Preparation method of carbon film coated platinum/graphene catalyst

A graphene and catalyst technology, applied in the field of platinum/graphene catalyst preparation, to achieve excellent reactivity and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

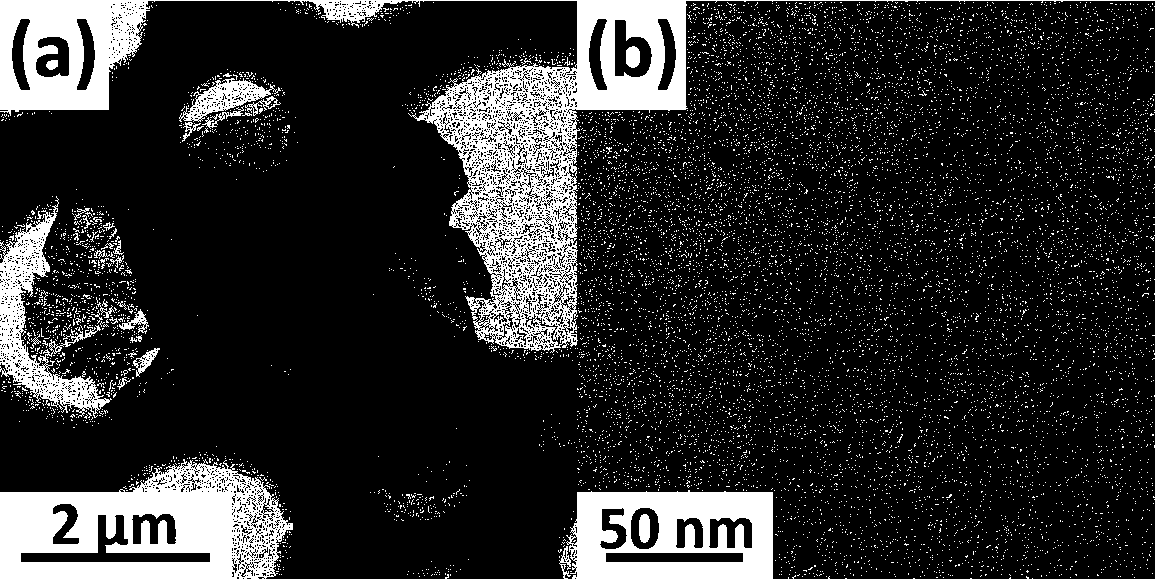

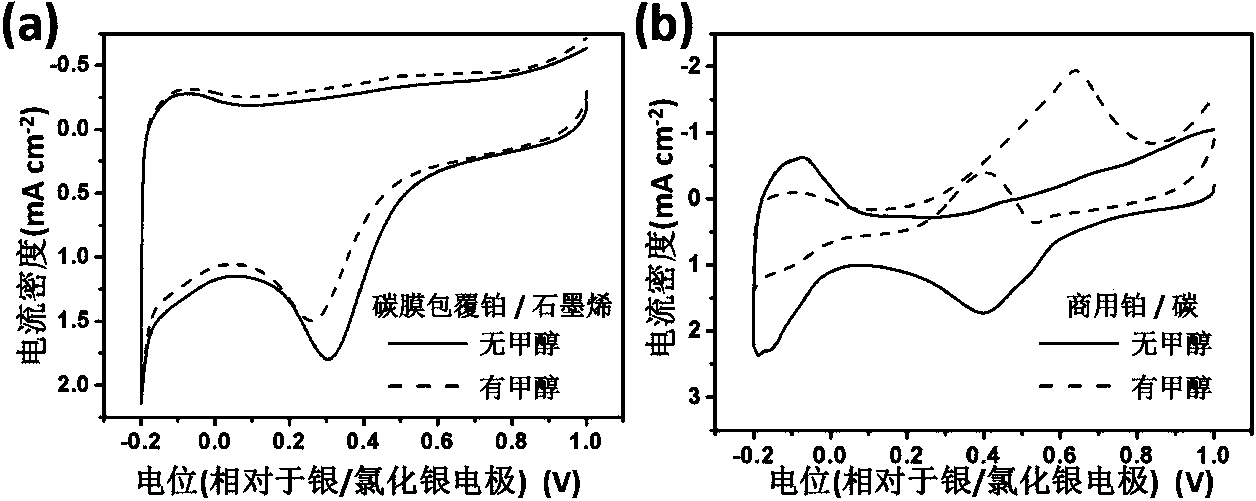

[0028] (1) Add 40 parts by mass of glucose, 1 part by mass of polyvinylpyrrolidone, and 0.5 parts by mass of chloroplatinic acid to 1000 parts by mass of 0.05wt% graphene oxide dispersion, stir magnetically for 15 minutes and ultrasonically for 20 minutes to obtain a uniform of the dispersion. The dispersion was put into a hydrothermal kettle and heated at 180°C for 8 hours. The black liquid obtained after hydrothermal treatment was successively washed with deionized water (8-10 times) and ethanol (at least 10 times) and centrifuged until the supernatant was colorless. The resulting platinum / graphene catalyst was freeze-dried to constant weight with a platinum loading of 7.4 wt%.

[0029] (2) Add platinum / graphene powder into a ceramic crucible and put it into a tube furnace (SGL-1200, Shanghai Daheng Optical and Precision Instrument Co., Ltd.), at a flow rate of 50 L h -1 In a nitrogen atmosphere, heated at 700 °C for 3 hours, with a heating rate of 10 °C min -1 , and natu...

Embodiment 2

[0031] (1) Add 1 mass part of polyvinylpyrrolidone and 0.5 mass part of chloroplatinic acid to 1000 mass parts of 0.05wt% graphene oxide dispersion, magnetically stir for 15 minutes and sonicate for 20 minutes to obtain a uniform dispersion. The dispersion was put into a hydrothermal kettle and heated at 180°C for 8 hours. The black liquid obtained after hydrothermal treatment was successively washed with deionized water (2-3 times) and ethanol (at least 2 times) and centrifuged until the supernatant was colorless. The resulting platinum / graphene catalyst was freeze-dried to constant weight with a platinum loading of 23.4 wt%.

[0032] (2) Add platinum / graphene powder into a ceramic crucible, put it into a tube furnace, and put it into a tube furnace at a flow rate of 50 L h -1 In a nitrogen atmosphere, heated at 700 °C for 3 hours, with a heating rate of 10 °C min -1 , and naturally cooled in a nitrogen atmosphere to obtain a platinum / graphene catalyst with a carbon coating...

Embodiment 3

[0034](1) Add 40 parts by mass of glucose, 20 parts by mass of polyvinylpyrrolidone, and 10 parts by mass of chloroplatinic acid to 20,000 parts by mass of 0.05wt% graphene oxide dispersion, stir magnetically for 15 minutes and ultrasonically for 20 minutes to obtain a uniform of the dispersion. The dispersion was put into a hydrothermal kettle and heated at 180°C for 3 hours. The black liquid obtained after hydrothermal treatment was successively washed with deionized water (3-5 times) and ethanol (at least 5 times) and centrifuged until the supernatant was colorless. The resulting platinum / graphene catalyst was freeze-dried to constant weight.

[0035] (2) Add platinum / graphene powder into a ceramic crucible, put it into a tube furnace, and put it into a tube furnace at a flow rate of 50 L h -1 In a nitrogen atmosphere, heated at 600 °C for 1 hour, with a heating rate of 10 °C min -1 , and naturally cooled under a nitrogen atmosphere during cooling, a platinum / graphene ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com