Preparation method, product and application of porous titanium hydrogen phosphate material

A phosphate and porous titanium technology, applied in the field of porous materials, can solve problems such as difficult large-scale production, long production cycle, and difficult production, and achieve the effects of short cycle, easy use, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. According to CuO60%, TiO 2 10%, P 2 o 5 30% molar composition select raw materials, CuO, TiO 2 The raw material for the oxide itself, P 2 o 5 The raw material is phosphoric acid solution (85wt%).

[0032] 2. Mix copper oxide and titanium oxide powder materials evenly, then add phosphoric acid solution and appropriate amount of water, mix evenly, heat at 200°C for 24 hours, pulverize for later use, and obtain a mixture.

[0033] 3. Put the mixture in step 2 into the crucible, raise the temperature from room temperature to 1250°C at a rate of 5°C / min, and keep warm at 1250°C to completely melt the mixture. The molten sample is poured into the mold, the surface of the sample is cooled by water to form a block sample, and the block sample is cooled to room temperature for later use.

[0034] 4. Raise the bulk sample to 510°C at a rate of 5°C / min, and keep it for 1 hour, then raise the temperature from 510°C to 665°C at a rate of 5°C / min, and keep it for 2 hours. A...

Embodiment 2

[0039] 1. According to CuO55%, TiO 2 15%, P 2 o 5 30% molar composition select raw materials, CuO, TiO 2 The raw material for the oxide itself, P 2 o 5 The raw material is phosphoric acid solution (85wt%).

[0040] 2, with embodiment 1.

[0041] 3, with embodiment 1.

[0042] 4. Raise the temperature of the sample to 520°C at a rate of 5°C / min, and keep it for 1 hour, then raise the temperature from 520°C to 662°C at a rate of 5°C / min, and keep it for 2 hours. After the heat preservation, the samples were cooled to room temperature with the furnace.

[0043] 5. Soak the sample obtained in step 4 in 1 mol / L hydrochloric acid at 80° C. for 24 hours, and take it out to obtain a porous titanium hydrogen phosphate material.

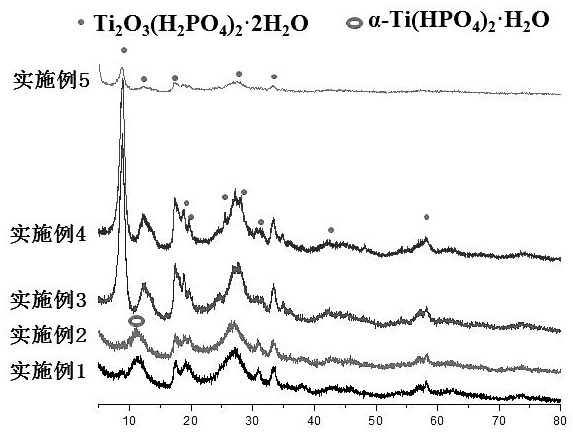

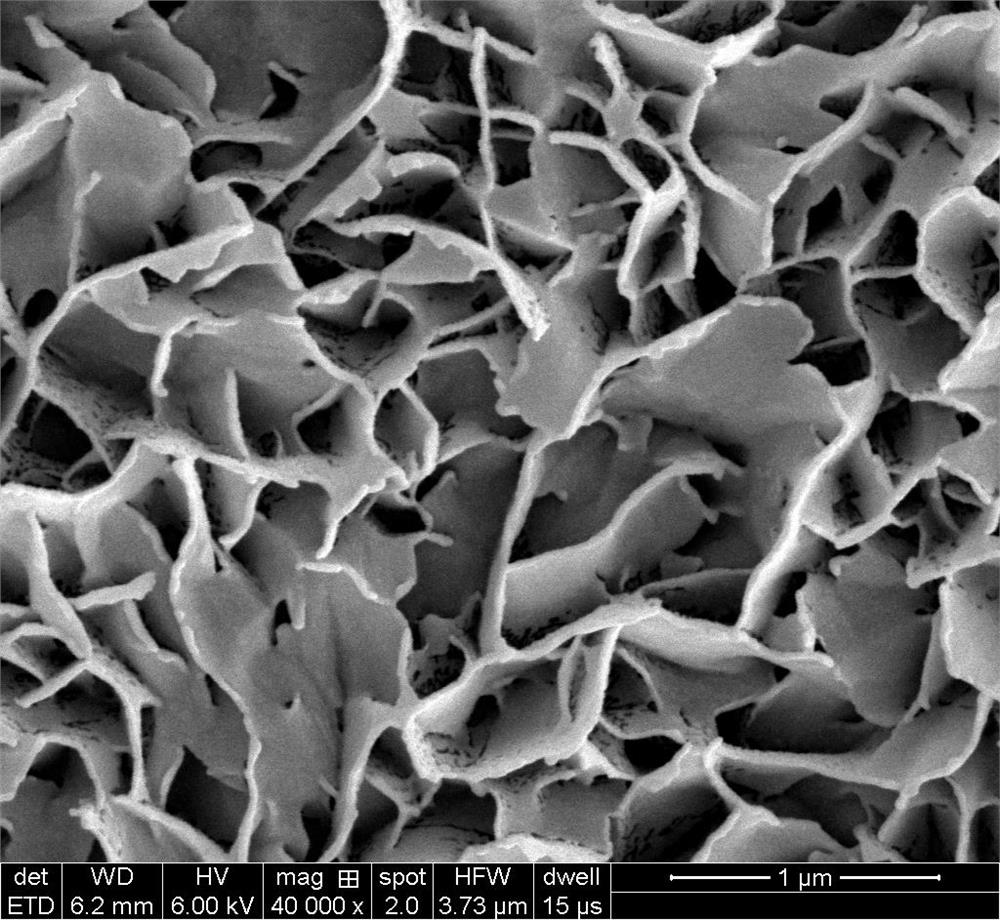

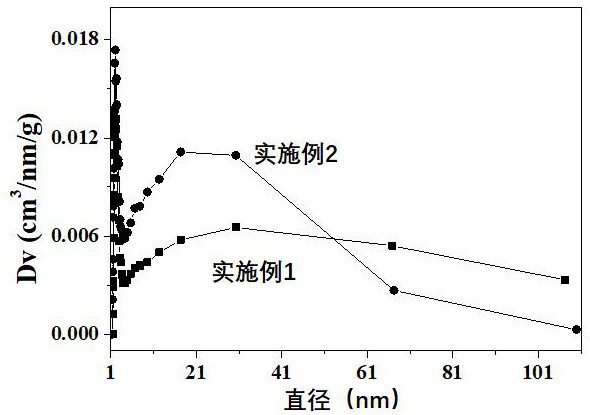

[0044] The sample is a bulk material. According to XRD analysis, the crystallization of the product is very weak, and it contains titanium hydrogen phosphate phase Ti 2 o 3 (H 2 PO 4 ) 2 2H 2 O, and a small amount of α-Ti(HPO 4 ) 2 ·H 2 O crys...

Embodiment 3

[0047] 1. According to ZnO15%, CuO40%, TiO 2 15%, P 2 o 5 30% molar composition selection of raw materials, ZnO, CuO, TiO 2 The raw material for the oxide itself, P 2 o 5 The raw material is phosphoric acid solution (85wt%).

[0048] 2. Mix zinc oxide, copper oxide and titanium oxide powder raw materials evenly, then add phosphoric acid solution and appropriate amount of water, mix evenly, heat at 200°C for 24 hours, pulverize for later use, and obtain a mixture.

[0049] 3, with embodiment 1.

[0050] 4. Raise the sample to 518°C at a heating rate of 5°C / min, and keep it for 1 hour, then raise it from 518°C to 646°C at a heating rate of 5°C / min, and hold it for 2 hours. After the heat preservation, the samples were cooled to room temperature with the furnace.

[0051] 5. Soak the sample obtained in step 4 in 1 mol / L hydrochloric acid at 80° C. for 24 hours, and take it out to obtain a porous titanium hydrogen phosphate material.

[0052] According to XRD analysis, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com