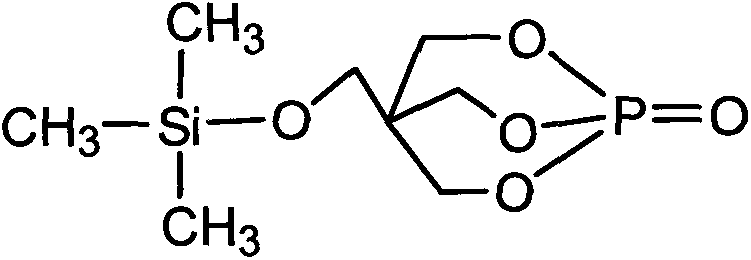

Caged flame-retardant char-forming agent trimethylsilicate pepa compound and preparation method thereof

A technology of trimethylsilicic acid and trimethylchlorosilane is applied in the field of cage-like flame retardant char-forming agent trimethyl silicic acid PEPA ester compound and its preparation, which can solve the problems of secondary combustion of materials and achieve charcoal formation. The effect of good performance, simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

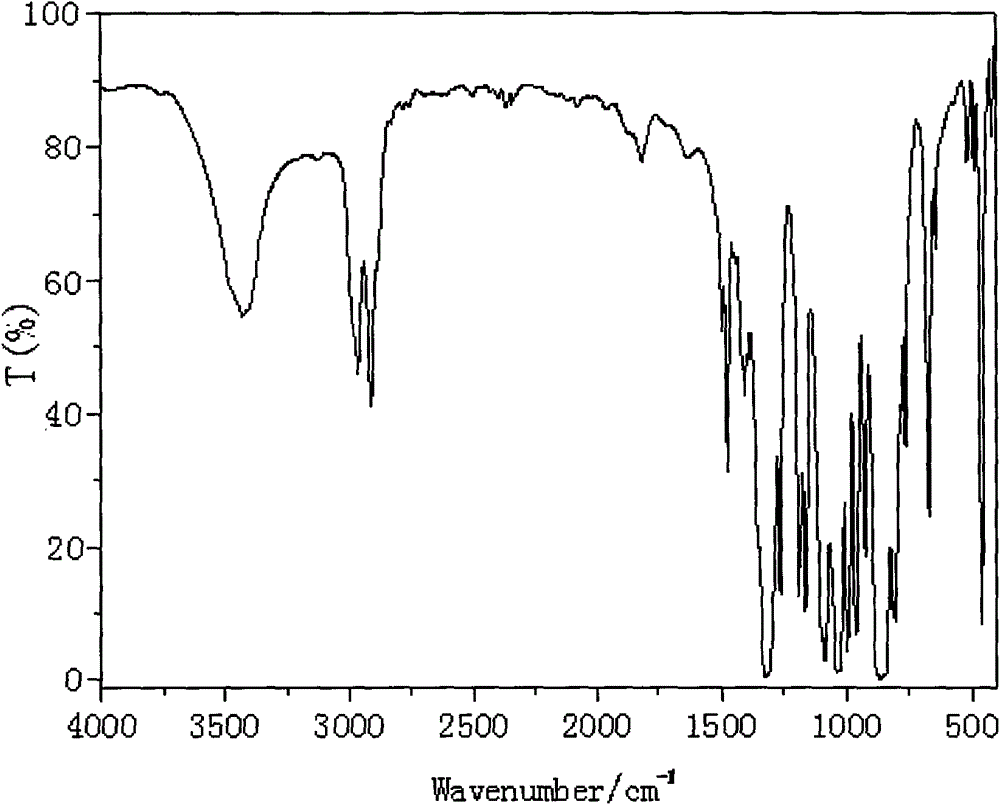

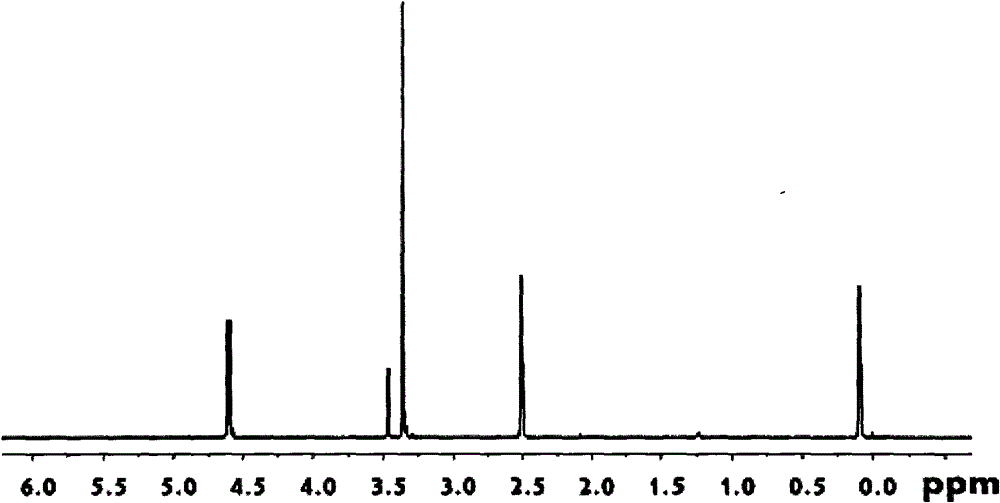

Image

Examples

Embodiment 1

[0028] Embodiment 1 is equipped with magnetic stirrer, thermometer and high-efficiency reflux condenser, and in the 100ml four-neck flask that drying tube is housed on the condenser upper mouth, replace the air in the bottle with nitrogen, 4.5g (0.025mol) Add PEPA and 30ml of ethylene glycol dimethyl ether into the four-necked flask, stir, and drop 2.716g (3.17ml, 0.025mol) trimethylchlorosilane into the four-necked flask at 50°C, and control the temperature during the dropping process. When the temperature is higher than 60°C, after dropping, raise the temperature to 85°C, and react for 10 hours. After the HCl gas is released, add 0.15 g of triethylamine, keep stirring for 1 hour, and detect the pH of the solution = 5-6 as the reaction end point. The solvent is recovered by distillation under reduced pressure, and the solid crude product is left in the retort, converted into a reflux device, and then added with 30ml of absolute ethanol, stirred and heated to dissolve, cooled, ...

Embodiment 2

[0029] Embodiment 2 is equipped with magnetic stirrer, thermometer and high-efficiency reflux condenser, and in the 100ml four-neck flask that drying tube is housed on the condenser, replace the air in the bottle with nitrogen, and 4.5g (0.025mol) Add PEPA and 20ml of acetonitrile into the four-necked flask, stir, and drop 2.99g (3.48ml, 0.0275mol) trimethylchlorosilane into the four-necked flask at 50°C. After dropping, raise the temperature to 80°C and react for 11 hours. After the HCl gas is released, add 0.2 g of pyridine and keep stirring for 1 hour. The pH of the solution is detected to be 5-6 as the reaction end point. The solvent is recovered by distillation under reduced pressure, and the solid crude product is left in the retort, converted into a reflux device, and then added with 30ml of absolute ethanol, stirred and heated to dissolve, cooled, and the product is fully crystallized, filtered, and dried to obtain a cage The flame retardant char-forming agent PEPA tri...

Embodiment 3

[0030] Embodiment 3 is equipped with magnetic stirrer, thermometer and high-efficiency reflux condensation tube, and in the 100ml four-neck flask that drying tube is housed on the top of condensation tube, replace the air in the bottle with nitrogen, and 4.5g (0.025mol) Add PEPA and 50ml of dioxane into the four-necked flask, stir, and drop 3.26g (3.80ml, 0.03mol) trimethylchlorosilane into the four-necked flask at 50°C, the dropping process controls the temperature not higher than 60°C, after dripping, raise the temperature to 100°C, react for 8 hours, after the HCl gas is released, add 0.25g pyridine, keep stirring for 1 hour, and detect the pH of the solution = 5-6 as the reaction end point. The solvent is recovered by distillation under reduced pressure, and the solid crude product is left in the retort, converted into a reflux device, and then added with 30ml of absolute ethanol, stirred and heated to dissolve, cooled, and the product is fully crystallized, filtered, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com