Non-toxic water-based microcapsule mold-proof heat insulation coating and preparation method thereof

A thermal insulation coating and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, antifouling/underwater coating, etc., can solve the problems of short validity period, no heat insulation, poor water resistance, etc., and achieve extended use Longevity, low price, enhanced anti-mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take the following ingredients:

[0031] (1) Silicone-modified acrylate self-emulsifying emulsion, the number of parts by mass of which is 50 parts;

[0032] (2) nontoxic antifungal agent microcapsules, its mass parts are 10 parts;

[0033] The preparation method of described nontoxic antifungal agent microcapsules is as follows:

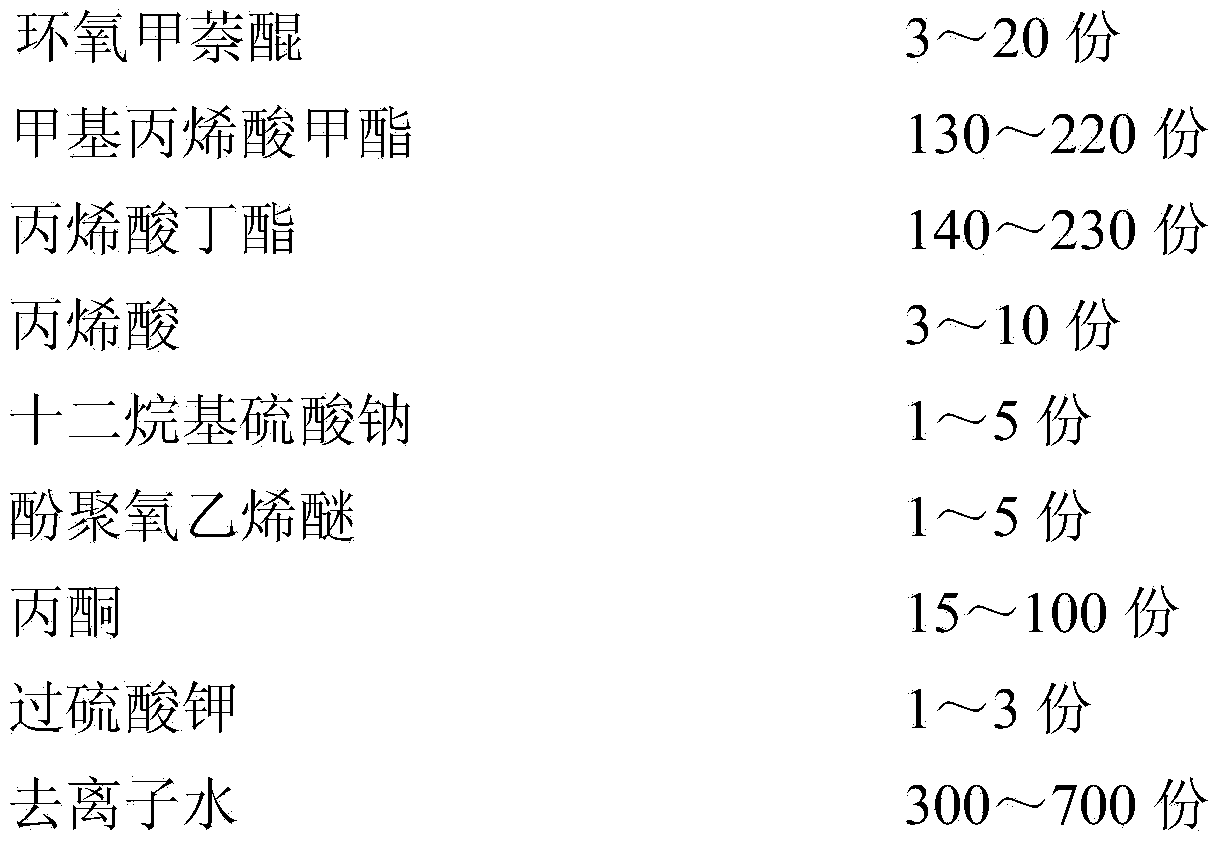

[0034] The mass number of lipophilic antifouling agents such as menadione epoxy is 5 parts, the mass number of methyl methacrylate is 130 parts; the mass number of butyl acrylate is 140 parts, and the mass number of acrylic acid is 3 parts Parts, the mass fraction of sodium lauryl sulfate is 1 part, the mass fraction of phenol polyoxyethylene ether is 1 part, the mass fraction of acetone is 15 parts, the mass fraction of potassium persulfate is 1 part, deionized water The mass parts number is 300 parts. First mix 5 parts of epoxy menadione and other lipophilic antifouling agents with 15 parts of acetone to obtain an acetone solution of epo...

Embodiment 2

[0042] Take the following ingredients:

[0043] (1) Silicone modified acrylate self-emulsifying emulsion, the number of parts by mass is 70 parts;

[0044] (2) nontoxic antifungal agent microcapsules, its mass parts are 16 parts;

[0045]The preparation method of described nontoxic antifungal agent microcapsules is as follows:

[0046] The mass number of lipophilic antifouling agents such as menadione epoxy is 15 parts, the mass number of methyl methacrylate is 180 parts; the mass number of butyl acrylate is 190 parts, and the mass number of acrylic acid is 5 parts Parts, the mass fraction of sodium lauryl sulfate is 3 parts, the mass fraction of phenol polyoxyethylene ether is 3 parts, the mass fraction of acetone is 50 parts, the mass fraction of potassium persulfate is 2 parts, deionized water The number of mass parts is 500 parts. First mix 15 parts of epoxy menadione and other lipophilic antifouling agents with 50 parts of acetone to obtain an acetone solution of epoxy...

Embodiment 3

[0054] Take the following ingredients:

[0055] (1) Silicone modified acrylate self-emulsifying emulsion, the number of parts by mass is 90 parts;

[0056] (2) nontoxic antifungal agent microcapsules, its mass fraction is 28 parts;

[0057] The preparation method of described nontoxic antifungal agent microcapsules is as follows:

[0058] The mass number of lipophilic antifouling agents such as menadione epoxy is 20 parts, the mass number of methyl methacrylate is 220 parts; the mass number of butyl acrylate is 230 parts, and the mass number of acrylic acid is 9 parts Parts, the mass fraction of sodium lauryl sulfate is 5 parts, the mass fraction of phenol polyoxyethylene ether is 5 parts, the mass fraction of acetone is 100 parts, the mass fraction of potassium persulfate is 3 parts, deionized water The mass parts number is 700 parts. First mix 20 parts of epoxy menadione and other lipophilic antifouling agents with 100 parts of acetone to obtain an acetone solution of epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com