Ultrasonic roll welding stand

An ultrasonic and seam welding machine technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of lack of welding method of solar panels, insufficient voltage, lead wires and welding points easily broken or falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe in detail the structure, features and effects of the present invention, hereby give the following two preferred embodiments and describe them as follows in conjunction with the drawings, wherein:

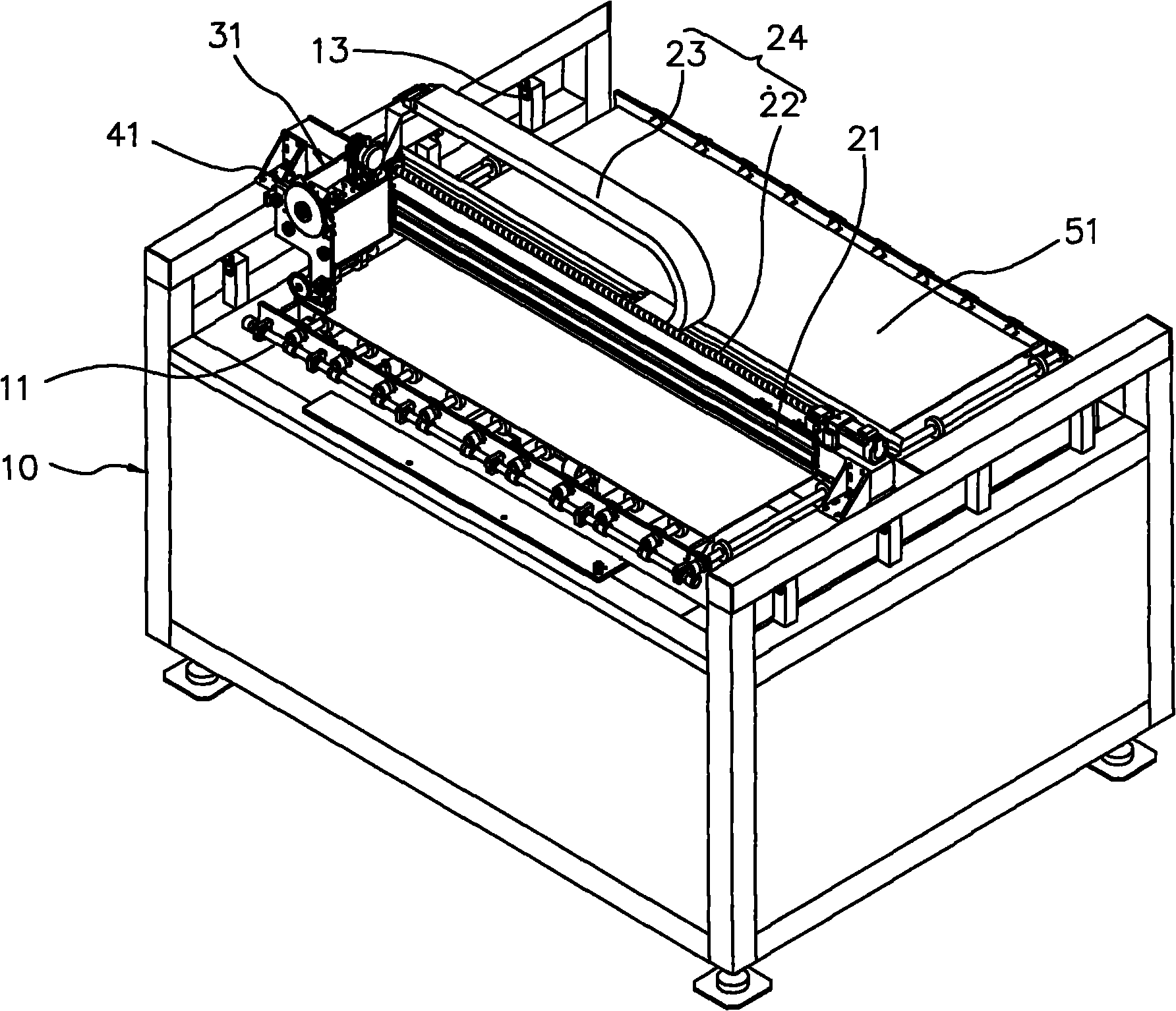

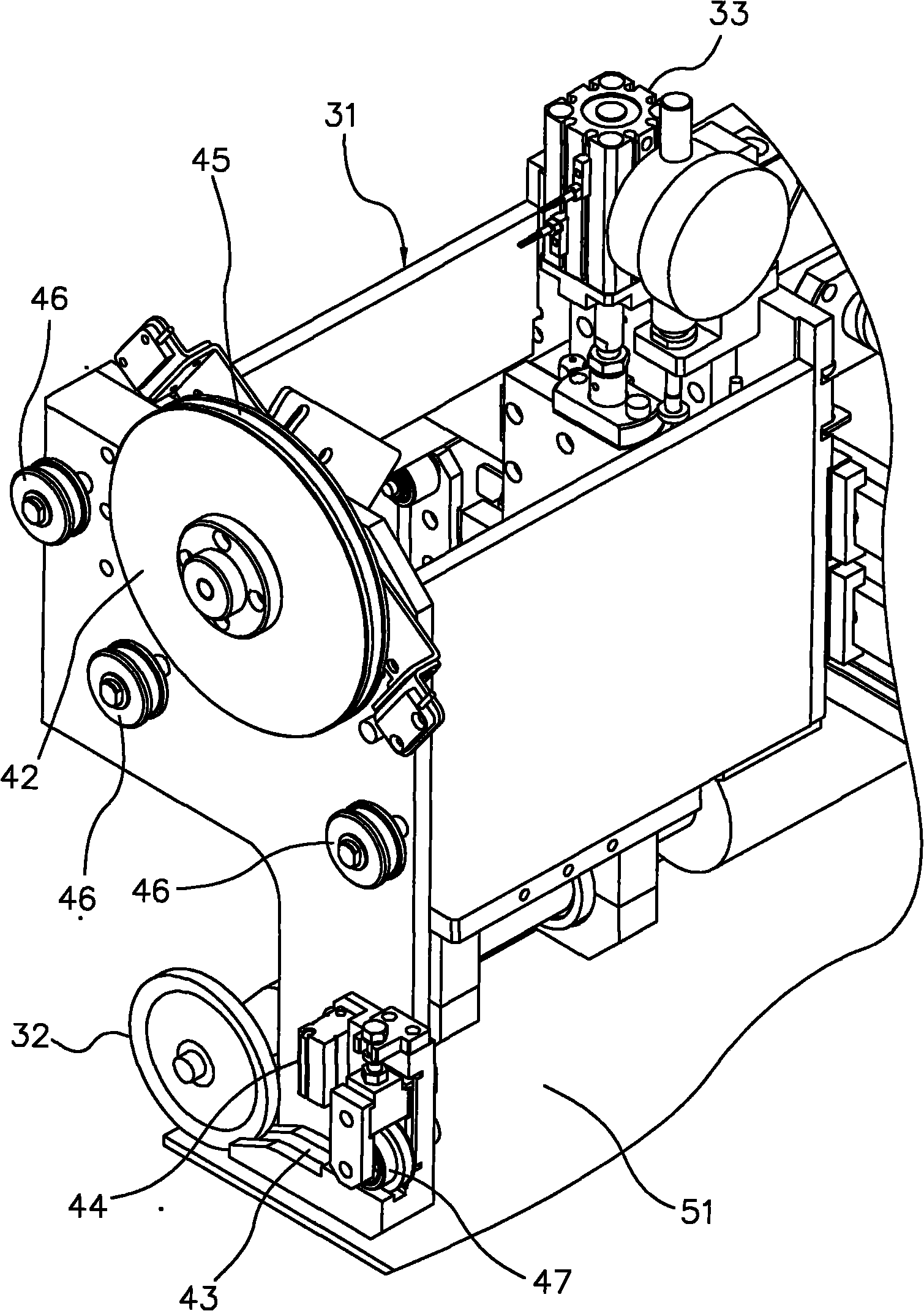

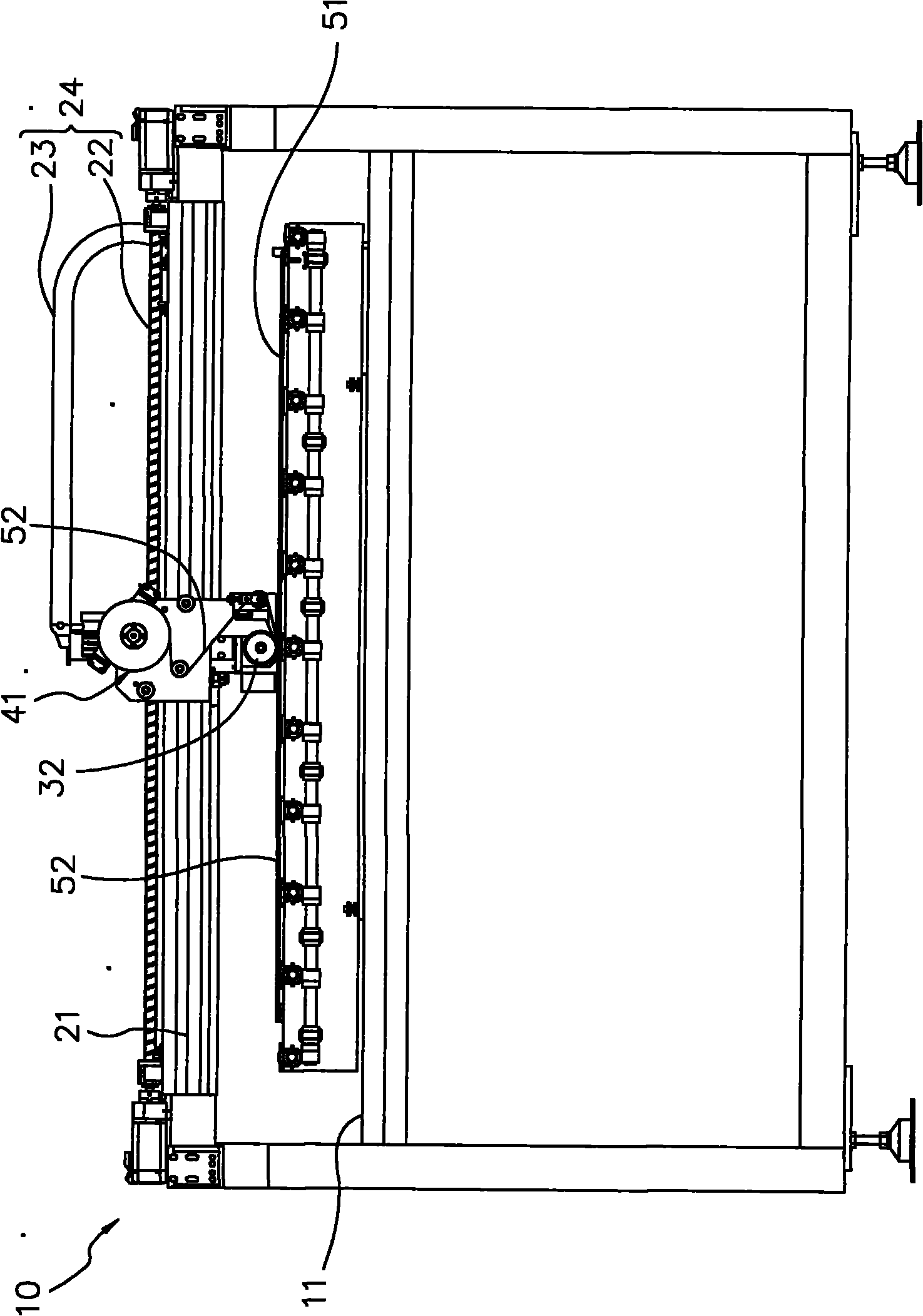

[0014] see figure 1 as well as figure 2 , an ultrasonic seam welding machine 10 provided by the first preferred embodiment of the present invention, the machine includes a platform 11 , a carrier arm 21 , an ultrasonic seam welding device 31 and a metal strip supplier 41 .

[0015] The platform 11 is elongated, the short axis of the platform 11 is parallel to the X axis, and the long axis of the platform 11 is parallel to the Y axis; Separated by a predetermined distance, the loading arm 21 is provided with a screw group 24, the screw group 24 includes a screw 22 and a slider 23, the screw 22 is parallel to the Y axis and is arranged on the loading arm 21, the slider 23 The screw 22 can travel along the arm 21 towards the Y axis; the ultrasonic seam we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com