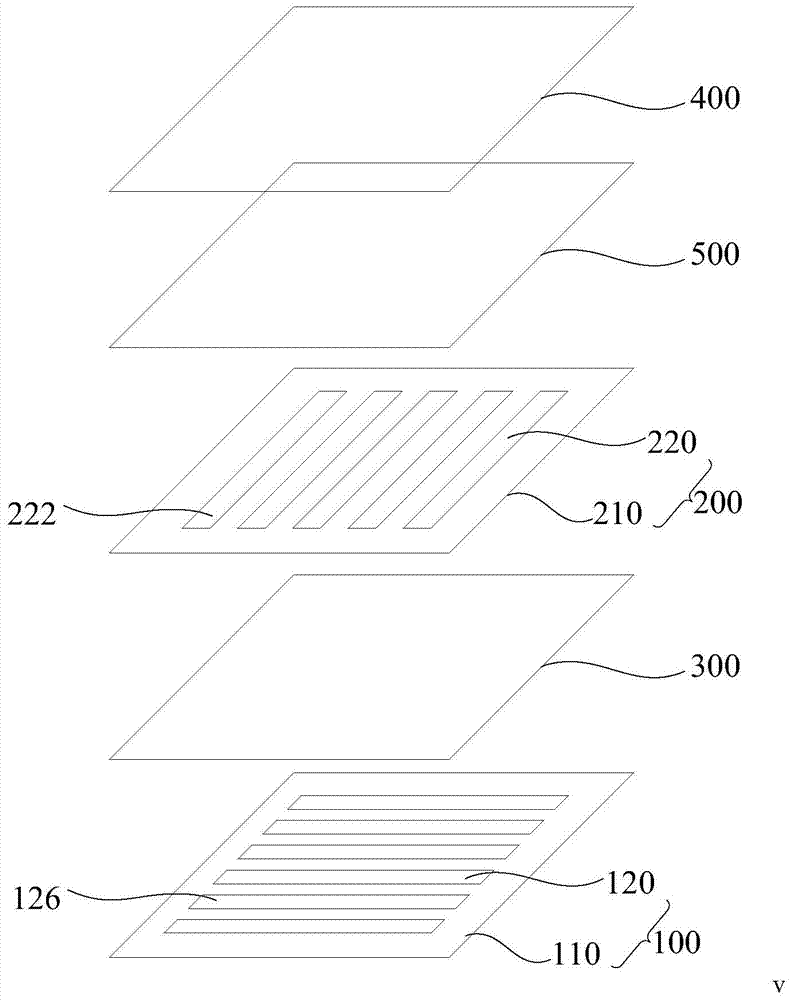

[0064] like figure 1 and figure 2 As shown, the touch screen 10 according to one embodiment includes a first touch substrate 100 , a second touch substrate 200 , a first transparent optical adhesive layer 300 , a protective panel 400 and a second transparent optical adhesive layer 500 .

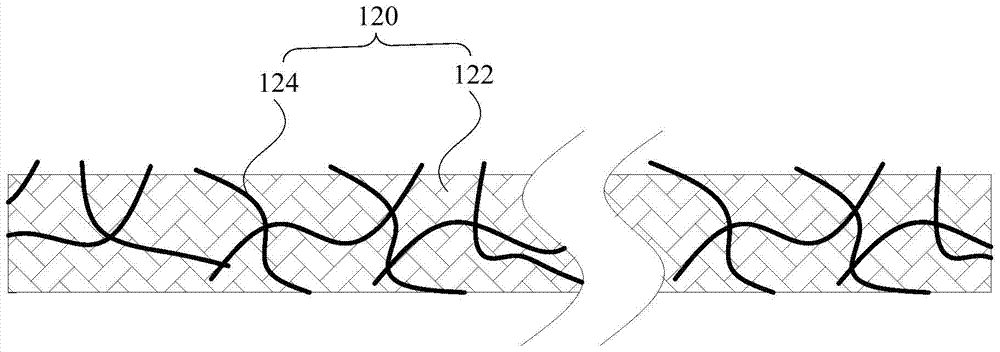

[0065] The first touch control substrate 100 includes a first transparent substrate 110 and a first conductive layer 120 .

[0066] The material of the first transparent substrate 110 can be glass, polymethyl methacrylate, polycarbonate, polyethylene terephthalate, cycloolefin copolymer or cycloolefin polymer. The thickness of the first transparent substrate 110 is 0.02mm˜0.5mm. Further, in this embodiment, after comprehensively considering the processing difficulty of the first transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com