Carbon-nitrogen-oxygen combined treatment process and device

A composite treatment and treatment device technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of high price of nitrided salt and oxide salt, single heat treatment technology, pollution of the environment, etc., and achieve the effect. Good, exhaust gas purification effect is good, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

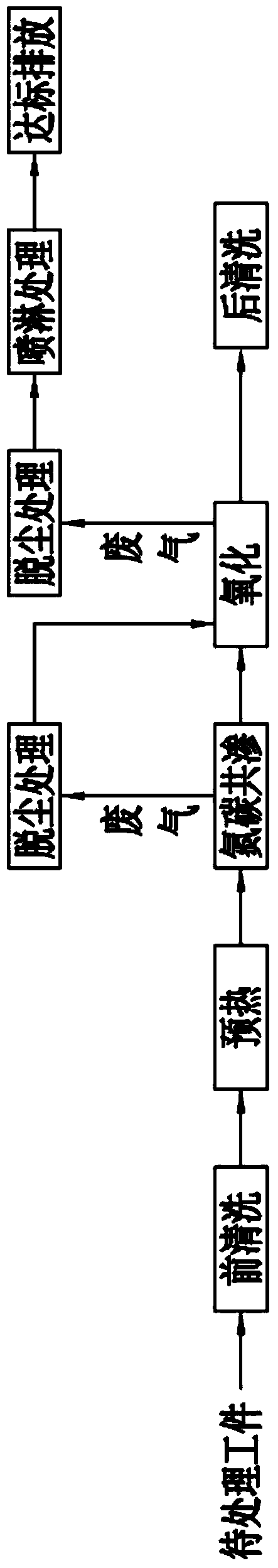

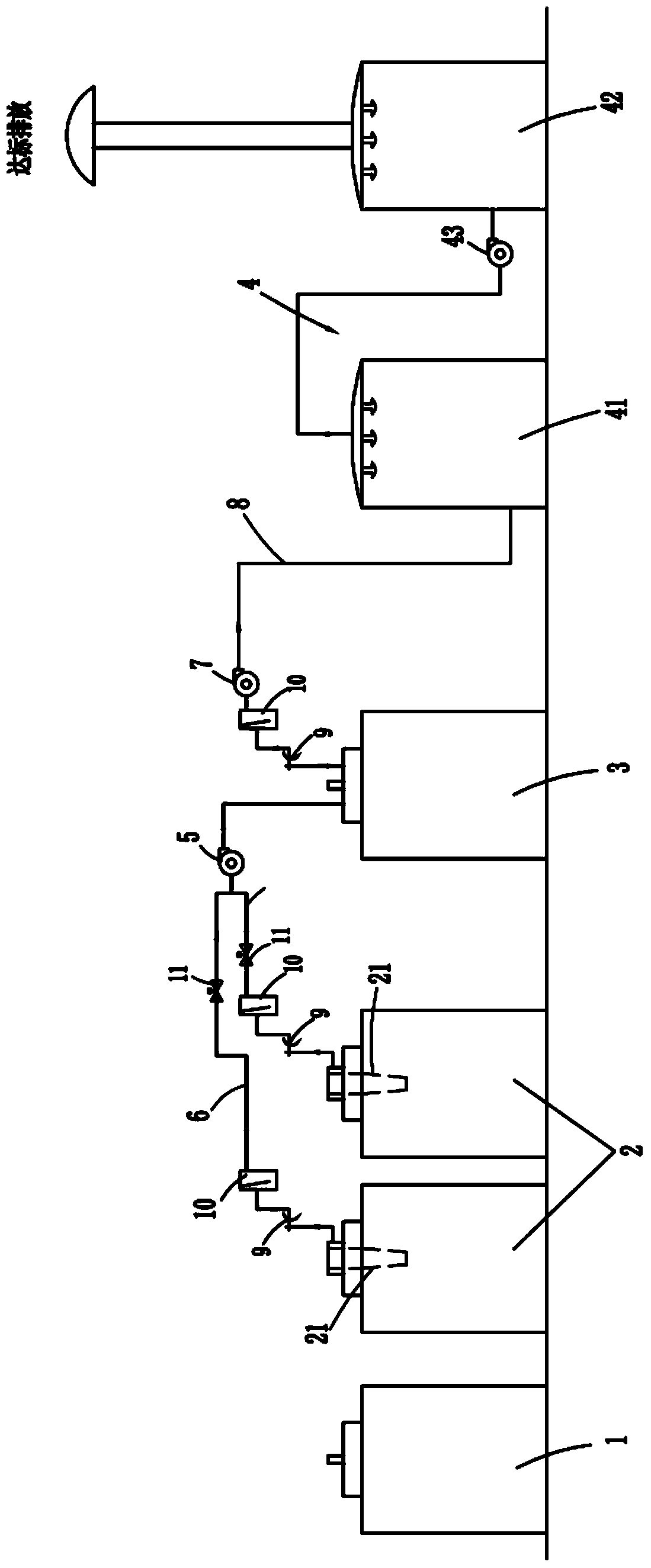

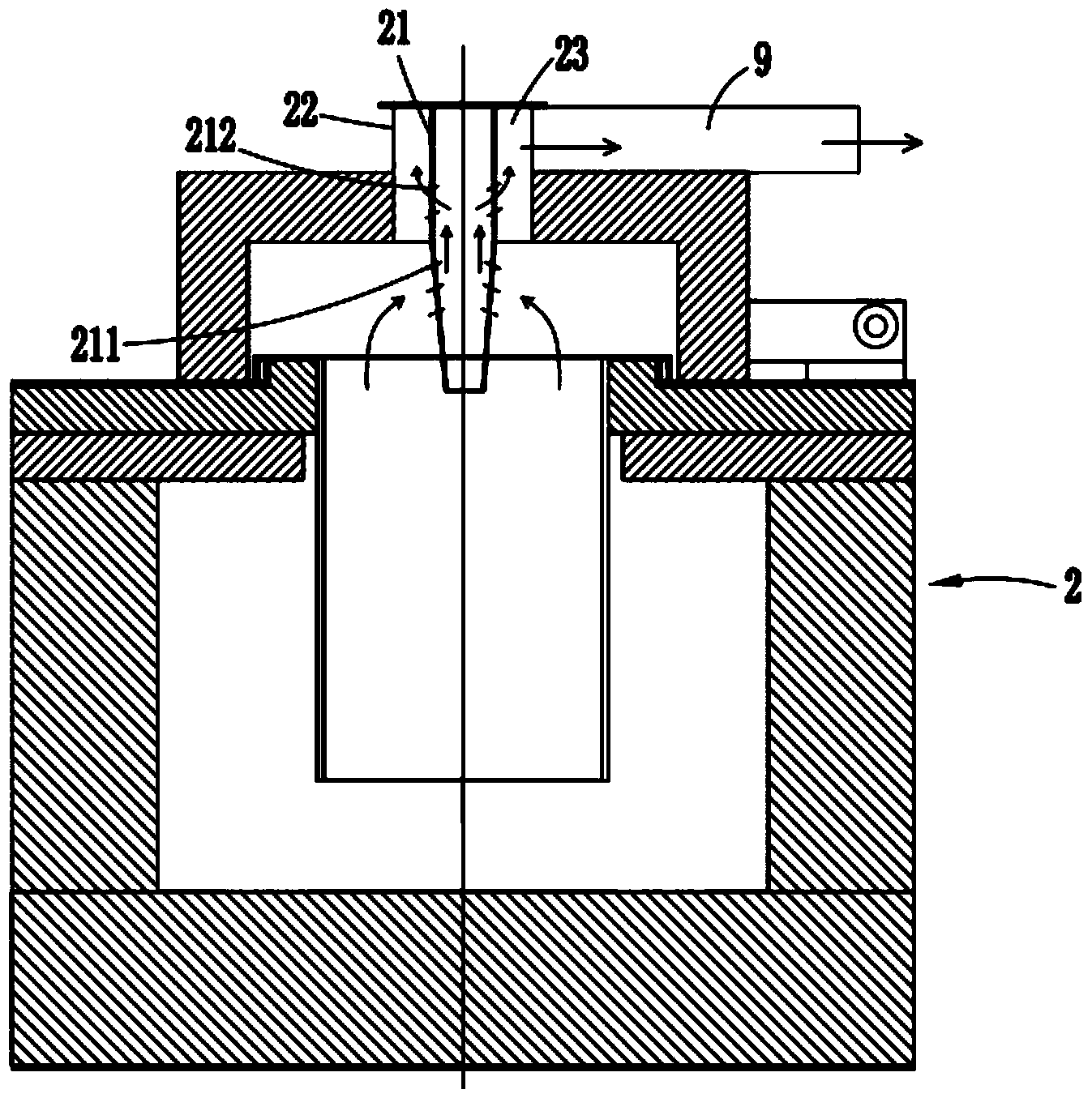

[0034] Such as figure 1 As shown, a nitrogen-carbon-oxygen compound treatment process includes pre-cleaning, preheating, nitrocarburizing, oxidation, post-cleaning and exhaust gas treatment. The workpiece after loading is first degreased by metal cleaning agent solution, washed with cold water and hot water After cleaning, carry out preheating treatment in the preheating furnace 1 with a temperature of 350°C to 400°C, and then hang it into a nitriding furnace 2 with a temperature of 400°C to 550°C for nitrocarburizing treatment. The base salt cyanate content is controlled in the range of 33% to 38%, and then enters the oxidation furnace 3 for oxidation treatment. The oxidation time is 10min to 60min, and then enters a hot water tank with a temperature of 70°C to 80°C for 10min to 20min. Afterwards, it is cooled and dried in the air. The waste gas treatment steps are: the first step: introducing the toxic gas in the nitriding furnace 2 into the oxidation furnace 3 for detoxific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com