A method for preventing oxide slag from adhering to crucible during intermediate frequency furnace smelting

A technology for avoiding oxidation and intermediate frequency furnace, applied in the field of metallurgy, can solve the problems such as effective removal or avoidance of intermediate frequency furnace, and achieve the effect of fast slag removal process, protection from damage, and guarantee of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take the 1.5T intermediate frequency furnace as an example. According to the calculated amount of steel material, 1000kg of material is prepared, of which 200kg of steel material is reserved;

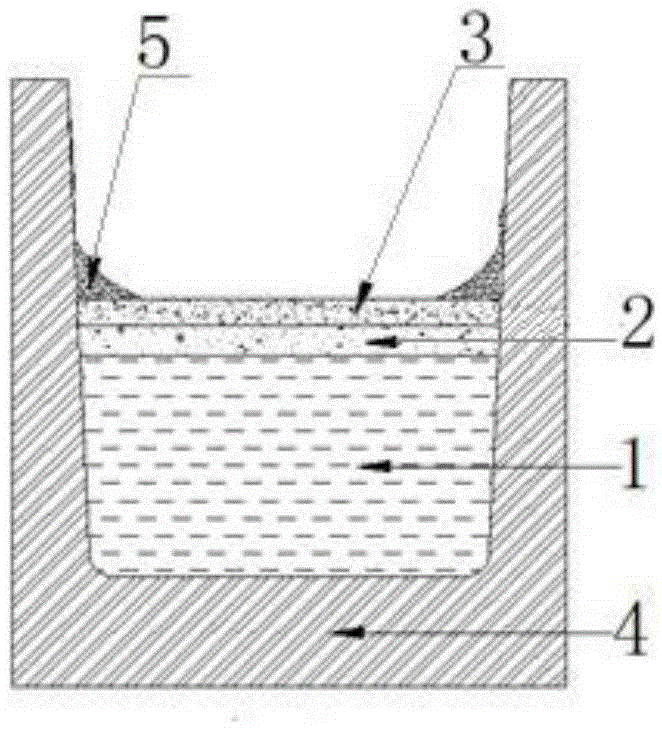

[0037] When using an intermediate frequency furnace for smelting production, first add 800kg of steel material to melt, and when the solid slag layer 3 is formed on the molten steel, sprinkle lime powder 5 on the slag layer 3 along the wall of the crucible 4, so that the lime powder 5 accumulates on the crucible. At the edge of the slag layer 3, the height of lime powder accumulated on the crucible wall is about 1.1 times the height of the solid slag layer and the liquid slag layer; figure 1 shown.

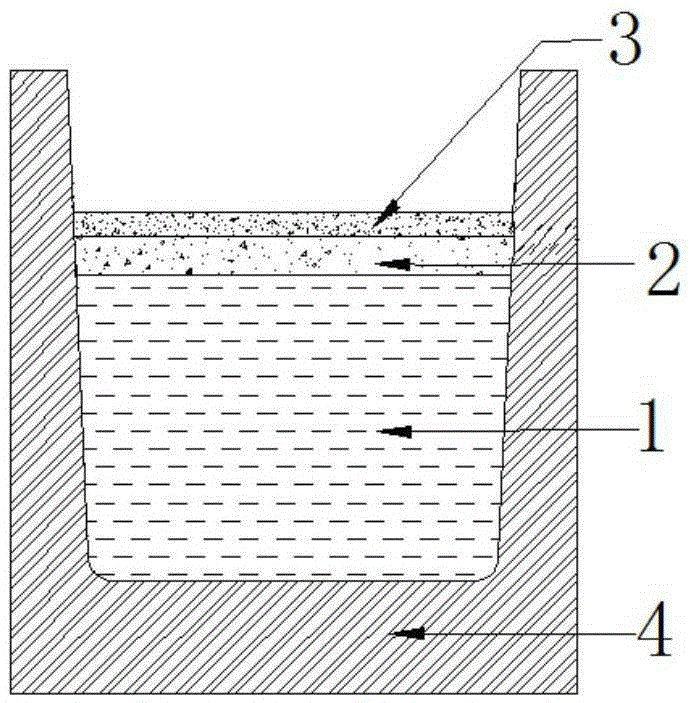

[0038] Then add the reserved 200kg iron and steel material, and the added iron and steel material will make the liquid steel surface push the slag layer to float up, such as figure 2 shown. The lime powder reacts with the oxidized slag at high temperature to produce bubbles, whic...

Embodiment 2

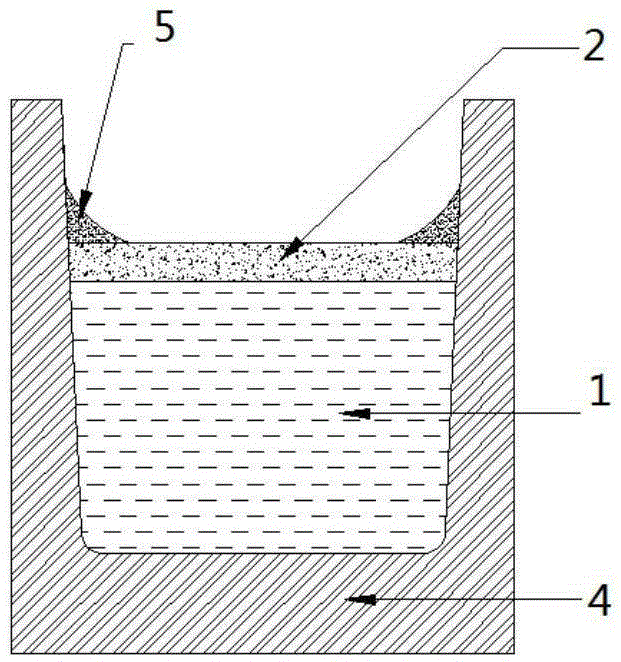

[0041] Take the 1.5T intermediate frequency furnace as an example. According to the calculated steel material weight of 1000kg, prepare materials, of which 300kg of steel material is reserved; when using intermediate frequency furnace for smelting production, first add 700kg of steel material for melting, when the liquid slag layer 2 is formed on the molten steel, the slag along the crucible wall Lime powder is sprinkled into the layer, so that the lime powder 5 is piled up on the edge of the slag layer, and the height of the lime powder 5 piled up on the crucible wall is 1.2 times the height of the liquid slag layer 2; image 3 shown;

[0042] Subsequent operations are the same as in Example 1. The added steel material makes the molten steel surface push the slag layer to float up, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com