Micro-nano orderly through-hole array metal film sensor based on piezoelectric substrate sheet and manufacturing method thereof

A piezoelectric substrate and metal film technology, applied in the field of sensors, can solve problems such as pattern distortion, and achieve the effect of reducing transfer printing, good elasticity and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

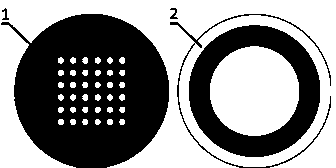

[0038] Such as Figure 1-2 As shown, the present invention is based on the micro-nano ordered through-hole array metal thin film sensor based on the piezoelectric substrate sheet. , the upper and lower metal films are attached to both sides of the quartz crystal plate,

[0039] Such as image 3 , a preferred implementation example of the present invention comprises the following steps:

[0040] S1: Make a composite elastic stamp, the detailed process is as follows.

[0041] Using photolithography technology on the silicon wafer, the ordered micro-nano column array template and the ring pattern template are prepared as the original template for further replicating the composite elastic stamp.

[0042] Drop the mixed PDMS (component A:B=1:3) prepolymer on the original template with a pipette, and set the parameters of the spin coater as follows: slow rotation at 600 rpm for 18 s, fast rotation at 3000 rpm 60 s. The spin-coated template was heated at 70 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com