Mite killing machine

A body and rolling brush technology, which is applied in the device, application, animal husbandry and other directions of catching or killing insects, can solve the problems of increasing the size of the mite removal machine, poor penetration, unable to effectively kill bacteria and mites, etc. Achieve the effect of prolonging the time of removing mites, strengthening the effect of removing mites, and facilitating replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

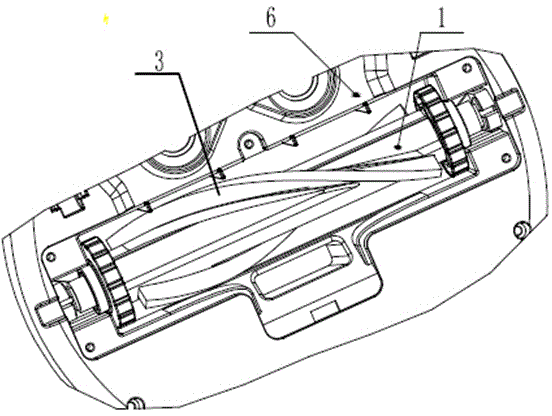

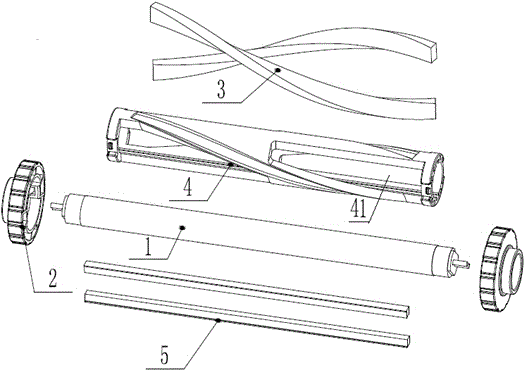

[0028] The invention discloses a mite removing machine, such as Figure 1 to Figure 4 As shown, it is the same as a general mite removing machine, including a casing 6 and a cylindrical roller brush body 4 arranged in the casing 6 and an ultraviolet lamp 1 for removing mite and sterilizing. The difference is that the rolling brush body 4 is a hollow tubular body, the ultraviolet lamp tube 1 is penetrated in the hollow rolling brush body 4, and the rolling brush body 4 is provided with a light-transmitting hole for the ultraviolet light tube to transmit light. 41. Preferably, the roller brush body 4 is coaxial with the ultraviolet lamp 1 .

[0029] Specifically, the two ends of the roller brush body 4 are fixed on the roller 2 pivotally arranged with the casing, and the two ends of the ultraviolet lamp 1 extend out of the roller brush body 4 and the roller 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com