Fastening bolt for shear wall formwork

A technology for fastening bolts and shear walls, which is applied to the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc. Slurry and other problems, to avoid the unevenness of the outer wall, improve the appearance quality, and operate safely and reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

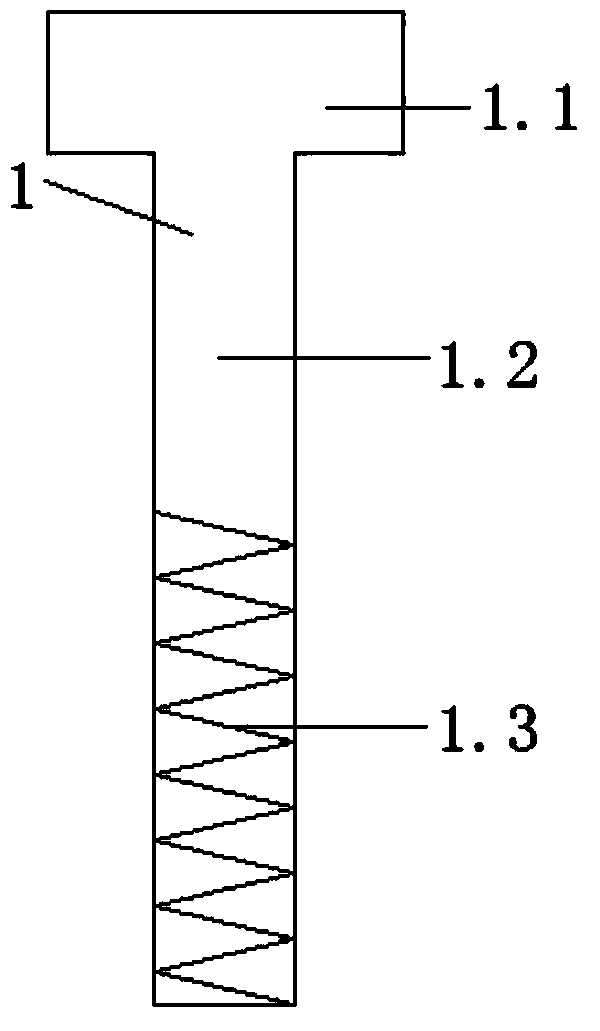

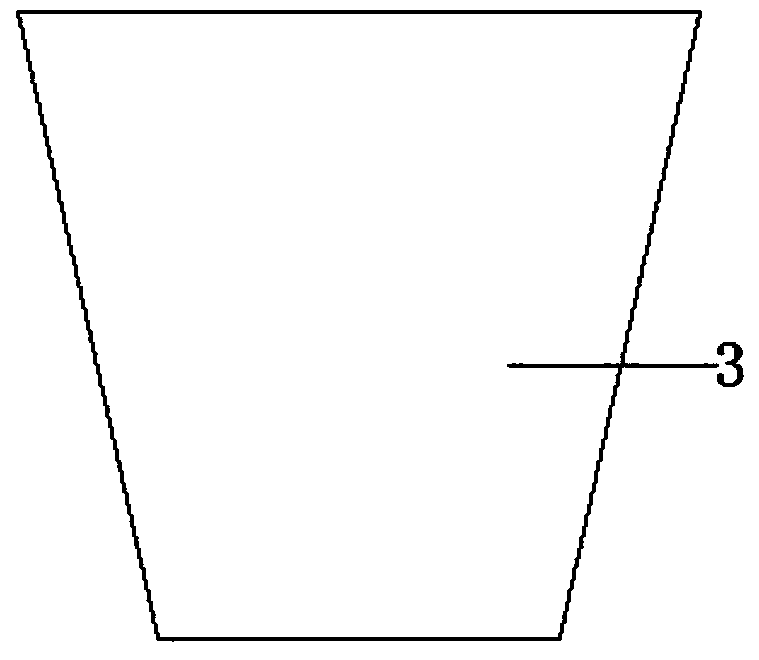

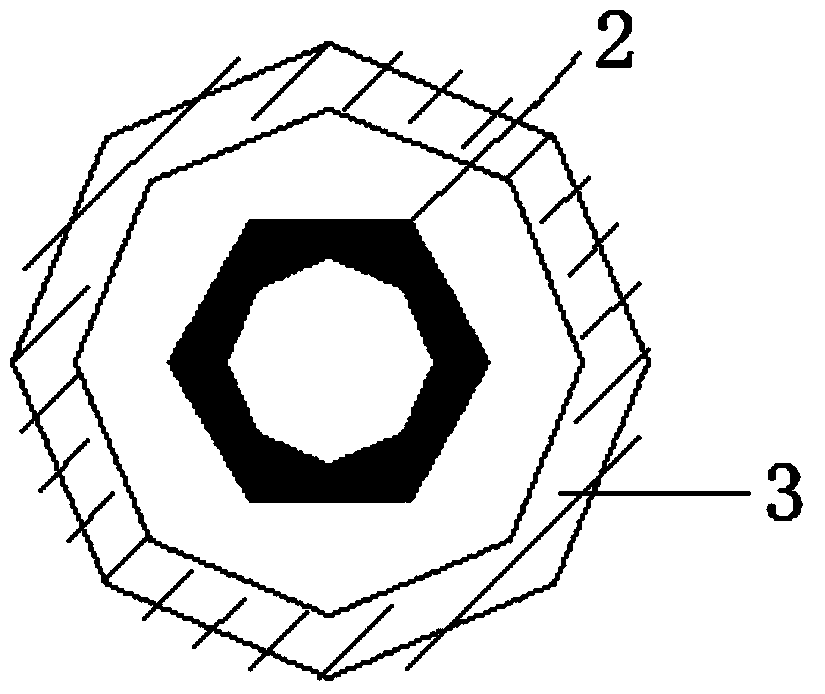

[0023] Such as Figure 1-4 As shown, a fastening bolt for a shear wall formwork described in the embodiment of the present invention includes a pre-embedded fastening bolt 1, a nut 2, a reinforcing connecting rod 4 and a mountain-shaped clip 5, and the pre-embedded fastening bolt 1 It includes a head 1.1 and a rod body 1.2, the lower end of the rod body 1.2 is provided with an external thread 1.3; the nut 2 is provided with an internal thread, the internal thread matches the external thread 1.3, and the nut 2 is provided with a nut sleeve outside 3. Both ends of the reinforced connecting rod 4 are provided with external threads 4.1, and the internal threads of the nut 2 match the external threads 4.1 of the reinforced connecting rod 4; the middle of the mountain-shaped clamp 5 is provided with a screw hole 5.1, so that The size of the screw hole 5.1 matches the external thread 4.1 of the reinforced connecting rod 4.

[0024] The width of the shank 1.2 of the pre-embedded fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com