Normal pressure method coking coal and ore powder molding binder and molding method

A molding adhesive and molding method technology, applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of fine powder loss, waste, etc., and achieve extremely easy processing and production, formula science, extremely Easy to grasp effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

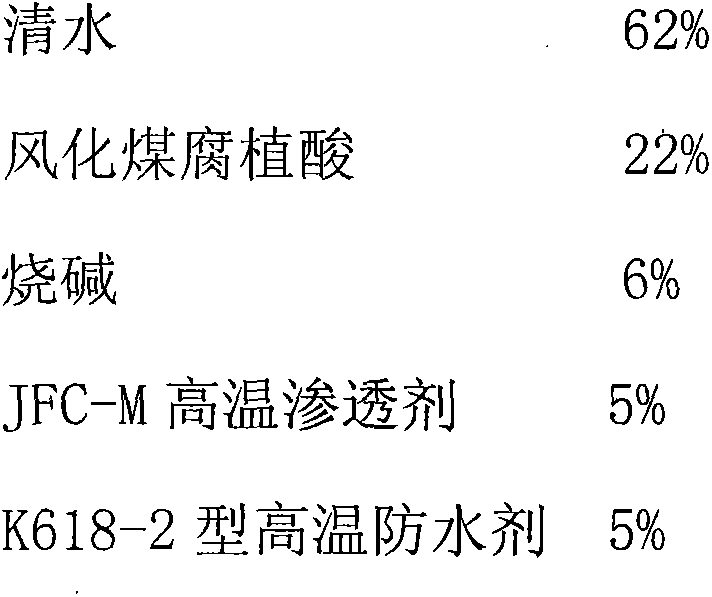

[0025] 1) The preparation method of the binder is based on the production of 200kg of binder:

[0026] Take 124kg of clear water, accounting for 62% of the formula, 44kg of weathered coal humic acid, accounting for 22% of the formula, 12kg of caustic soda, accounting for 6% of the formula, 10kg of JFC-M high-temperature penetrating agent, accounting for 5% of the formula, and 10kg of high-temperature waterproofing agent. Accounting for 5% of the formula, the preparation method is as follows: Step 1, put clean water into the reactor and heat it to 60°C; Step 2, put weathered coal humic acid and caustic soda into the heated clean water and stir, and continue to heat up for 30 minutes to 85°C ℃; step 3, add JF-M high-temperature penetrating agent and K618-2 type high-temperature waterproofing agent to step 2 and keep warm for 20 minutes, then naturally cool to 50 ℃, filter and take the liquid to obtain the finished product; step 4, put the Put the mixture into the storage tank an...

Embodiment 2

[0030] 1) The preparation method of the binder is based on the production of 200kg of binder:

[0031] Take 124kg of clear water, accounting for 62% of the formula, 44kg of weathered coal humic acid, accounting for 22% of the formula, 12kg of caustic soda, accounting for 6% of the formula, 10kg of JFC-M high-temperature penetrating agent, accounting for 5% of the formula, and 10kg of high-temperature waterproofing agent. Accounting for 5% of the formula, the preparation method is as follows: Step 1, put clean water into the reactor and heat it to 60°C; Step 2, put weathered coal humic acid and caustic soda into the heated clean water and stir, and continue to heat up for 30 minutes to 85°C ℃; step 3, add JF-M high-temperature penetrating agent and K618-2 type high-temperature waterproofing agent to step 2 and keep warm for 20 minutes, then naturally cool to 55 ℃, filter and take the liquid to obtain the finished product; step 4, put the Put the mixture into the storage tank an...

Embodiment 3

[0035] 1) The preparation method of the binder is based on the production of 300kg of binder:

[0036] Take 186kg of clear water, accounting for 62% of the formula, 66kg of weathered coal humic acid, accounting for 22% of the formula, 18kg of caustic soda, accounting for 6% of the formula, 15kg of JFC-M high-temperature penetrating agent, accounting for 5% of the formula, and 15kg of high-temperature waterproofing agent. Accounting for 5% of the formula, the preparation method is as follows: Step 1, put clean water into the reactor and heat it to 60°C; Step 2, put weathered coal humic acid and caustic soda into the heated clean water and stir, and continue to heat up for 30 minutes to 85°C ℃; step 3, add JF-M high-temperature penetrating agent and K618-2 type high-temperature waterproofing agent to step 2 and keep warm for 20 minutes, then naturally cool to 60 ℃, filter and take the liquid to obtain the finished product; step 4, put the Put the mixture into the storage tank an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com