Al-Mg-Si-Cu-Mn-Er alloy material and preparation method thereof

A technology of al-mg-si-cu-mn-er and al-mg-si-cu-mn, applied in the field of Al-Mg-Si-Cu-Mn-Er alloy material and its preparation, can solve the unseen Any problems such as reports, to achieve the effect of uniform grain size distribution, improved comprehensive performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment prepares Al-Mg-Si-Cu-Mn-0.15Er alloy material according to the following steps:

[0042] Step 1: Preparation of Alloy Ingot

[0043] 1a, ingredients: according to the mass percentage of 97.45% Al, 0.9% Mg, 0.6% Si, 0.7% Cu, 0.2% Mn and 0.15% Er, weigh 1142.5g metal Al (purity is 99.99%), 23.2gAl-50.38% Mg master alloy, 71.4gAl-10.92%Si master alloy, 25gAl-10.4%Mn master alloy, 18.2gAl-50.02%Cu master alloy and 19.7gAl-9.92%Er master alloy are batched, and the total mass of the batch is 1300g;

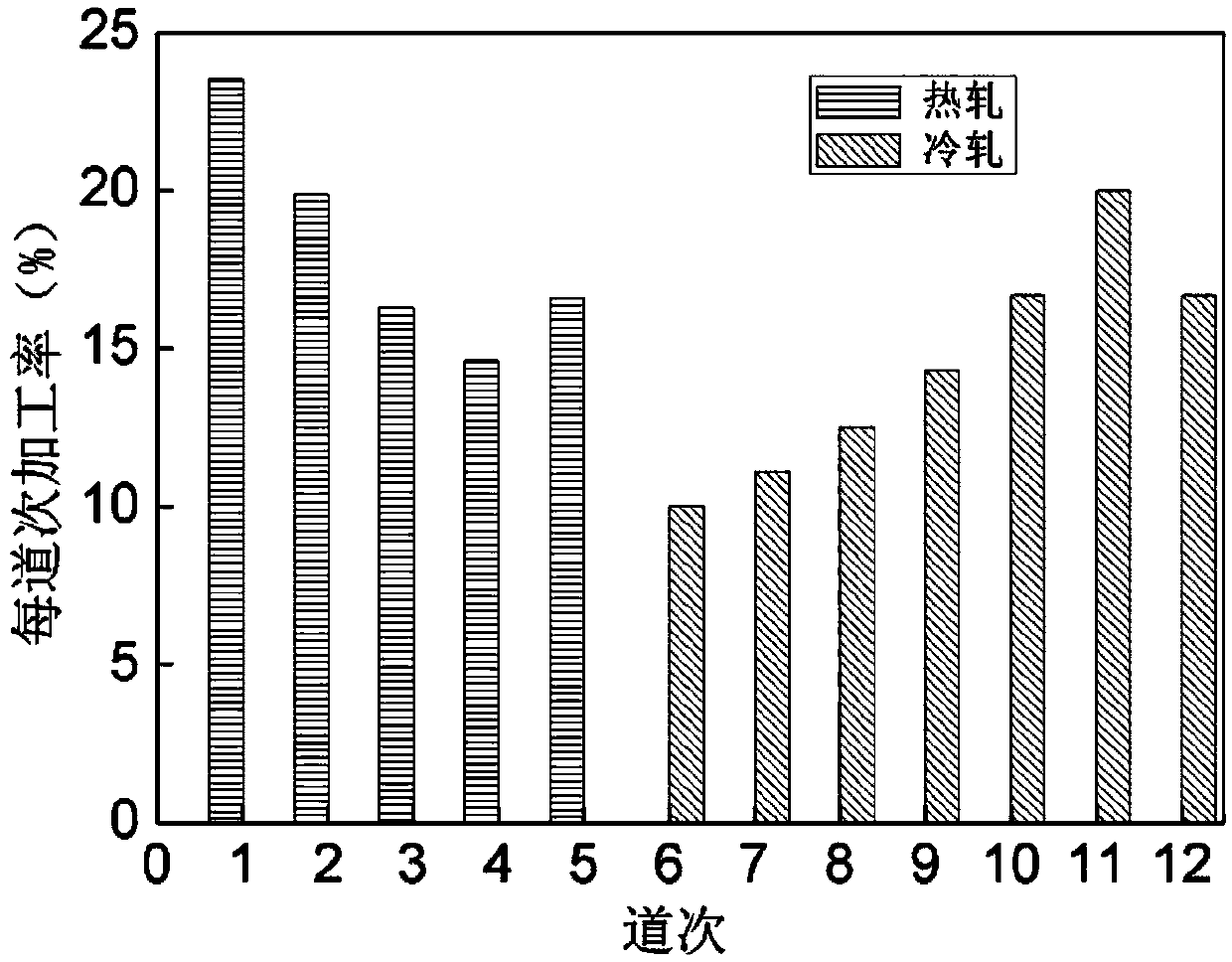

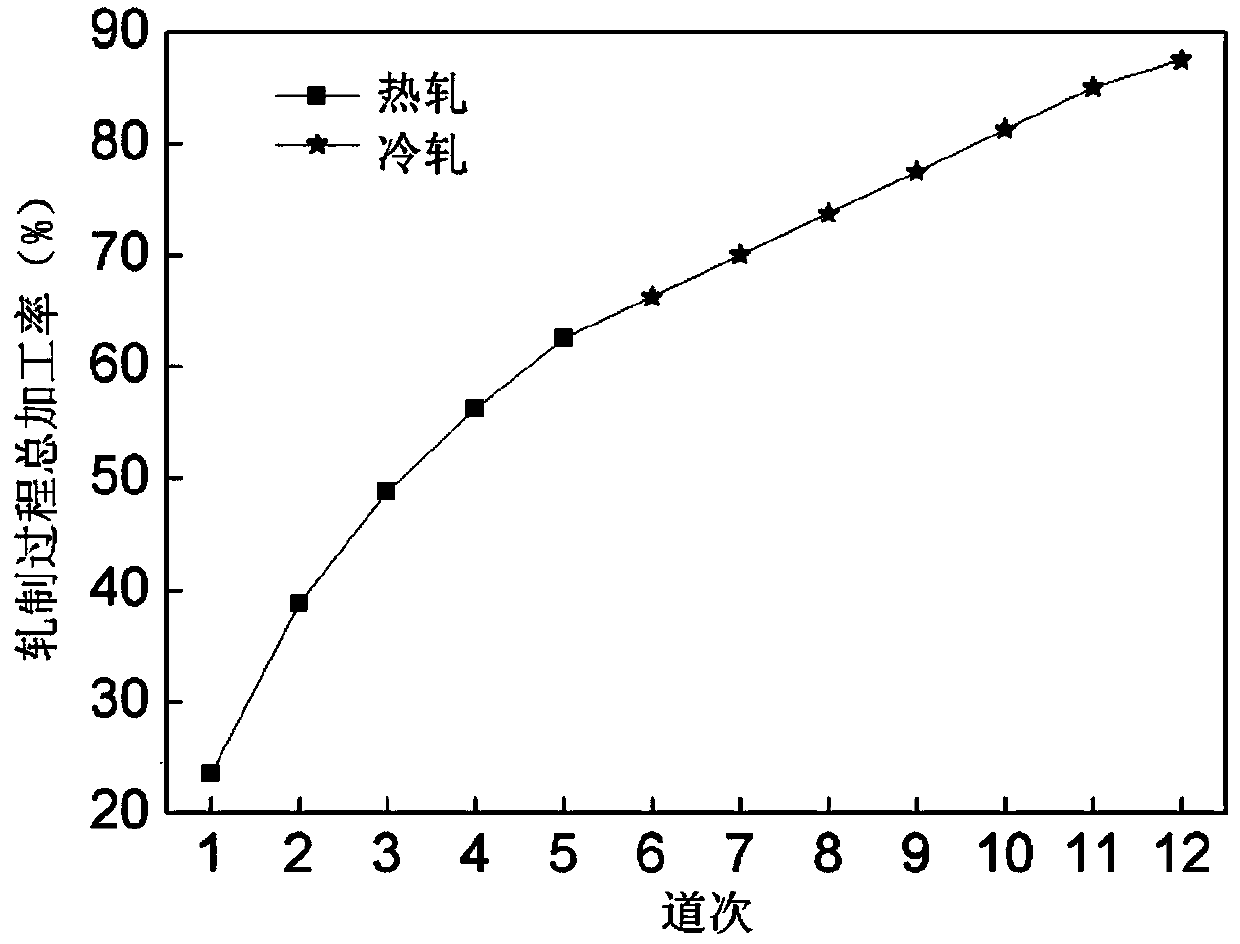

[0044] 1b. Melting: First, add metal 1142.5g Al, 25g Al-Mn master alloy, 71.4g Al-Si master alloy and 18.2g Al-Cu master alloy as raw material group A into a crucible preheated to 280°C, and heat to 730°C, constant temperature until raw material group A softens and collapses (5 minutes in this embodiment), sprinkle 6.5g of covering agent on the surface of raw material group A; continue to keep constant temperature until raw material group A is completely melted, ...

Embodiment 2

[0057] This embodiment prepares the Al-Mg-Si-Cu-Mn-0.3Er alloy material according to the same steps as in Example 1, the difference is that in step 1a, 97.3% Al, 0.9% Mg, 0.6% Si, 0.7% Cu, 0.2 The mass percent of %Mn and 0.3% Er, weighing 1122.8g metal Al (purity is 99.99%), 23.2gAl-50.38%Mg master alloy, 71.4gAl-10.92%Si master alloy, 25gAl-10.4%Mn master alloy, 18.2 gAl-50.02%Cu master alloy and 39.4gAl-9.92%Er master alloy are batched, and the total mass of the batch is 1300g;

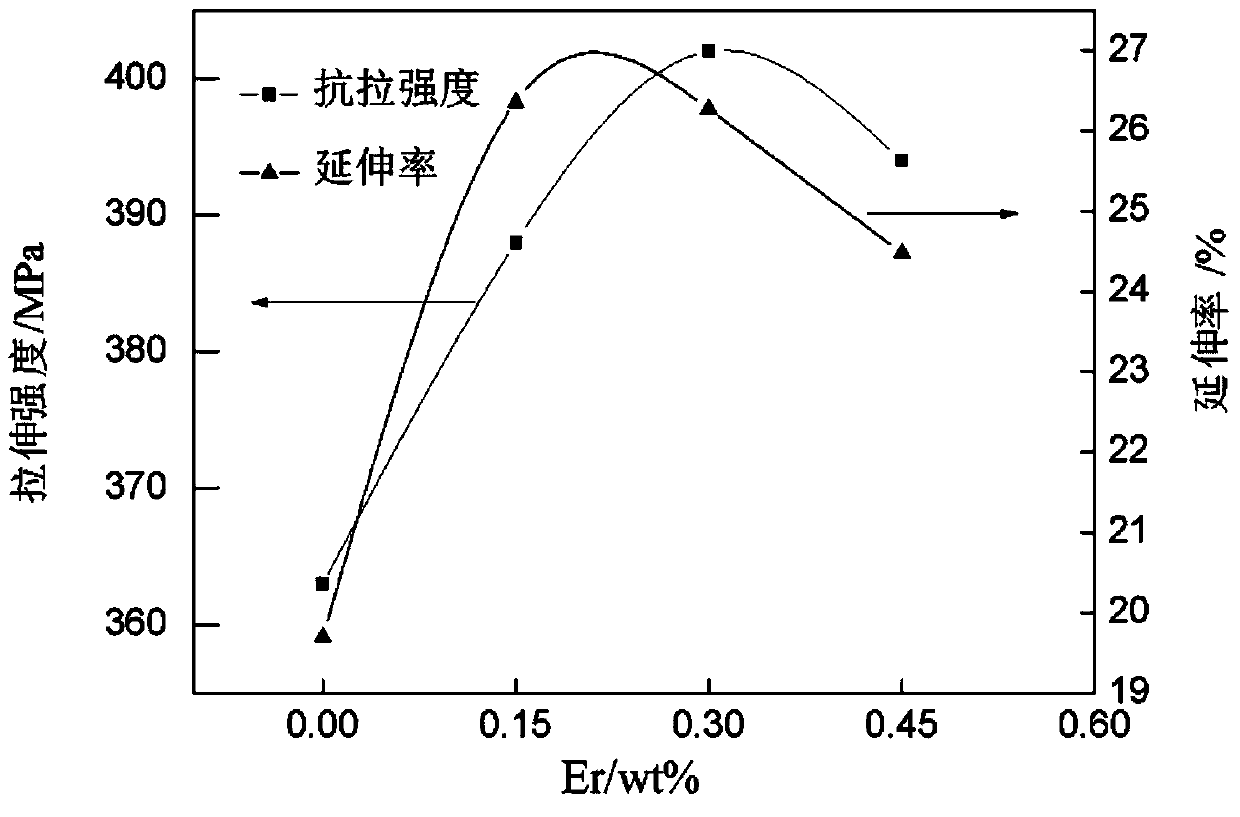

[0058] Carry out room temperature tensile test to Al-Mg-Si-Cu-Mn-0.3Er alloy material by the same method of embodiment 1, gained mechanical property index: tensile strength is 402MPa, yield strength is 378MPa, elongation is 26.27%, See Table 1 for details.

Embodiment 3

[0060] This embodiment prepares the Al-Mg-Si-Cu-Mn-0.45Er alloy material according to the same steps as in Example 1, the difference is that in step 1a, 97.15% Al, 0.9% Mg, 0.6% Si, 0.7% Cu, 0.2 The mass percentage of %Mn and 0.45% Er, weighing 1103.1g metal Al (purity is 99.99%), 23.2gAl-50.38%Mg master alloy, 71.4gAl-10.92%Si master alloy, 25gAl-10.4%Mn master alloy, 18.2 gAl-50.02%Cu master alloy and 59.1gAl-9.92%Er master alloy are batched, and the total mass of the batch is 1300g;

[0061] Carry out the tensile test at room temperature to Al-Mg-Si-Cu-Mn-0.45Er alloy material by the same method of embodiment 1, gained mechanical property index: tensile strength is 394MPa, yield strength is 369MPa, elongation is 24.48%, See Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com