Lug bending structure and battery cell reshaping device with lug bending structure

A reshaping device and a technology for tabs, which are applied in electrode manufacturing, electrolyte storage battery manufacturing, non-aqueous electrolyte storage batteries, etc., can solve the problems of inconsistent tab inversion, increased internal resistance, poor flatness, etc., and prevent tabs from falling. The effect of inconsistent direction, reduced internal resistance, and low overcurrent temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described below based on examples, but the present invention is not limited to these examples.

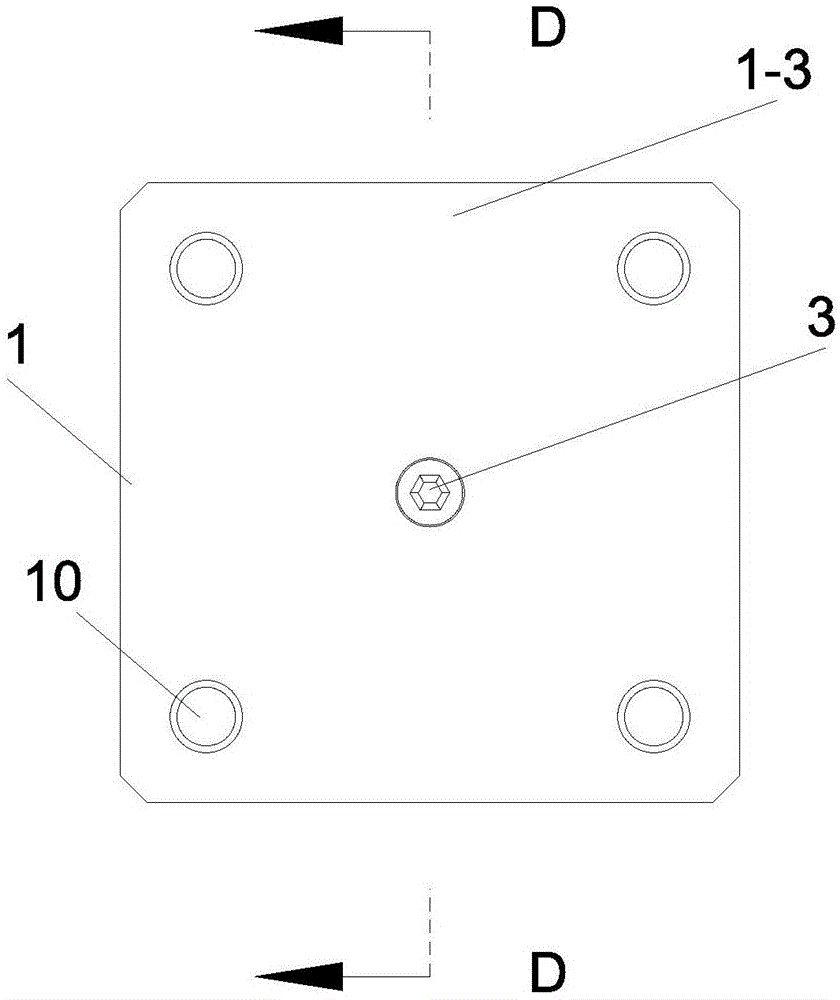

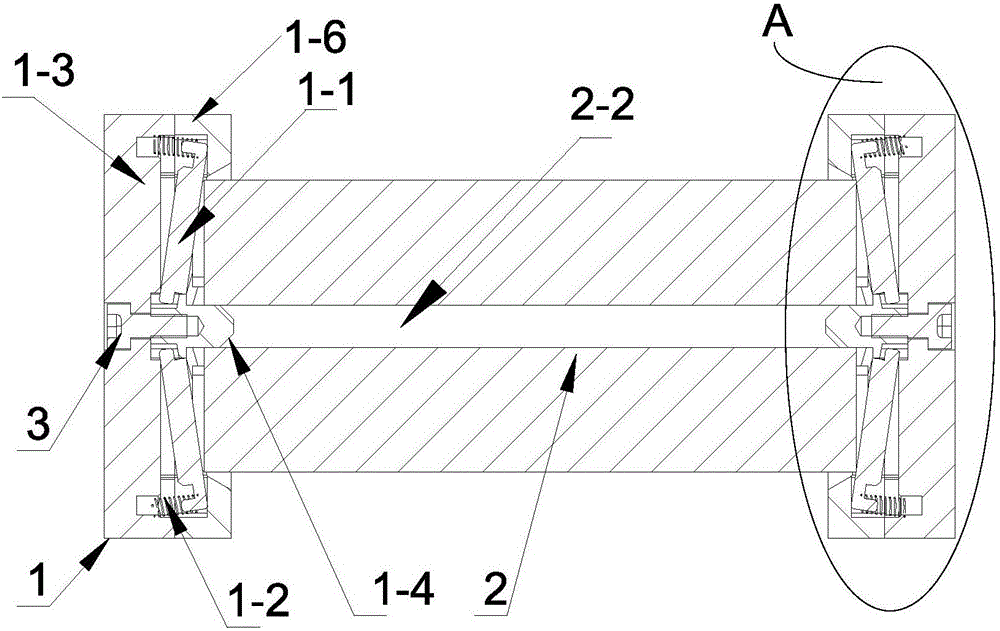

[0035] Such as Figure 1-3 As shown, the present invention provides a cell shaping device, which includes two sets of lug bending structures 1 and a first driver (not shown in the figure, preferably a cylinder), and the cells 2 that need to be shaped are arranged in the two groups. Among the tab bending structures 1, the tab bending structure 1 includes extruding parts, and the first driver drives two sets of tab bending structures 1 to move, so that the extruding parts bend the tabs at both ends of the battery cell 2 . The extruding surface of the existing extruding part is arranged parallel to the end surface of the electric core 2. When extruding, the extruding surface is simultaneously extruded with the end surface of the electric core 2, and the direction of the tab on the end surface of the electric core 2 is different. Certainly, therefore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com