Zero-polar-distance ion exchange membrane and preparation method thereof

An ion exchange membrane and zero-pole distance technology, applied in the field of ion membrane, can solve the problems of reduced anti-foaming function, low anti-foaming ability, and difficulty in large-area implementation, so as to reduce surface resistance and cell voltage, and reduce accumulation. , good anti-foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Including the following preparation methods:

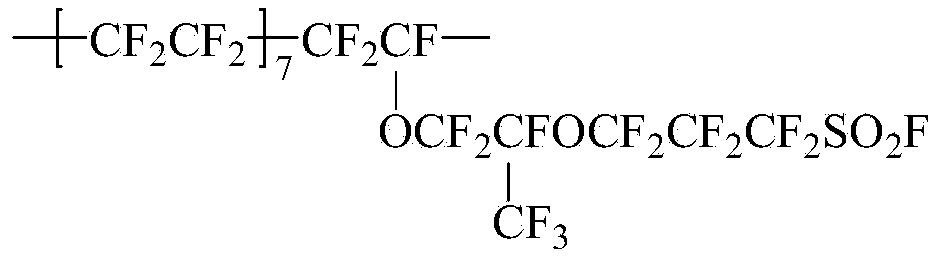

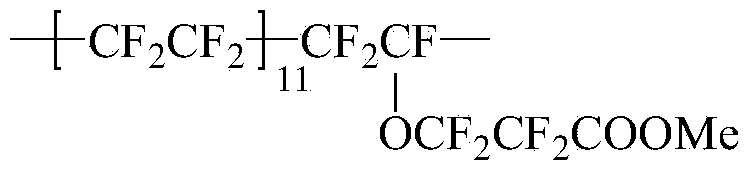

[0049] (1) The perfluorosulfonic acid resin of IEC=1.4mmol / g, the perfluorosulfonic acid carboxylic acid copolymer resin of IEC=1.0mmol / g and the perfluorocarboxylic acid resin of IEC=0.95mmol / g, according to the mass parts The ratio is 100:5:10 and composited into a composite film by co-extrusion casting, with a total thickness of 135 microns. At the same time, PTFE mesh cloth is introduced between the film forming rollers, and the polymer film is formed by rolling and compounding into the film body.

[0050] (2) Immerse the polymer membrane in step (1) in a mixed aqueous solution containing 15wt% dimethyl sulfoxide and 20wt% NaOH at 85° C. for 80 minutes to convert it into an ion exchange membrane with ion exchange function.

[0051] (3) Water and ethanol are formulated into a mixed solution according to a weight ratio of 1:1, and then the perfluorosulfonic acid resin of IEC=0.9mmol / g is dissolved into the water-alcohol ...

Embodiment 2

[0060] The same method as in Example 1 was used to prepare an ion exchange membrane with ion exchange function. Afterwards, water and ethanol are formulated into a mixed solution according to a weight ratio of 1:1, and then the fluorine-containing sulfonic acid resin with IEC=0.9mmol / g is dissolved into the water-alcohol mixed solution to form a sulfonic acid resin solution with a concentration of 6wt%. ; Add IEC=0.45mmol / g, average particle diameter of 0.05 micron, perfluorosulfonic acid resin crushed microparticles with irregular polyhedral appearance to the above solution, homogenize in a ball mill, and form a content of 9wt% Dispersions. Using the method of spraying, the dispersion liquid is attached to the surface of both sides of the above-mentioned ion exchange membrane with ion exchange function, and after drying, a discontinuous porous gas release layer with a porosity of 91% is formed, and the broken particles of perfluorosulfonic acid resin are compounded The distr...

Embodiment 3

[0064] The same method as in Example 1 was used to prepare an ion exchange membrane with ion exchange function. After that, water and propanol are formulated into a mixed solution according to a weight ratio of 1:1, and then the fluorine-containing sulfonic acid resin with IEC=0.9mmol / g is dissolved into the water-alcohol mixed solution to form a sulfonic acid resin with a concentration of 1wt%. solution; then add IEC=0.75mmol / g, average particle diameter of 5 microns, and broken particles of perfluorosulfonic acid resin with irregular polyhedral morphology into the above solution, and homogenize them in a ball mill to form a content of 4.6wt % of the dispersion. By brushing, the dispersion liquid is attached to the surface of both sides of the above-mentioned ion exchange membrane with ion exchange function, and after drying, a discontinuous porous gas release layer with a porosity of 94% is formed, and the broken particles of perfluorosulfonic acid resin are The distributio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com