Curing method of three-dimensional interval conjoined fabric reinforced resin-based composite material and microwave oven for curing

A fabric-reinforced, composite material technology used in microwave heating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

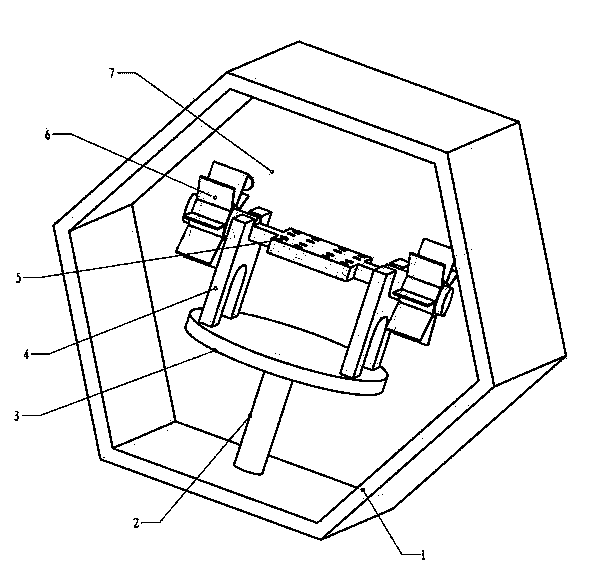

[0041] Such as figure 1 As shown, the microwave oven used in the present invention for manufacturing three-dimensional spaced conjoined fabric-reinforced resin-based composite materials includes a shell surrounded by cavity walls 1, and the shell has a regular polygonal cross-section. There is a rotating shaft 2 inside the housing, and a turntable 3 is installed on the rotating shaft. Two brackets 4 are arranged symmetrically on the turntable 3. The two brackets 4 support a mold fixing plate 5 for installing a mold. The mold is used to install a three-dimensional interval connection For the body fabric reinforced resin-based composite material preform, the trunnions on both sides of the mold fixing plate 5 extend out of the bracket 4, and the impellers 6 are respectively installed on the extended trunnions, and the positions corresponding to the impellers are on the cavity wall of the shell 1 is provided with a gas nozzle 7 for injecting nitrogen or inert gas.

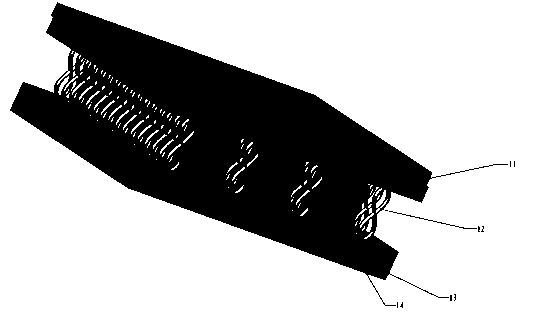

[0042] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com