Transmission type double-station punching machine with crank connecting rod structure

A crank connecting rod and transmission technology, applied in the field of machinery, can solve the problems of increased device size and cost, low working pressure, etc., and achieve the effect of compact structure, large output force and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be further described in detail below.

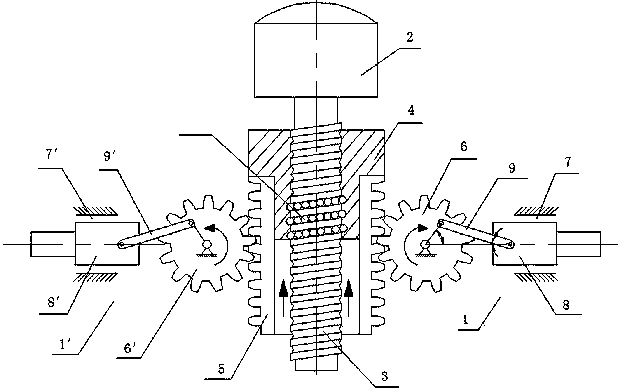

[0019] Such as figure 1 As shown, a transmission type double-station stamping machine adopting a crank-connecting rod structure of the present invention includes a machine tool (not shown) and two stamping stations 1, 1'. Two of the stamping stations 1, 1' are arranged symmetrically. However, according to the design concept of the present invention, multiple stamping stations can be arranged on one side or multiple groups of symmetrically arranged stamping stations can be arranged. A motor 2 is arranged on the machine tool, the output shaft of the motor 2 is coaxially connected with a lead screw 3 , and a nut 4 is threaded on the lead screw 3 . In this embodiment, a double-sided rack is socketed on the nut 4 , that is, a sleeve structure, and racks 5 are arranged on both sides thereof. The machine tool is also provided with two gears 6, 6' which mesh with the rack 5 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com