Fluorescent layer, preparation method thereof, and application of fluorescent layer in nuclear batteries

A fluorescent layer and nuclear battery technology, applied in the field of fluorescent layer, can solve problems such as material lattice damage, achieve the effects of improved adaptability, increased spectral acceptance range, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

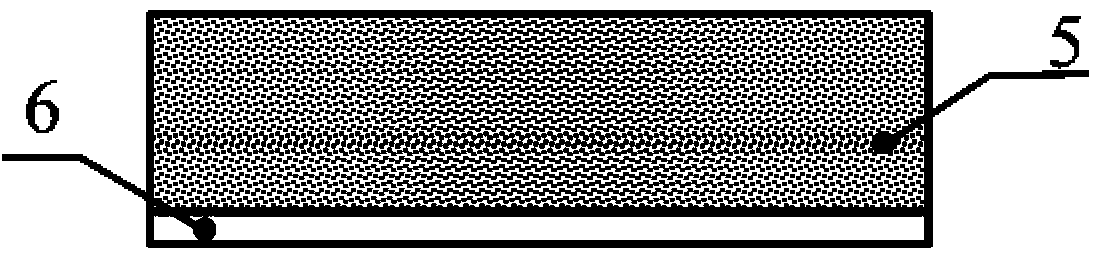

[0049] Step 1. Select a size of 30mm*30mm*0.5mm, a light transmittance of 95%, and a 1000°C resistant quartz glass sheet as the phosphor layer substrate 6, and clean it for many times with deionized water and alcohol;

[0050] Step 2: Use physical sedimentation technology to deposit a layer of ZnS:Cu fluorescent layer 5 with a thickness of 70μm on the substrate 6, and place the deposited sample at 250°C for 30 minutes and allow it to cool naturally to room temperature It can be taken out to complete the preparation of the radiation-induced fluorescent layer, and the whole preparation environment is normal pressure;

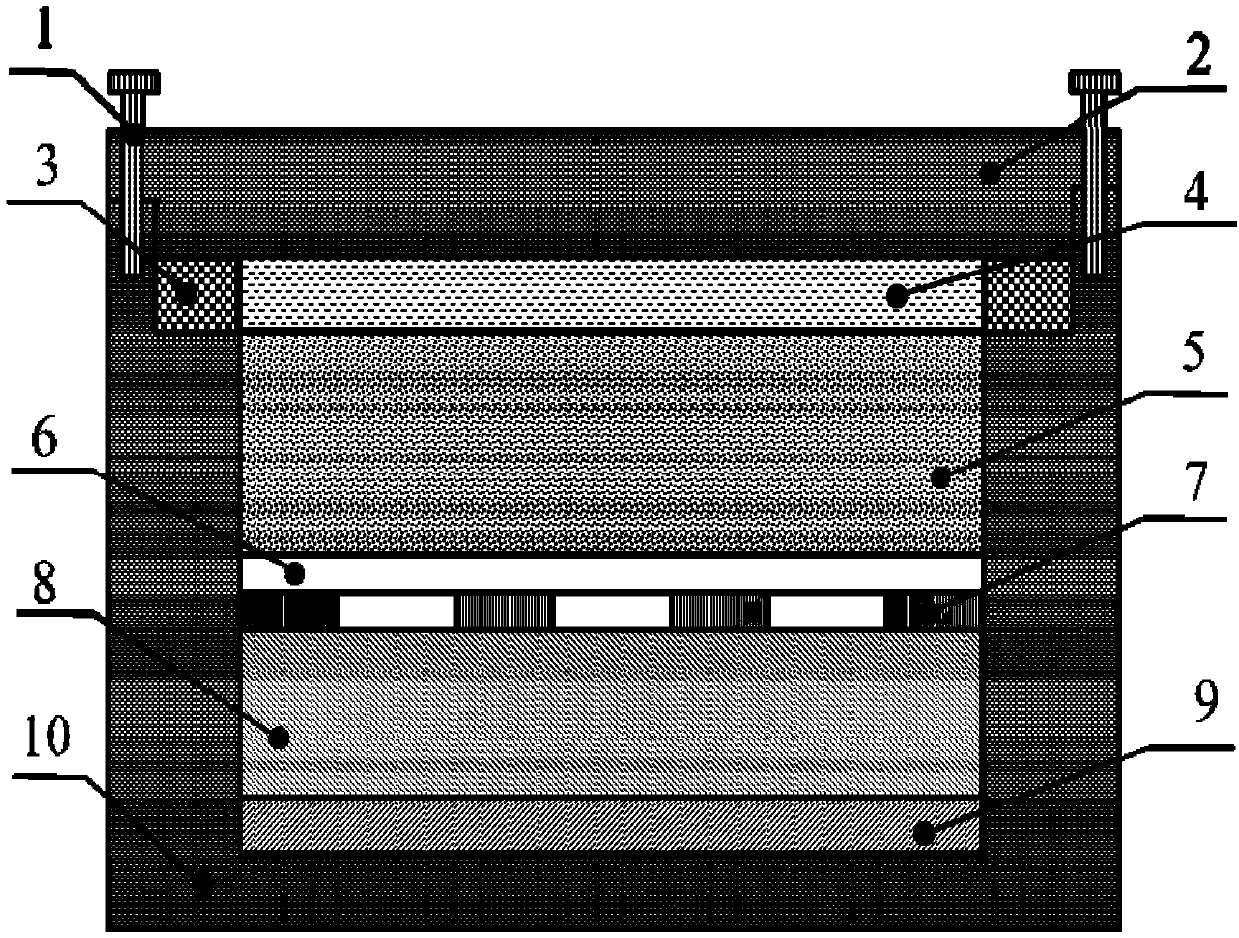

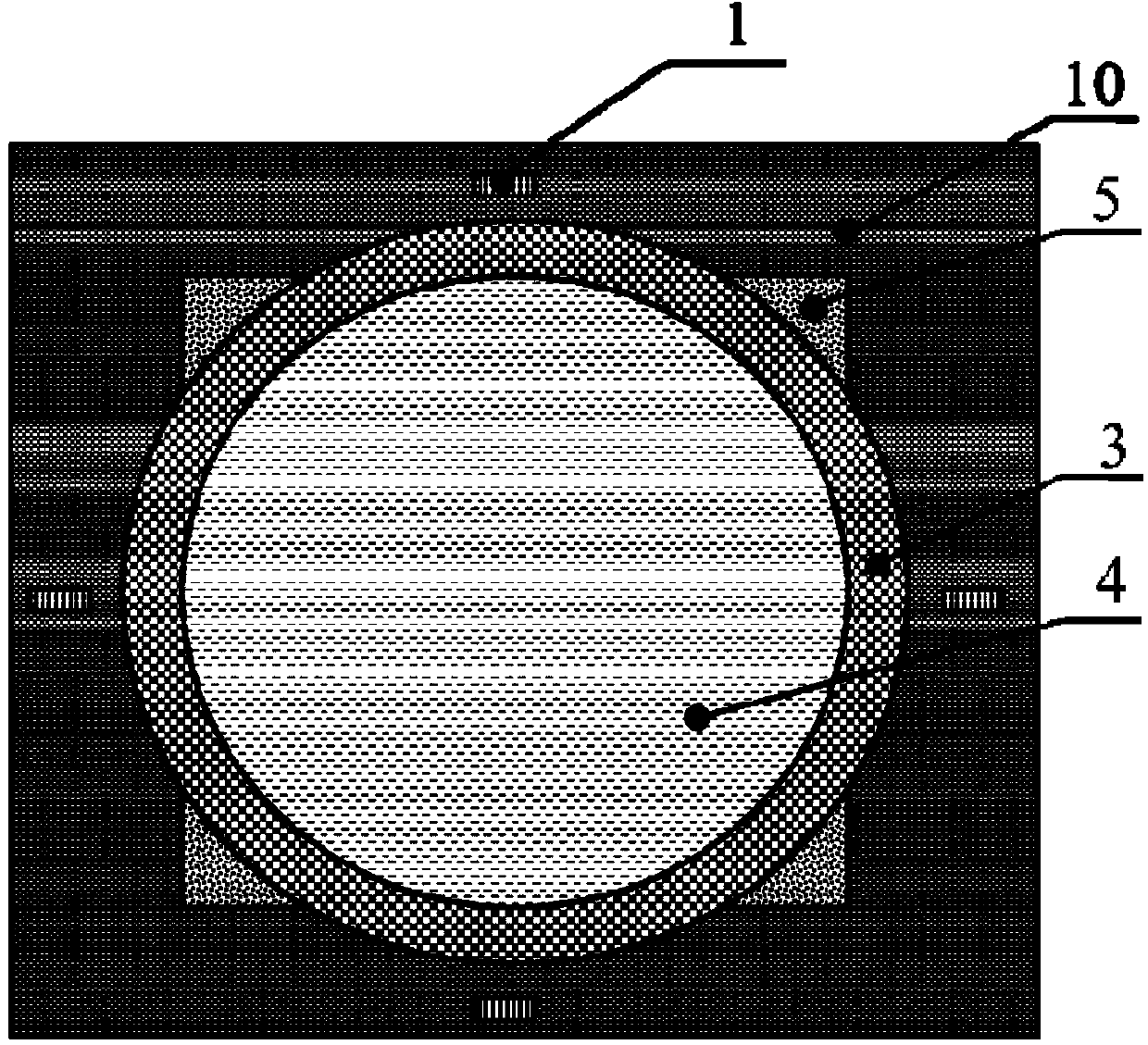

[0051] Step 3. Prepare the outer structure of the nuclear battery. The supporting device 10 is made of alumina ceramic material, rectangular parallelepiped shape, 30mm high, a rectangle with a bottom surface of 40mm*35mm, a hollow inside, and a rectangular parallelepiped shape with a depth of 20mm and a bottom surface of 35mm *30mm rectangle, cut out a circular hole wi...

Embodiment 2

[0057] This example is the same as Example 1 except for the following differences.

[0058] Step 1. Select a size of 30mm*30mm*0.3mm, a light transmittance of 95%, and a 1000℃ resistant quartz glass sheet as the phosphor layer substrate 6, and wash it with deionized water and alcohol for many times;

[0059] Step 2: Use physical sedimentation technology to deposit a layer of ZnS:Cu fluorescent layer 5 with a thickness of 90 μm on the substrate 6, place the deposited sample at 250°C for 30 minutes, and let it cool to room temperature naturally It can be taken out to complete the preparation of the fluorescent layer, and the whole preparation environment is normal pressure;

[0060] Step 5. Load a fluorescent layer composed of a ZnS:Cu fluorescent layer and a quartz glass substrate on top of the semiconductor layer, and continue to load a layer of plated radioactive metal promethium-147 and non-radioactive metal promethium on top of it, with a thickness of about 3mm ;

[0061] Step 6: ...

Embodiment 3

[0064] This example is the same as Example 1 except for the following differences.

[0065] Step 2: Use physical sedimentation technology to deposit a layer of Y with a thickness of 91 μm on the substrate 6 2 O 2 S: Eu fluorescent layer 5. Place the deposited sample at 250°C for 30 minutes and dry it, and then take it out when it is naturally cooled to room temperature. The preparation of the radiation-induced fluorescent layer is completed, and the entire preparation environment is normal pressure;

[0066] Step 5. Load Y 2 O 2 S: The radiation-induced fluorescent layer composed of Eu fluorescent layer and quartz glass substrate, on which a layer of plated radioactive metal promethium-147 and non-radioactive metal promethium is continuously loaded, the thickness is about 3mm;

[0067] Step 6. Load a sealing cover on the entire peripheral structure, encapsulate the cells of the battery, and fix the entire battery with connecting devices such as screws to complete the preparation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com