Anti-bypass type direct safety injection deflector and direct safety injection device

A direct, flow-type technology, applied in cooling devices, reactors, and reducing greenhouse gases, etc., can solve problems such as large thermal stress at the welding point, reduce the service life of safety injection nozzles, and sharp turns of safety injection water, so as to improve diversion Good diversion and guiding effect, solve the effect of poor anti-bypass flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

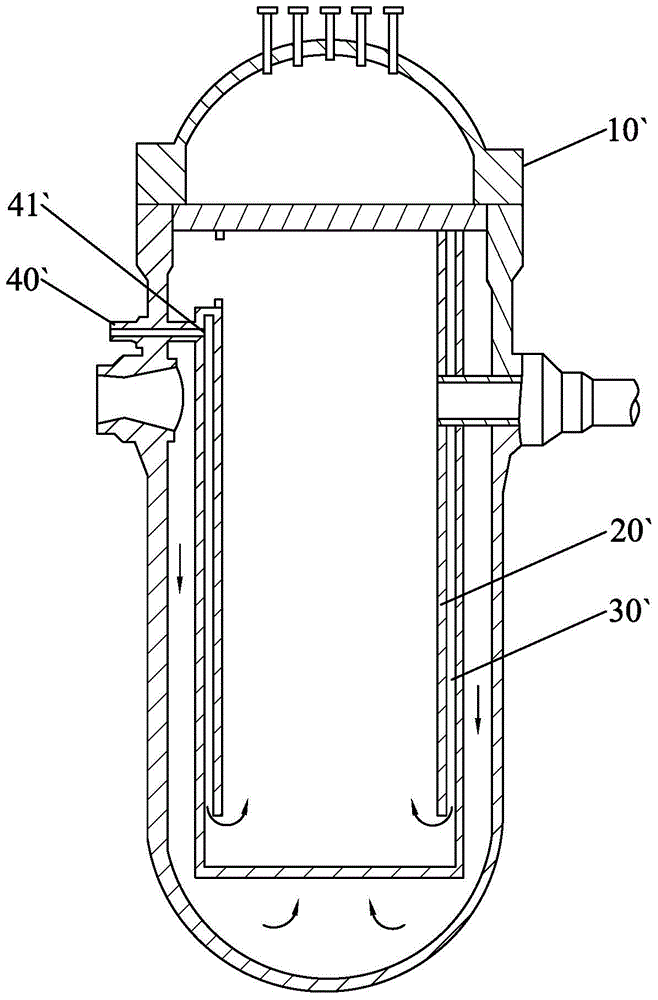

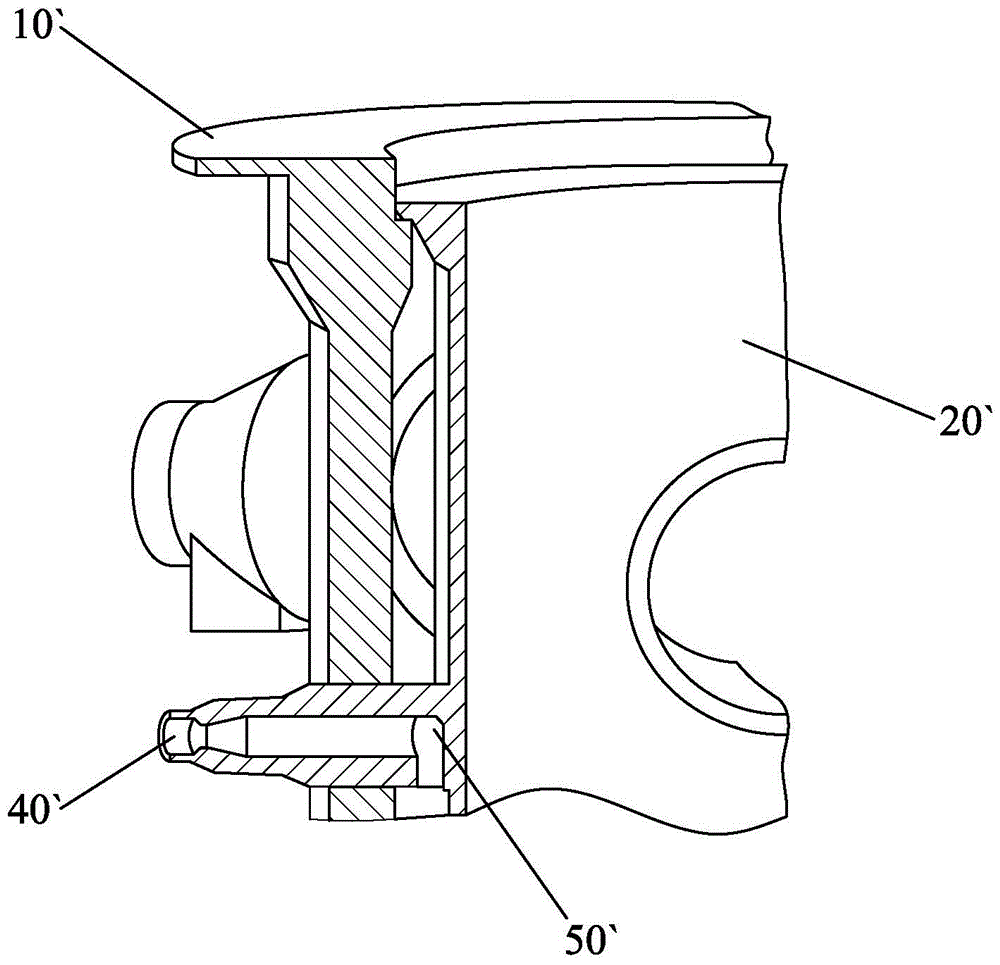

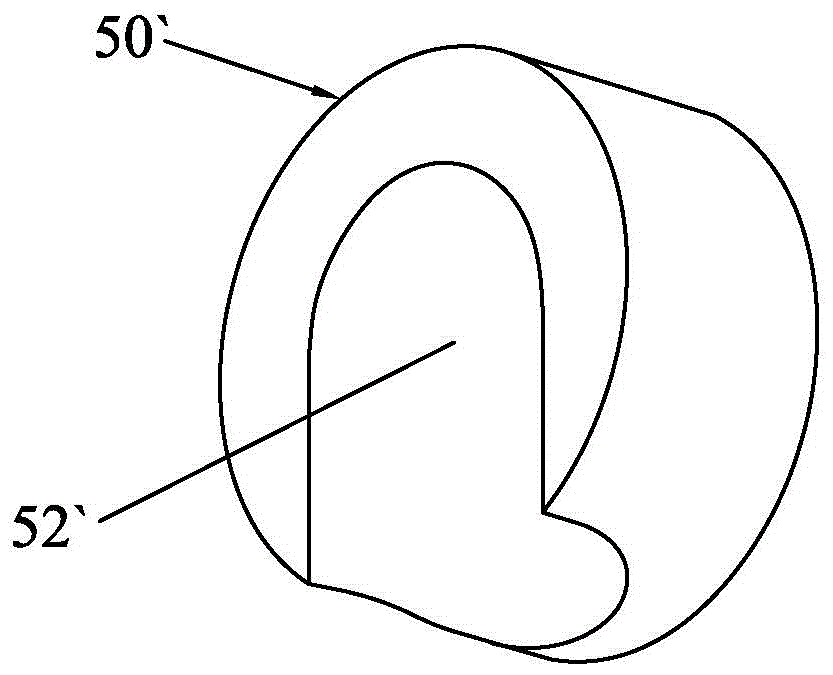

[0036] Such as Figure 5-Figure 9b As shown, the direct injection device 100 of the present invention includes a direct injection nozzle 40 and an anti-bypass type direct injection guide 50, and the anti-bypass type direct injection guide 50 and the direct injection tube The outlet 41 of the nozzle 40 is docked to guide the safe injection water, wherein the anti-bypass type direct injection guide 50 includes a hollow and downwardly bent guide tube body 51, and the guide tube The body has an inlet 52 and a downward outlet 53, the inlet 52 is connected to the outlet 41 of the direct injection nozzle 40, and the outlet 53 is in a flat structure, and the inlet The calibers from the outlet port 52 to the outlet port 53 gradually increase. Specifically, the diversion pipe body 51 of the present invention can use the direct sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com