High-temperature pressurization airflow solid particle erosive wear testing device

A solid particle and testing device technology, which is applied in the direction of testing wear resistance, etc., can solve the problems of difficult particle velocity measurement, inaccuracy, and unsuitable precise control of velocity and angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

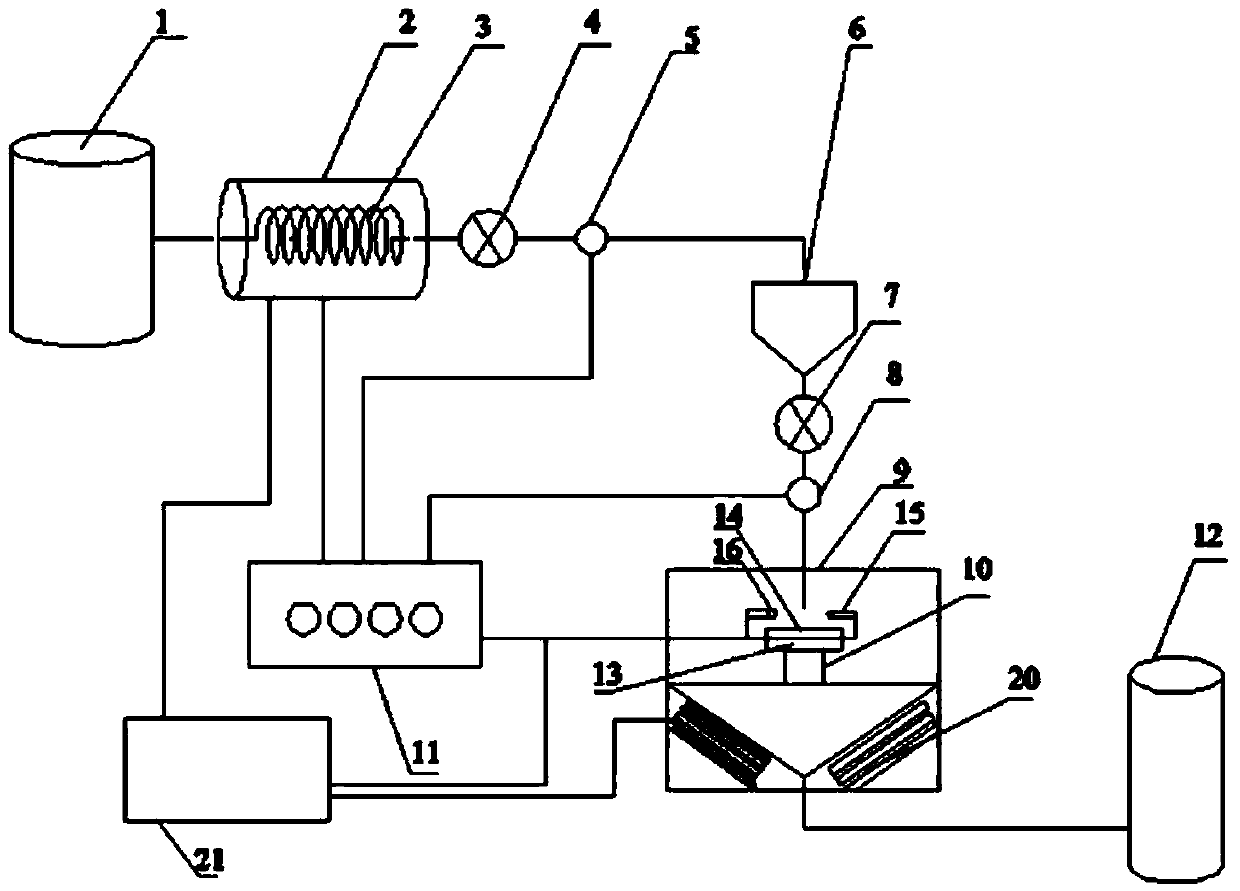

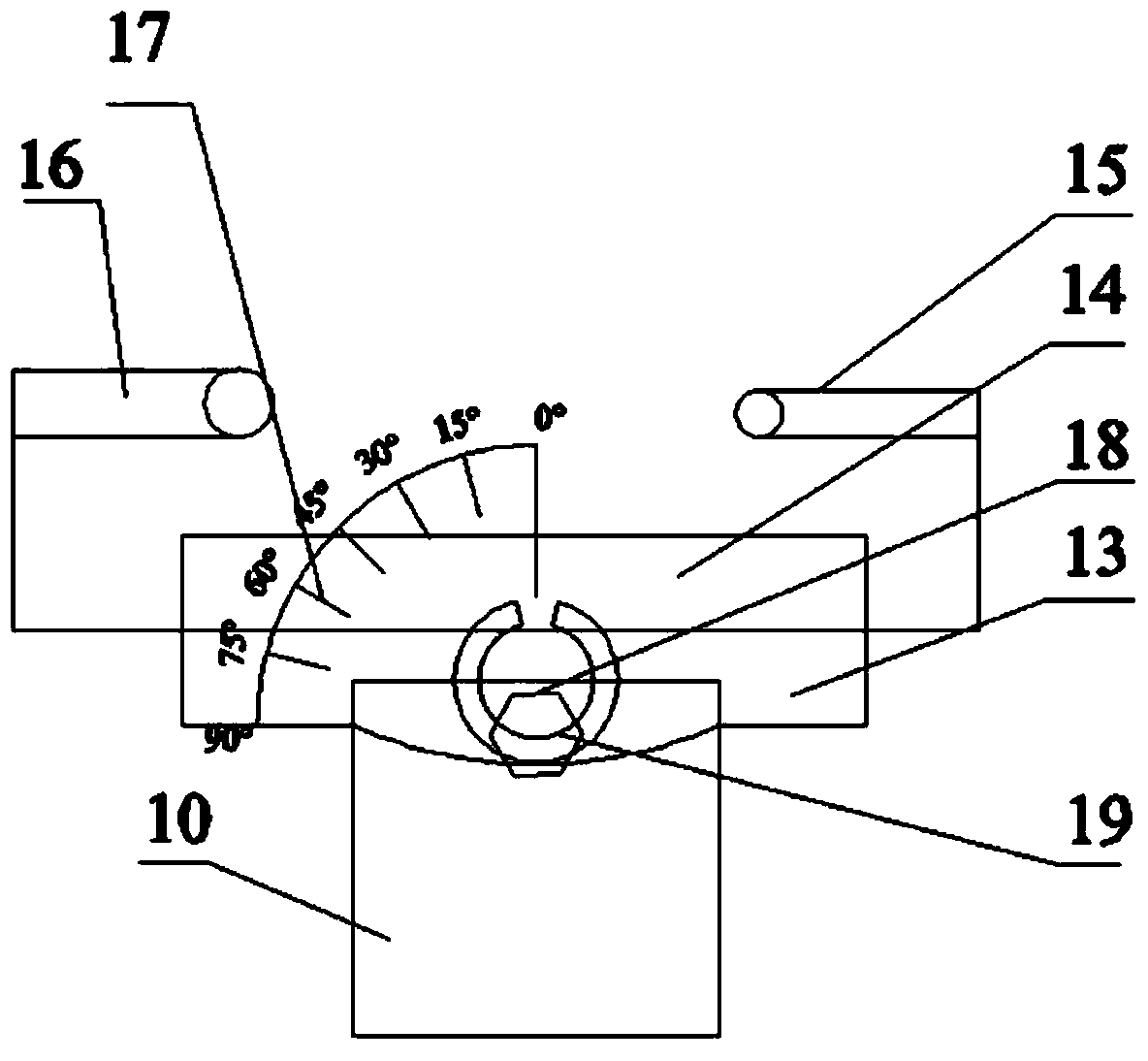

[0027] Such as figure 1 and figure 2 shown in figure 1 Among them, this embodiment includes an air compressor 1, a high-temperature air heater 2, a box body 9, an electronic high-temperature control valve 4, a gas flow meter 5, a solid particle feeder 6, a solid flow regulating valve 7, a solid flow meter 8, and a test Sample rack 10 and display 11. The gas generated by the air compressor 1 is heated by the high-temperature air heater 2. The gas outlet of the high-temperature air heater 2 is equipped with an electronic high-temperature control valve 4 and a gas flow meter 5 to adjust and display the gas supply pressure. The gas outlet of the high-temperature air heater 2 It is connected with the upper cavity of the closed solid particle feeder 6 . A solid flow regulating valve 7 and a solid flow meter 8 are provided at the outlet of the solid particle feeder 6 to control the amount of erosion. The solid particles complete the erosion process in the box 9. The circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com