Wet-process rare earth smelting high ammonia-nitrogen wastewater resource utilization method and device

A high-ammonia-nitrogen, resource-based technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low enthusiasm for enterprise operation, incomplete pretreatment, and limited processing capacity and other issues, to achieve significant energy saving and environmental protection effects, facilitate multi-stage heat exchange, and realize energy utilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

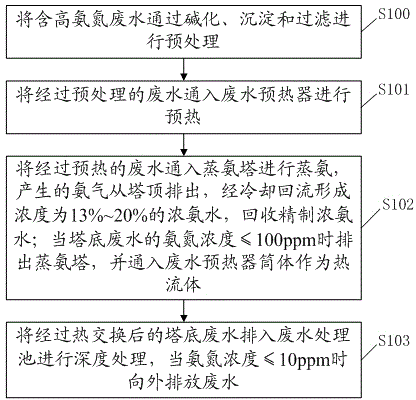

Method used

Image

Examples

Embodiment approach

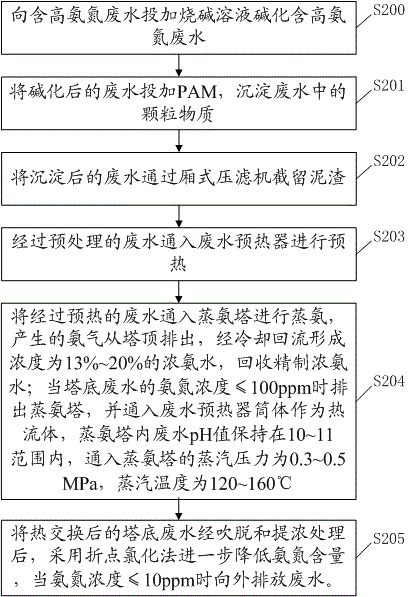

[0051] Such as figure 2 As mentioned above, the present invention provides a preferred embodiment of a method for resource utilization of high ammonia nitrogen wastewater from wet rare earth smelting, including the following steps:

[0052] S200 Add caustic soda solution to the wastewater containing high ammonia nitrogen to alkalize the wastewater containing high ammonia nitrogen.

[0053] Through experiments, the percentage of free ammonia in total ammonia in different pH solutions is shown in Table 1. It can be seen that the stronger the alkalinity of wastewater, the more conducive to the separation of ammonia water, but to achieve a water environment with pH = 12, a larger The input, when the wastewater pH=10~11, it will achieve good results. Therefore, quantitatively add caustic soda solution before entering the ammonia distillation tower, and control the pH of the wastewater in the ammonia distillation tower to be 10~11, so that the free ammonia in the solution accounts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com