YAG transparent ceramic for white light LED lamps and preparation method thereof

A technology of transparent ceramics and LED lamps, which is applied in the field of transparent ceramics, YAG transparent ceramic materials for white LEDs and its preparation, and can solve the problems of difficult control of thickness, high preparation temperature, and short life of white LEDs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

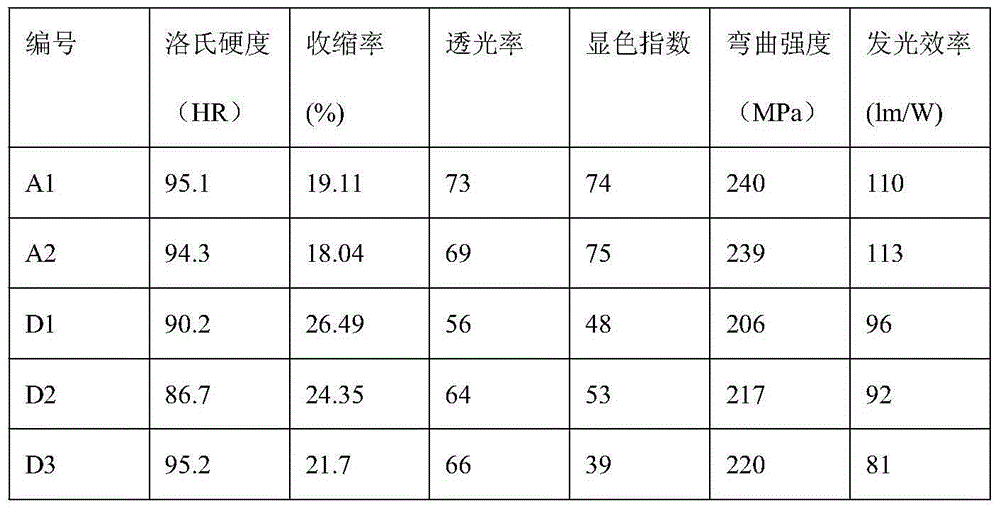

Embodiment 1

[0029] The mass composition of transparent ceramics is: Al 2 o 3 280 copies, Y 2 o 3 360 parts, SiO 2 65 parts, CeO 2 20 copies, PR 2 o 3 10 parts, Eu 2 o 3 5 copies, Lu 2 o 3 4 parts, LiF 2 parts, B 2 o 3 5 parts, 5 parts of SiC, 1 part of CaO0. Pre-mix the above raw materials, put them into a ball mill, add 500ml of absolute ethanol, then ball mill for 10 hours, dry in an oven at 100°C, and pass through a 600-mesh sieve after grinding. Then the plain embryo is pressed under 80MPa pressure, and then the rough embryo is placed in the crucible. Heating to 1250°C with a heating rate of 20°C / min, keeping it warm for 7 hours, continuing to heat up to 1520°C at a rate of 10°C / min and keeping it warm for 12 hours, then cooling naturally. Finally, the fired transparent ceramics are ground and polished to obtain a transparent ceramic product A1.

Embodiment 2

[0031] The mass composition of transparent ceramics is: Al 2 o 3260 copies, Y 2 o 3 320 parts, SiO 2 70 parts, CeO 2 15 copies, PR 2 o 3 5 parts, Eu 2 o 3 2 copies, Lu 2 o 3 2 parts, LiF 1 part, B 2 o 3 3 parts, SiC 3 parts, CaO 0.5 parts. Pre-mix the above raw materials, put them into a ball mill, add 500ml of absolute ethanol, then ball mill for 10 hours, dry in an oven at 100°C, and pass through a 600-mesh sieve after grinding. Then the plain embryo is pressed under 100MPa pressure, and then the rough embryo is placed in the crucible. Heating to 1300°C with a heating rate of 20°C / min, keeping it warm for 10 hours, continuing to heat up to 1580°C at a rate of 10°C / min and keeping it warm for 15 hours, then cooling naturally. Finally, the fired transparent ceramics are ground and polished to obtain a transparent ceramic product A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com